Product Description

UMC is the industry leader in gearbox technology. Over our 40 year history we have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. We continue to define and redefine industry standards for gearbox performance, quality, features and technology. Our gearboxes are purpose built to do the job. Never over-engineered.

UMC stands behind its products and is committed to manufacturing the best products for a global market.

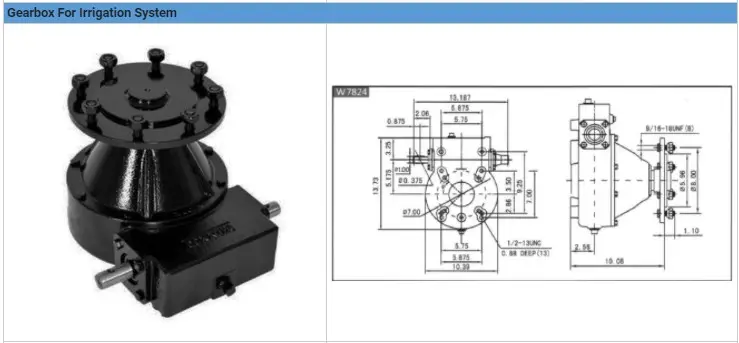

740-U 50:1 Ratio

Designed for longer spans, larger wheels, and heavier towers.

Features and Benefits

- 2.25 inch output shaft

- 50:1 gear ratio

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

740-UV 52:1 Ratio

Designed for longer spans, larger wheels and heavier towers where an extended output shaft is required.

This gearbox has all the same capabilities, features and benefits that the standard 740 has with a few tweaks. The output shaft is extended, the gear ratio is 52:1 and the input shaft is made of ductile iron with a 25° pressure angle allowing this gearbox to be used on center CHINAMFG and lateral move/ linear systems that come standard with these specifications.

Features and Benefits

- 2.25 inch extended output shaft

- 52:1 gear ratio with 25° pressure angle

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Gearbox

Designed for corner systems and lateral move carts where an extended output shaft is required

Growers typically use UMC's 760-UV gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV final drive gearbox is our largest and most durable gearbox with an extended output shaft. It features a larger-diameter bull gear than the standard 740 series to handle 20% higher torque. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- 20% more torque capacity than the standard 740

- Bronze gear optional

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

TNT-2 Gearbox

Designed for applications where the irrigation system may need to be towed

This gearbox is the perfect solution for a towable irrigation system. Growers typically prefer this gearbox over a gearbox with a towable hub. Simply disengage the worm and tow your system to its working location, then re-engage the worm and you are ready to run. The CX coupler is the perfect compliment for the TNT-2 gearbox due to the ability to control coupler disengagement at the gearbox.

The UMC patented TNT-2 final drive gearbox is designed specifically for applications where a center CHINAMFG or lateral move/ linear irrigation system needs to be towed. The gearbox provides the ability to disengage the worm gear and allows users to move systems from 1 area to another without requiring a Towable Hub add on.

Features and Benefits

- 2.25″ output shaft

- 50:1 gear ratio

- Dual input seals with triple lip output seals

- Bronze gear optional

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- 11-Bolt mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Bronze Gearbox

Designed for the most extreme conditions where an extended output shaft is required.

Growers typically use The UMC 760-UV bronze gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV Bronze final drive gearbox is our largest and most durable gearbox with an extended output shaft designed for the most extreme growing conditions. It features a high strength aluminum bronze bull gear and a heat treated steel worm gear giving it a much higher load capacity than the standard 760-UV. Additionally, this gear combination greatly reduces gear wear, extending the useful life of the gearbox. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- Bronze Gear

- Heat Treated Steel Worm Gear

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

- Also Available Assembled in the USA

CHINAMFG is the industry leader in gearbox technology. Over 37 year history they have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. CHINAMFG continue to define and redefine industry standards for gearbox performance, quality, features and technology. CHINAMFG gearboxes are purpose built to do the job. Never over-engineered.UMC stands behind its products and is committed to manufacturing the best products for a global market.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Agricultural |

|---|---|

| Function: | Speed Reduction |

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Material: | Cast Iron |

| Manipulate Way: | Semi-Automatic Manipulation |

| Customization: |

Available

| Customized Request |

|---|

Handling Different Soil and Terrain with Irrigation Gearboxes

Irrigation gearboxes are designed to effectively handle various types of soil and terrain, ensuring reliable and efficient water distribution. Here's how they adapt to different conditions:

- Variable Torque: Different soil types require varying levels of force to move irrigation equipment. Irrigation gearboxes can adjust their torque output to accommodate softer or harder soil, ensuring the equipment can move smoothly even in challenging conditions.

- Traction Control: In hilly or uneven terrains, traction can be an issue. Irrigation gearboxes are equipped with features that enhance traction, such as slip-resistant surfaces or adjustable torque settings. This prevents slippage and maintains consistent movement on different terrains.

- Controlled Speed: Different terrains may demand different speeds to ensure uniform water distribution. Irrigation gearboxes allow operators to adjust the speed according to the terrain, preventing excessive water application in certain areas and ensuring optimal coverage.

- Adaptable Design: Some irrigation gearboxes have adaptable designs, allowing for easy customization based on the specific terrain and irrigation method. This ensures that the equipment operates efficiently and effectively, regardless of the challenges presented by the terrain.

By offering versatility and adaptability, irrigation gearboxes enable farmers to navigate and irrigate different types of soil and terrains with precision, ensuring consistent water distribution and optimal crop growth.

Contribution of Irrigation Gearboxes to Water Conservation in Agriculture

Irrigation gearboxes play a significant role in promoting water conservation in agricultural practices through various mechanisms:

- Precision Water Distribution: Irrigation gearboxes enable precise control over water distribution. This accuracy ensures that water is delivered directly to the crops' root zones, minimizing wastage due to overspray or runoff.

- Adjustable Flow Rates: Many irrigation gearboxes allow for adjustable flow rates, allowing farmers to tailor the irrigation process to the specific water needs of different crops and soil types.

- Programmable Scheduling: Some irrigation gearboxes are equipped with programmable timers and scheduling features. This capability enables irrigation to occur during optimal times when water evaporation rates are lower, reducing water loss.

- Zoning and Section Control: Advanced irrigation systems using gearboxes can implement zoning and section control, directing water only to areas that require it. This prevents wastage on non-cultivated or adequately irrigated areas.

- Efficient Water Management: By providing consistent and uniform water distribution, irrigation gearboxes help avoid underwatering or overwatering, both of which can lead to water waste and inefficient resource utilization.

- Reduced Runoff and Erosion: Properly calibrated irrigation systems with gearboxes minimize excessive runoff and soil erosion, preserving both water and soil resources.

- Drip Irrigation Enhancement: In drip irrigation systems, irrigation gearboxes play a role in maintaining optimal pressure levels and ensuring uniform water delivery to each plant, further enhancing water conservation.

- Adaptation to Terrain: Gear-driven irrigation systems can adapt to varying terrain, ensuring that water reaches plants situated on slopes without excessive runoff.

The application of irrigation gearboxes helps farmers use water more efficiently, minimizing waste, and contributing to sustainable agricultural practices and water conservation efforts.

Function of Irrigation Gearboxes in Agricultural Systems

An irrigation gearbox is a specialized component used in agricultural irrigation systems to control the movement of water for efficient irrigation. It plays a crucial role in distributing water to crops and fields effectively:

1. Water Flow Control: Irrigation gearboxes are designed to control the flow of water from the water source to the irrigation pipes or channels. They regulate the amount of water released and the direction in which it flows, ensuring even distribution across the entire field.

2. Valve Operation: Many irrigation systems use valves to manage water flow. Irrigation gearboxes are often integrated with these valves to open, close, or adjust them based on the irrigation schedule. The gearbox's rotational motion is translated into the linear motion needed to operate the valve mechanisms.

3. Timing and Scheduling: Some irrigation gearboxes are equipped with timers or sensors that allow for automated irrigation scheduling. The gearbox can be programmed to open or close valves at specific times, ensuring that crops receive water when needed.

4. Precision and Control: Irrigation gearboxes provide precise control over the water distribution process. This control is essential for preventing over- or under-watering, which can negatively impact crop health and yield. Proper water distribution also helps conserve water resources.

5. Adaptation to Terrain: Agricultural fields often have varying terrain and elevation changes. Irrigation gearboxes can be adjusted to accommodate different field layouts and slopes, ensuring that water reaches all areas evenly.

6. Integration with Pump Systems: In some cases, irrigation gearboxes are connected to pump systems that supply water from a water source such as a well or reservoir. The gearbox ensures that the pump operates efficiently, maintaining consistent water pressure and flow rates.

7. Maintenance and Durability: Irrigation gearboxes are designed to withstand the outdoor and agricultural environment. They are often constructed with durable materials and sealed to prevent water and debris ingress. Regular maintenance is required to ensure smooth operation and longevity.

Overall, irrigation gearboxes are essential components in agricultural irrigation systems. They enable precise control over water distribution, improve water efficiency, and contribute to the overall health and yield of crops by ensuring proper hydration.

editor by CX 2024-01-26