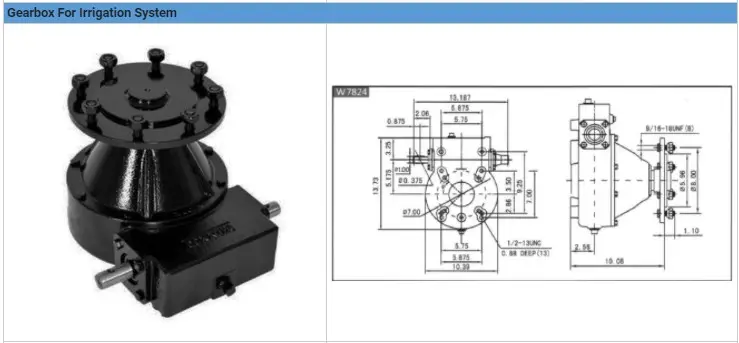

Product Description

Detailed Photos

Product Parameters

Note : It's just the typical technical data for you reference, The specification such as voltage, speed, torque, shaft can be customized by your needs. Please contact us for more details. Thanks.

Company Profile

FAQ

Q: What're your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What's your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you !

| Application: | Motor, Machinery |

|---|---|

| Function: | Speed Changing, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Longevity of Irrigation Gearboxes: Essential Maintenance Practices

Maintaining irrigation gearboxes is crucial to ensure their longevity and reliable performance. Here are essential maintenance practices:

- Lubrication: Regularly lubricate the gearbox components to minimize friction and wear. Use the recommended lubricants and follow the manufacturer's guidelines for lubrication intervals.

- Inspections: Periodically inspect the gearbox for signs of wear, damage, or leaks. Check for loose bolts, misalignment, and unusual noises during operation.

- Cleaning: Keep the gearbox clean from dirt, debris, and contaminants that could infiltrate the housing and cause damage to the gears and bearings.

- Tightening and Alignment: Check and tighten bolts, and ensure proper alignment of components to prevent excessive vibration and premature wear.

- Seal Maintenance: Maintain seals and gaskets to prevent water and contaminants from entering the gearbox, which can lead to corrosion and damage.

- Temperature Control: Monitor the operating temperature of the gearbox. Excessive heat can accelerate wear, so ensure proper ventilation and cooling.

- Replace Worn Parts: If you notice any worn or damaged components during inspections, replace them promptly to prevent further issues.

- Proper Usage: Operate the irrigation equipment within recommended load and speed limits to prevent excessive stress on the gearbox.

- Professional Maintenance: Schedule regular professional maintenance and servicing to ensure comprehensive inspections and addressing potential issues before they escalate.

By following these maintenance practices, you can extend the lifespan of irrigation gearboxes, reduce downtime, and ensure reliable performance throughout the irrigation season.

Contribution of Irrigation Gearboxes to Water Conservation in Agriculture

Irrigation gearboxes play a significant role in promoting water conservation in agricultural practices through various mechanisms:

- Precision Water Distribution: Irrigation gearboxes enable precise control over water distribution. This accuracy ensures that water is delivered directly to the crops' root zones, minimizing wastage due to overspray or runoff.

- Adjustable Flow Rates: Many irrigation gearboxes allow for adjustable flow rates, allowing farmers to tailor the irrigation process to the specific water needs of different crops and soil types.

- Programmable Scheduling: Some irrigation gearboxes are equipped with programmable timers and scheduling features. This capability enables irrigation to occur during optimal times when water evaporation rates are lower, reducing water loss.

- Zoning and Section Control: Advanced irrigation systems using gearboxes can implement zoning and section control, directing water only to areas that require it. This prevents wastage on non-cultivated or adequately irrigated areas.

- Efficient Water Management: By providing consistent and uniform water distribution, irrigation gearboxes help avoid underwatering or overwatering, both of which can lead to water waste and inefficient resource utilization.

- Reduced Runoff and Erosion: Properly calibrated irrigation systems with gearboxes minimize excessive runoff and soil erosion, preserving both water and soil resources.

- Drip Irrigation Enhancement: In drip irrigation systems, irrigation gearboxes play a role in maintaining optimal pressure levels and ensuring uniform water delivery to each plant, further enhancing water conservation.

- Adaptation to Terrain: Gear-driven irrigation systems can adapt to varying terrain, ensuring that water reaches plants situated on slopes without excessive runoff.

The application of irrigation gearboxes helps farmers use water more efficiently, minimizing waste, and contributing to sustainable agricultural practices and water conservation efforts.

Function of Irrigation Gearboxes in Agricultural Systems

An irrigation gearbox is a specialized component used in agricultural irrigation systems to control the movement of water for efficient irrigation. It plays a crucial role in distributing water to crops and fields effectively:

1. Water Flow Control: Irrigation gearboxes are designed to control the flow of water from the water source to the irrigation pipes or channels. They regulate the amount of water released and the direction in which it flows, ensuring even distribution across the entire field.

2. Valve Operation: Many irrigation systems use valves to manage water flow. Irrigation gearboxes are often integrated with these valves to open, close, or adjust them based on the irrigation schedule. The gearbox's rotational motion is translated into the linear motion needed to operate the valve mechanisms.

3. Timing and Scheduling: Some irrigation gearboxes are equipped with timers or sensors that allow for automated irrigation scheduling. The gearbox can be programmed to open or close valves at specific times, ensuring that crops receive water when needed.

4. Precision and Control: Irrigation gearboxes provide precise control over the water distribution process. This control is essential for preventing over- or under-watering, which can negatively impact crop health and yield. Proper water distribution also helps conserve water resources.

5. Adaptation to Terrain: Agricultural fields often have varying terrain and elevation changes. Irrigation gearboxes can be adjusted to accommodate different field layouts and slopes, ensuring that water reaches all areas evenly.

6. Integration with Pump Systems: In some cases, irrigation gearboxes are connected to pump systems that supply water from a water source such as a well or reservoir. The gearbox ensures that the pump operates efficiently, maintaining consistent water pressure and flow rates.

7. Maintenance and Durability: Irrigation gearboxes are designed to withstand the outdoor and agricultural environment. They are often constructed with durable materials and sealed to prevent water and debris ingress. Regular maintenance is required to ensure smooth operation and longevity.

Overall, irrigation gearboxes are essential components in agricultural irrigation systems. They enable precise control over water distribution, improve water efficiency, and contribute to the overall health and yield of crops by ensuring proper hydration.

editor by CX 2023-10-10