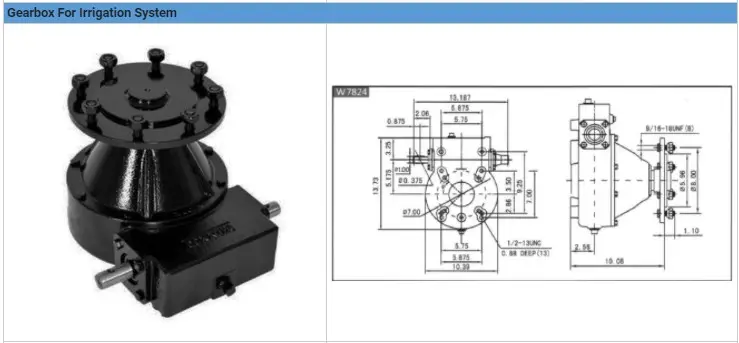

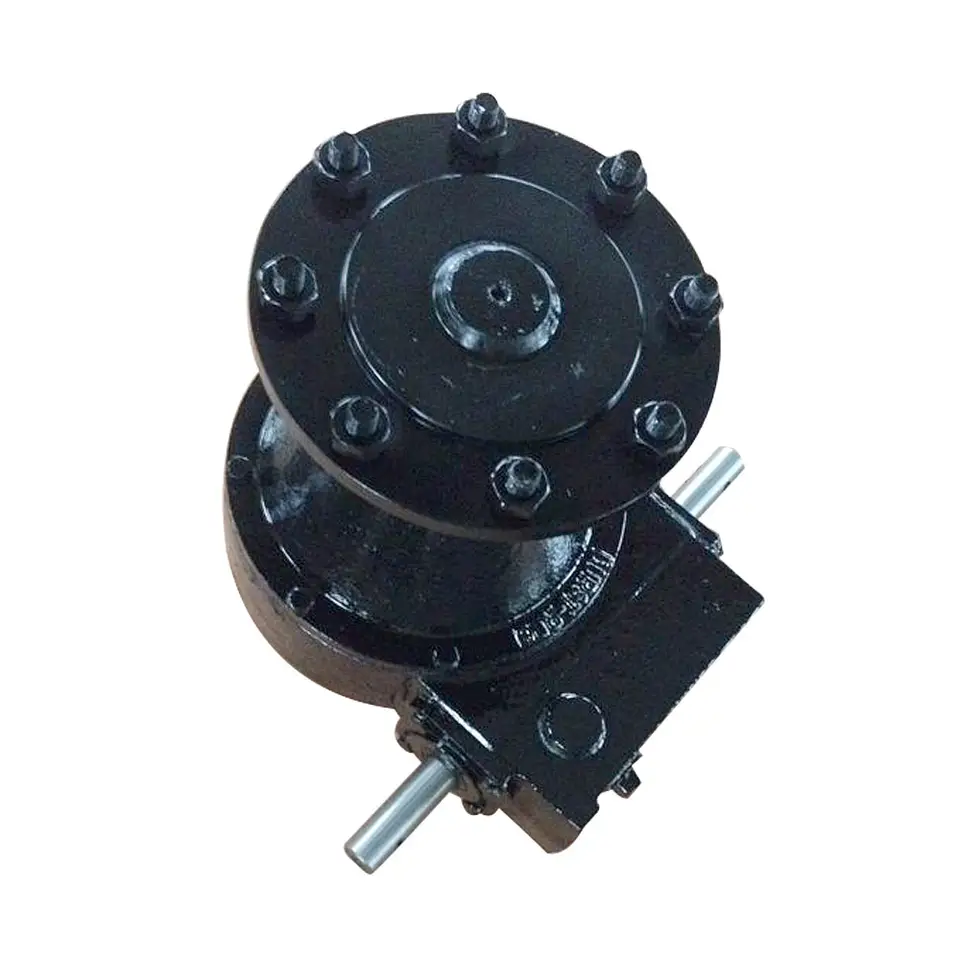

Product Description

Farm Irrigation Systems pto Gearbox Shafts

Product Description

Here is our advantages when compare to similar products from China:

| 1. Large output torque |

| 2. Safe, reliable, economical, and durable |

| 3. Stable transmission, quiet operation |

| 4. High modularization design, may equip with various outer power inputs conveniently. The same machine type may equip with various power motors. It is easy to realize the combination and junction between every machine type |

| 5. Form of installation: The position to be installed is not limited |

| 6. High strength, compact the box body of high strength cast iron, gear and gear shaft adopt the gas carbonization, quenching, and fine grinding process, therefore the bearing capacity of unit volume is high |

| 7. Long life: Under the condition of the correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life of the main parts speed reducer(except wearing parts)should not be less than 20000 hours |

| 8. Low noise: Because the main parts of the speed reducer are processed, and tested critically, therefore the noise of the speed reducer is low |

Product Specifications

| ITEM | HN25710.131.00 |

| Ratio | 1.31:1 |

| Teeth | 16/21 |

| Module | 7.0 |

| Power | 100 |

| Rated Input | 600rpm |

| Input/Output Description | 8-Φ48X Φ42X8 |

| Weight(N.W) | 58Kg |

Certifications

Equipment

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of " High Quality, Customers'Satisfaction", using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT'S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.How long is your delivery time and shipment?

30-45days

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Cultivator Gearbox |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery |

| Material: | 20 Crmnti |

| Power Source: | Agricultural Machinery,Farm Tractor |

| Weight: | 22-60g |

| After-sales Service: | Online Support |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Factors in Selecting the Right Irrigation Gearbox

Choosing the appropriate irrigation gearbox involves considering several key factors to ensure optimal performance and water distribution efficiency:

- Irrigation Method: Different irrigation methods (pivot, linear, drip, etc.) have specific gearbox requirements. The gearbox must match the motion and distribution pattern of the chosen method.

- Load Capacity: The gearbox should be able to handle the load imposed by the irrigation equipment, including the weight of pipes, hoses, and sprinklers.

- Adjustability: For pivot and linear irrigation, the gearbox should allow for precise adjustments to control the radius of coverage.

- Environmental Conditions: The gearbox should be designed to withstand exposure to water, moisture, dirt, and varying weather conditions.

- Speed and Torque: The gearbox's speed and torque specifications must match the requirements of the irrigation system's movement and water distribution needs.

- Durability: The gearbox should have a robust construction to ensure a long lifespan, even in challenging agricultural environments.

- Efficiency: An efficient gearbox minimizes energy consumption, contributing to overall system efficiency.

- Compatibility: The gearbox must be compatible with the other components of the irrigation system, including motors, control systems, and actuators.

- Maintenance: Easy access for maintenance and servicing is crucial to prevent downtime during critical watering periods.

- Cost: Balancing performance and cost is essential to ensure that the selected gearbox provides the best value for the investment.

By carefully evaluating these factors, farmers and agricultural professionals can choose the right irrigation gearbox that meets the specific needs of their irrigation system and contributes to efficient water distribution and crop growth.

Contribution of Irrigation Gearboxes to Water Conservation in Agriculture

Irrigation gearboxes play a significant role in promoting water conservation in agricultural practices through various mechanisms:

- Precision Water Distribution: Irrigation gearboxes enable precise control over water distribution. This accuracy ensures that water is delivered directly to the crops' root zones, minimizing wastage due to overspray or runoff.

- Adjustable Flow Rates: Many irrigation gearboxes allow for adjustable flow rates, allowing farmers to tailor the irrigation process to the specific water needs of different crops and soil types.

- Programmable Scheduling: Some irrigation gearboxes are equipped with programmable timers and scheduling features. This capability enables irrigation to occur during optimal times when water evaporation rates are lower, reducing water loss.

- Zoning and Section Control: Advanced irrigation systems using gearboxes can implement zoning and section control, directing water only to areas that require it. This prevents wastage on non-cultivated or adequately irrigated areas.

- Efficient Water Management: By providing consistent and uniform water distribution, irrigation gearboxes help avoid underwatering or overwatering, both of which can lead to water waste and inefficient resource utilization.

- Reduced Runoff and Erosion: Properly calibrated irrigation systems with gearboxes minimize excessive runoff and soil erosion, preserving both water and soil resources.

- Drip Irrigation Enhancement: In drip irrigation systems, irrigation gearboxes play a role in maintaining optimal pressure levels and ensuring uniform water delivery to each plant, further enhancing water conservation.

- Adaptation to Terrain: Gear-driven irrigation systems can adapt to varying terrain, ensuring that water reaches plants situated on slopes without excessive runoff.

The application of irrigation gearboxes helps farmers use water more efficiently, minimizing waste, and contributing to sustainable agricultural practices and water conservation efforts.

Handling Variations in Water Pressure and Flow with Irrigation Gearboxes

Irrigation gearboxes are designed to effectively handle variations in water pressure and flow, ensuring consistent and uniform water distribution across the irrigated area. Here's how they accomplish this:

- Pressure Regulation: Many irrigation gearboxes are equipped with pressure regulation mechanisms. These mechanisms can adjust the gearbox's internal components to accommodate changes in water pressure, maintaining a steady output regardless of fluctuations.

- Flow Control: Irrigation gearboxes can control the flow rate of water by adjusting the rotational speed of the output shaft. This control allows for precise water distribution, even when the input water flow rate changes.

- Optimized Gearing: The gearbox's internal gearing system is designed to provide consistent performance even under varying loads. High-quality materials and precision engineering ensure that the gearbox can handle different conditions without compromising efficiency.

- Feedback Mechanisms: Some advanced irrigation systems include feedback mechanisms that monitor water pressure and flow in real time. These feedback signals can be used to automatically adjust the gearbox's settings for optimal performance.

Overall, irrigation gearboxes are engineered to maintain reliable and consistent water distribution regardless of changes in water pressure and flow. This capability is crucial for ensuring that crops, plants, and landscapes receive the required amount of water for healthy growth.

editor by CX 2024-03-27

China Best Sales CZPT Wheel Gearbox on Zimmatic Center CZPT and Lateral Move Irrigation System with Hot selling

Product Description

UMC is the industry leader in gearbox technology. Over our 40 year history we have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. We continue to define and redefine industry standards for gearbox performance, quality, features and technology. Our gearboxes are purpose built to do the job. Never over-engineered.

UMC stands behind its products and is committed to manufacturing the best products for a global market.

740-U 50:1 Ratio

Designed for longer spans, larger wheels, and heavier towers.

Features and Benefits

- 2.25 inch output shaft

- 50:1 gear ratio

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

740-UV 52:1 Ratio

Designed for longer spans, larger wheels and heavier towers where an extended output shaft is required.

This gearbox has all the same capabilities, features and benefits that the standard 740 has with a few tweaks. The output shaft is extended, the gear ratio is 52:1 and the input shaft is made of ductile iron with a 25° pressure angle allowing this gearbox to be used on center CHINAMFG and lateral move/ linear systems that come standard with these specifications.

Features and Benefits

- 2.25 inch extended output shaft

- 52:1 gear ratio with 25° pressure angle

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Gearbox

Designed for corner systems and lateral move carts where an extended output shaft is required

Growers typically use UMC's 760-UV gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV final drive gearbox is our largest and most durable gearbox with an extended output shaft. It features a larger-diameter bull gear than the standard 740 series to handle 20% higher torque. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- 20% more torque capacity than the standard 740

- Bronze gear optional

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

TNT-2 Gearbox

Designed for applications where the irrigation system may need to be towed

This gearbox is the perfect solution for a towable irrigation system. Growers typically prefer this gearbox over a gearbox with a towable hub. Simply disengage the worm and tow your system to its working location, then re-engage the worm and you are ready to run. The CX coupler is the perfect compliment for the TNT-2 gearbox due to the ability to control coupler disengagement at the gearbox.

The UMC patented TNT-2 final drive gearbox is designed specifically for applications where a center CHINAMFG or lateral move/ linear irrigation system needs to be towed. The gearbox provides the ability to disengage the worm gear and allows users to move systems from 1 area to another without requiring a Towable Hub add on.

Features and Benefits

- 2.25″ output shaft

- 50:1 gear ratio

- Dual input seals with triple lip output seals

- Bronze gear optional

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- 11-Bolt mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Bronze Gearbox

Designed for the most extreme conditions where an extended output shaft is required.

Growers typically use The UMC 760-UV bronze gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV Bronze final drive gearbox is our largest and most durable gearbox with an extended output shaft designed for the most extreme growing conditions. It features a high strength aluminum bronze bull gear and a heat treated steel worm gear giving it a much higher load capacity than the standard 760-UV. Additionally, this gear combination greatly reduces gear wear, extending the useful life of the gearbox. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- Bronze Gear

- Heat Treated Steel Worm Gear

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

- Also Available Assembled in the USA

CHINAMFG is the industry leader in gearbox technology. Over 37 year history they have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. CHINAMFG continue to define and redefine industry standards for gearbox performance, quality, features and technology. CHINAMFG gearboxes are purpose built to do the job. Never over-engineered.UMC stands behind its products and is committed to manufacturing the best products for a global market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Agricultural |

|---|---|

| Function: | Speed Reduction |

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Material: | Cast Iron |

| Manipulate Way: | Semi-Automatic Manipulation |

| Customization: |

Available

| Customized Request |

|---|

Precise Control of Irrigation Equipment with Gearboxes

Irrigation gearboxes play a crucial role in ensuring precise control of irrigation equipment, especially in pivot and linear irrigation systems. Here's how they achieve this:

- Ratio and Speed Control: Gearboxes are designed to provide precise control over the rotational speed and direction of motion. This allows farmers to adjust the speed at which the irrigation equipment moves along the designated path.

- Adjustability: Gearboxes often come with adjustable settings that enable farmers to customize the angle and radius of coverage. In pivot irrigation, for instance, gearboxes control the pivot point, allowing for varying degrees of rotation and precise positioning of sprinklers.

- Positional Accuracy: Gearboxes ensure accurate positioning of irrigation equipment by translating the rotational motion of the motor into linear movement along a specific path. This accuracy is essential to evenly distribute water across the field and avoid over-watering or under-watering.

- Repeatability: Gearboxes provide consistent and repeatable movement, ensuring that irrigation equipment follows the same path with each cycle. This repeatability is vital for maintaining uniform water distribution and optimizing crop growth.

- Integration with Control Systems: Many modern irrigation systems incorporate advanced control systems that can precisely adjust the gearbox's settings based on factors such as soil moisture levels, weather conditions, and specific crop requirements.

- Automation: Gearboxes can be integrated into automated irrigation systems that can be programmed to start, stop, and adjust movement patterns automatically. This level of automation ensures precise and efficient water distribution without the need for constant manual intervention.

By providing the means to control speed, angle, and direction, irrigation gearboxes enable farmers to achieve accurate and efficient water distribution, resulting in healthier crops and optimized water usage.

Disadvantages and Limitations of Using Irrigation Gear Systems

While irrigation gear systems offer numerous benefits, they also come with some disadvantages and limitations:

- Cost: Irrigation gear systems can be relatively expensive to install and maintain, especially when compared to manual irrigation methods. The initial investment includes the cost of gearboxes, motors, pumps, and other associated components.

- Maintenance: Regular maintenance is essential to keep irrigation gear systems functioning properly. Gearboxes and other mechanical components require periodic checks, lubrication, and potential repairs, which can add to maintenance costs and downtime.

- Complexity: The complexity of irrigation gear systems can pose challenges for farmers who are not familiar with mechanical systems. Troubleshooting issues or making adjustments might require technical expertise.

- Dependence on Power: Many irrigation gear systems rely on electricity to operate, which can be a limitation in areas with unreliable power sources or during power outages.

- Environmental Impact: Depending on the energy source used, irrigation gear systems can have an environmental impact, especially if they are powered by non-renewable resources.

- Site Limitations: The suitability of irrigation gear systems depends on the layout and terrain of the field. Steep slopes, rocky terrain, or irregular field shapes might limit the effectiveness of these systems.

Despite these limitations, proper planning, maintenance, and operational considerations can help mitigate these challenges, allowing farmers to harness the benefits of irrigation gear systems while addressing their drawbacks.

Variations in Irrigation Gearbox Designs for Specific Irrigation Methods

Irrigation gearbox designs can vary based on the specific irrigation methods they are intended to be used with. Different irrigation techniques require different gearboxes to optimize water distribution. Here are some examples of variations in irrigation gearbox designs:

- Pivot Irrigation: Pivot irrigation systems use linear move or center pivot systems to distribute water in a circular pattern. Gearboxes for pivot irrigation often have a high degree of angular adjustability to accommodate the circular motion. They may also feature specialized seals and coatings to withstand exposure to water and environmental factors.

- Linear Irrigation: Linear irrigation involves moving the water distribution equipment along a straight line. Gearboxes for linear irrigation systems need to provide smooth and precise linear motion. They may incorporate linear actuators or guides to ensure accurate movement.

- Drip Irrigation: Drip irrigation delivers water directly to the plant root zone. Gearboxes for drip irrigation may be part of valve control systems that regulate the water flow to individual drip lines. These gearboxes need to be compact and efficient in controlling the flow rate.

- Sprinkler Irrigation: Sprinkler systems disperse water over the cultivated area in a spray pattern. Gearboxes for sprinkler irrigation may be used in the rotating heads of sprinklers. They need to provide reliable rotation and positioning for even water coverage.

- Subsurface Irrigation: Subsurface irrigation delivers water below the soil surface. Gearboxes for subsurface irrigation may be used in valve systems controlling the water release from underground pipes. They require durability and resistance to soil and moisture.

These variations in irrigation gearbox designs reflect the diverse needs of different irrigation methods. Customized gearbox designs help ensure efficient and effective water distribution for various agricultural and landscaping applications.

editor by CX 2024-03-26

China factory F Series Horizontal Shaft Irrigation Gearbox with comer gearbox

Product Description

Detailed Photos

Product Description

High modular design, flexible mounting mode.

Integrated casting housing,compact dimension, stable transmitting and low noise level.

Perfect oil leakage preventing makes the good sealings and can be used in wide range of industry.

Advanced gear grinding and modified profile, high loading support and more safe operation.

High efficiency and save power.

Save cost and low maintenance.

Main applied for

Harbor and shipping

Hoist and transport

Electric power

Coal mining

Cement and construction

Paper and light industry

Product Parameters

|

Housing material |

Cast iron/Ductile iron |

|

Housing hardness |

HBS190-240 |

|

Gear material |

20CrMnTi alloy steel |

|

Surface hardness of gears |

HRC58°~62 ° |

|

Gear core hardness |

HRC33~40 |

|

Input / Output shaft material |

42CrMo alloy steel |

|

Input / Output shaft hardness |

HRC25~30 |

|

Machining precision of gears |

accurate grinding, 6~5 Grade |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat treatment |

tempering, cementiting, quenching, etc. |

|

Efficiency |

94%~96% (depends on the transmission stage) |

|

Noise (MAX) |

60~68dB |

|

Temp. rise (MAX) |

40°C |

|

Temp. rise (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Brand of bearings |

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, INA, NSK. |

|

Brand of oil seal |

CHINAMFG --- ZheJiang or other brands requested |

Our Advantages

Packaging & Shipping

Certifications

Company Profile

Xihu (West Lake) Dis.ng Transmission Equipment Co., Ltd. located HangZhou city, ZHangZhoug, as 1 professional

manufacturer and exporter of cycloidal pin wheel reducer,worm reducer, gear reducer, gearbox ,

AC motor and relative spare parts, owns rich experience in this line for many years.

We are 1 direct factory, with advanced production equipment, the strong development team and

producing capacity to offer quality products for customers.

Our products widely served to various industries of Metallurgy, Chemicals, textile,medicine,wooden

etc. Main markets: China, Africa,Australia,Vietnam, Turkey,Japan, Korea, Philippines...

Welcome to ask us any questions, good offer always for you for long term business.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.

Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q:How to choose a gearbox which meets your requirement?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

Factors in Selecting the Right Irrigation Gearbox

Choosing the appropriate irrigation gearbox involves considering several key factors to ensure optimal performance and water distribution efficiency:

- Irrigation Method: Different irrigation methods (pivot, linear, drip, etc.) have specific gearbox requirements. The gearbox must match the motion and distribution pattern of the chosen method.

- Load Capacity: The gearbox should be able to handle the load imposed by the irrigation equipment, including the weight of pipes, hoses, and sprinklers.

- Adjustability: For pivot and linear irrigation, the gearbox should allow for precise adjustments to control the radius of coverage.

- Environmental Conditions: The gearbox should be designed to withstand exposure to water, moisture, dirt, and varying weather conditions.

- Speed and Torque: The gearbox's speed and torque specifications must match the requirements of the irrigation system's movement and water distribution needs.

- Durability: The gearbox should have a robust construction to ensure a long lifespan, even in challenging agricultural environments.

- Efficiency: An efficient gearbox minimizes energy consumption, contributing to overall system efficiency.

- Compatibility: The gearbox must be compatible with the other components of the irrigation system, including motors, control systems, and actuators.

- Maintenance: Easy access for maintenance and servicing is crucial to prevent downtime during critical watering periods.

- Cost: Balancing performance and cost is essential to ensure that the selected gearbox provides the best value for the investment.

By carefully evaluating these factors, farmers and agricultural professionals can choose the right irrigation gearbox that meets the specific needs of their irrigation system and contributes to efficient water distribution and crop growth.

Disadvantages and Limitations of Using Irrigation Gear Systems

While irrigation gear systems offer numerous benefits, they also come with some disadvantages and limitations:

- Cost: Irrigation gear systems can be relatively expensive to install and maintain, especially when compared to manual irrigation methods. The initial investment includes the cost of gearboxes, motors, pumps, and other associated components.

- Maintenance: Regular maintenance is essential to keep irrigation gear systems functioning properly. Gearboxes and other mechanical components require periodic checks, lubrication, and potential repairs, which can add to maintenance costs and downtime.

- Complexity: The complexity of irrigation gear systems can pose challenges for farmers who are not familiar with mechanical systems. Troubleshooting issues or making adjustments might require technical expertise.

- Dependence on Power: Many irrigation gear systems rely on electricity to operate, which can be a limitation in areas with unreliable power sources or during power outages.

- Environmental Impact: Depending on the energy source used, irrigation gear systems can have an environmental impact, especially if they are powered by non-renewable resources.

- Site Limitations: The suitability of irrigation gear systems depends on the layout and terrain of the field. Steep slopes, rocky terrain, or irregular field shapes might limit the effectiveness of these systems.

Despite these limitations, proper planning, maintenance, and operational considerations can help mitigate these challenges, allowing farmers to harness the benefits of irrigation gear systems while addressing their drawbacks.

Function of Irrigation Gearboxes in Agricultural Systems

An irrigation gearbox is a specialized component used in agricultural irrigation systems to control the movement of water for efficient irrigation. It plays a crucial role in distributing water to crops and fields effectively:

1. Water Flow Control: Irrigation gearboxes are designed to control the flow of water from the water source to the irrigation pipes or channels. They regulate the amount of water released and the direction in which it flows, ensuring even distribution across the entire field.

2. Valve Operation: Many irrigation systems use valves to manage water flow. Irrigation gearboxes are often integrated with these valves to open, close, or adjust them based on the irrigation schedule. The gearbox's rotational motion is translated into the linear motion needed to operate the valve mechanisms.

3. Timing and Scheduling: Some irrigation gearboxes are equipped with timers or sensors that allow for automated irrigation scheduling. The gearbox can be programmed to open or close valves at specific times, ensuring that crops receive water when needed.

4. Precision and Control: Irrigation gearboxes provide precise control over the water distribution process. This control is essential for preventing over- or under-watering, which can negatively impact crop health and yield. Proper water distribution also helps conserve water resources.

5. Adaptation to Terrain: Agricultural fields often have varying terrain and elevation changes. Irrigation gearboxes can be adjusted to accommodate different field layouts and slopes, ensuring that water reaches all areas evenly.

6. Integration with Pump Systems: In some cases, irrigation gearboxes are connected to pump systems that supply water from a water source such as a well or reservoir. The gearbox ensures that the pump operates efficiently, maintaining consistent water pressure and flow rates.

7. Maintenance and Durability: Irrigation gearboxes are designed to withstand the outdoor and agricultural environment. They are often constructed with durable materials and sealed to prevent water and debris ingress. Regular maintenance is required to ensure smooth operation and longevity.

Overall, irrigation gearboxes are essential components in agricultural irrigation systems. They enable precise control over water distribution, improve water efficiency, and contribute to the overall health and yield of crops by ensuring proper hydration.

editor by CX 2024-03-14

China Best Sales Worm Wafer Resilient Soft Seal Resilient Seat Ductile Iron Cast Iron Water Seal Butterfly Gate Valve Gearbox for Irrigation supplier

Product Description

Worm Wafer Resilient soft seal resilient seat ductile iron cast iron water seal butterfly gate valve gearbox for Irrigation

Overview

Hand operated worm gearbox with stainless steel housing and hand wheel.

For use with CHINAMFG stainless steel body butterfly valves.

Function

To provide hand wheel operation.

Sizing

Based on valve torque.

Suits 2″ to 6″ stainless body butterfly valves

Description

These hand operated gearboxes have a stainless steel housing and hand wheel and are an ideal partner for our range of stainless steel butterfly valves.

Related Products

Company Profile

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Optimizing Performance with Gear Ratios in Irrigation Gearboxes

Gear ratios play a crucial role in optimizing the performance of irrigation gearboxes by allowing precise control over the speed and torque output of the gearbox. Here's how gear ratios contribute to performance:

- Torque Multiplication: In irrigation systems, different tasks require varying levels of torque. By using gear ratios, the gearbox can multiply the torque from the input source, enabling the equipment to handle heavy loads such as moving large irrigation arms or distributing water through long pipes.

- Speed Reduction: In some cases, the output speed of the gearbox needs to be reduced to match the requirements of the irrigation equipment. Gear ratios enable the gearbox to slow down the rotational speed while maintaining sufficient torque, ensuring precise and controlled movement.

- Speed Increase: Conversely, gear ratios can also be used to increase the output speed of the gearbox, allowing faster movement of certain irrigation components like pivots or linear systems. This is particularly useful for covering larger areas efficiently.

- Precision Control: Gear ratios offer fine-tuning capabilities for controlling the movement of irrigation equipment. The ability to select the appropriate gear ratio ensures that the equipment moves at the desired speed, making it easier to achieve uniform water distribution and coverage.

By carefully choosing the right gear ratio for the specific irrigation task, operators can optimize the performance of their irrigation gearboxes, enhance water distribution efficiency, and ultimately contribute to successful and sustainable agricultural practices.

Ensuring Durability of Irrigation Gearboxes in Outdoor Environments

Manufacturers take several measures to ensure the durability of irrigation gearboxes in outdoor environments:

- Weather-Resistant Materials: Manufacturers use materials that are resistant to outdoor conditions, such as corrosion-resistant alloys and coatings to protect against moisture, UV radiation, and other environmental factors.

- Sealing and Enclosures: Irrigation gearboxes are often equipped with sealed enclosures to prevent dust, dirt, and water from entering the gearbox housing. This helps to maintain smooth operation and prevents damage to internal components.

- Gasket and O-Ring Seals: Gaskets and O-ring seals are used to create a tight seal between different components, preventing water and contaminants from entering critical areas.

- IP Ratings: Manufacturers design irrigation gearboxes with specific Ingress Protection (IP) ratings that indicate their resistance to water and dust. Higher IP ratings indicate better protection against outdoor elements.

- Proper Lubrication: Lubrication is crucial for preventing corrosion and ensuring smooth gear operation. Manufacturers select lubricants suitable for outdoor conditions and provide recommendations for regular maintenance.

- Robust Design: Gearboxes are designed to withstand the mechanical stresses associated with irrigation systems. Reinforced housing, high-quality bearings, and precision manufacturing contribute to their durability.

- Testing and Certification: Manufacturers subject irrigation gearboxes to rigorous testing under simulated outdoor conditions to ensure their performance and durability. They might also obtain certifications that verify the gearboxes' suitability for outdoor use.

These measures collectively contribute to the longevity and reliability of irrigation gearboxes in the challenging and variable conditions of outdoor agricultural environments.

Variations in Irrigation Gearbox Designs for Specific Irrigation Methods

Irrigation gearbox designs can vary based on the specific irrigation methods they are intended to be used with. Different irrigation techniques require different gearboxes to optimize water distribution. Here are some examples of variations in irrigation gearbox designs:

- Pivot Irrigation: Pivot irrigation systems use linear move or center pivot systems to distribute water in a circular pattern. Gearboxes for pivot irrigation often have a high degree of angular adjustability to accommodate the circular motion. They may also feature specialized seals and coatings to withstand exposure to water and environmental factors.

- Linear Irrigation: Linear irrigation involves moving the water distribution equipment along a straight line. Gearboxes for linear irrigation systems need to provide smooth and precise linear motion. They may incorporate linear actuators or guides to ensure accurate movement.

- Drip Irrigation: Drip irrigation delivers water directly to the plant root zone. Gearboxes for drip irrigation may be part of valve control systems that regulate the water flow to individual drip lines. These gearboxes need to be compact and efficient in controlling the flow rate.

- Sprinkler Irrigation: Sprinkler systems disperse water over the cultivated area in a spray pattern. Gearboxes for sprinkler irrigation may be used in the rotating heads of sprinklers. They need to provide reliable rotation and positioning for even water coverage.

- Subsurface Irrigation: Subsurface irrigation delivers water below the soil surface. Gearboxes for subsurface irrigation may be used in valve systems controlling the water release from underground pipes. They require durability and resistance to soil and moisture.

These variations in irrigation gearbox designs reflect the diverse needs of different irrigation methods. Customized gearbox designs help ensure efficient and effective water distribution for various agricultural and landscaping applications.

editor by CX 2024-02-16

China Custom Driveline Gearbox of Irrigation System differential gearbox

Product Description

SC Transmission Driveline Gearbox Of Irrigation System

Product Description

|

725 Series Gearbox: Models Include: |

| 730 Series Gearbox: Application; Heavy Duty Final drive wheel boxes with 2 1/2" output shaft for Longer spans, Larger wheels, and heavier towers on all electric drive and Hydraulic powered Center CHINAMFG and lateral/linear move Systems

Models Include: |

| 740 and 745 Series Gearbox: Application: Ultimate Duty Final drive wheel boxes with larger bearings and available with 2 1/4" or 2 1/2" output shaft for Longer spans, Larger wheels, and heavier towers on all electric drive and Hydraulic powered Center CHINAMFG / lateral move Systems |

| 760 Series Gearbox Application: Larger diameter Bull Gear to provide 20% higher output torque on all electric drive and Hydraulic powered Center CHINAMFG / lateral move Systems

Models Include: |

| 760 Series Gearbox Application: Larger diameter Bull Gear to provide 20% higher output torque on all electric drive and Hydraulic powered Center CHINAMFG / lateral move Systems

Models Include: |

| 725 T-NT (Tow - Non Tow) Series Gearbox Application: Towable Final drive wheel box, provide the ability to disengage the worm gear and allows users of all electric drive and Hydraulic powered Center CHINAMFG Systems and lateral/linear move systems to move systems from 1 area to another

Models Include: |

| 740 T-NT (Tow - Non Tow) Series Gearbox Application: Towable Final drive wheel box, provide the ability to disengage the worm gear and allows users of all electric drive and Hydraulic powered Center CHINAMFG Systems and lateral/linear move systems to move systems from 1 area to another

Models Include: |

Detailed Photos

Company Profile

FAQ

Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Shunting |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Factors in Selecting the Right Irrigation Gearbox

Choosing the appropriate irrigation gearbox involves considering several key factors to ensure optimal performance and water distribution efficiency:

- Irrigation Method: Different irrigation methods (pivot, linear, drip, etc.) have specific gearbox requirements. The gearbox must match the motion and distribution pattern of the chosen method.

- Load Capacity: The gearbox should be able to handle the load imposed by the irrigation equipment, including the weight of pipes, hoses, and sprinklers.

- Adjustability: For pivot and linear irrigation, the gearbox should allow for precise adjustments to control the radius of coverage.

- Environmental Conditions: The gearbox should be designed to withstand exposure to water, moisture, dirt, and varying weather conditions.

- Speed and Torque: The gearbox's speed and torque specifications must match the requirements of the irrigation system's movement and water distribution needs.

- Durability: The gearbox should have a robust construction to ensure a long lifespan, even in challenging agricultural environments.

- Efficiency: An efficient gearbox minimizes energy consumption, contributing to overall system efficiency.

- Compatibility: The gearbox must be compatible with the other components of the irrigation system, including motors, control systems, and actuators.

- Maintenance: Easy access for maintenance and servicing is crucial to prevent downtime during critical watering periods.

- Cost: Balancing performance and cost is essential to ensure that the selected gearbox provides the best value for the investment.

By carefully evaluating these factors, farmers and agricultural professionals can choose the right irrigation gearbox that meets the specific needs of their irrigation system and contributes to efficient water distribution and crop growth.

Choosing Lubrication for Irrigation Gearboxes

When selecting the appropriate lubrication for irrigation gearboxes, several considerations come into play:

- Environmental Conditions: Consider the outdoor environment in which the gearbox operates. Factors like temperature variations, humidity, and exposure to dust and water play a role in choosing the right lubricant.

- Water Resistance: Since irrigation gearboxes are often exposed to water, it's crucial to select a lubricant that provides effective water resistance to prevent rust and corrosion.

- Extreme Temperatures: If the gearbox operates in extreme temperatures, the lubricant should have a wide temperature range to ensure proper viscosity and performance in both hot and cold conditions.

- Load and Torque: The load and torque requirements of the gearbox affect the choice of lubrication. Heavy loads and high torques might require lubricants with enhanced film strength and anti-wear properties.

- Compatibility: Ensure that the selected lubricant is compatible with the gearbox materials and seals to prevent any adverse reactions or degradation.

- Longevity: Choose a lubricant that offers long-lasting performance and doesn't break down quickly, especially in continuous operation scenarios.

- Sealing: The lubricant should work well with the gearbox's sealing system to prevent leaks and maintain the integrity of the lubrication film.

- Ease of Application: Consider the ease of applying the lubricant, especially during maintenance procedures. Lubricants that are easy to apply and distribute evenly contribute to efficient gearbox operation.

- Regulations: If the farming operation is subject to certain regulations or standards, ensure that the selected lubricant complies with these requirements.

By carefully considering these factors, farmers and equipment operators can choose the appropriate lubrication for irrigation gearboxes, ensuring smooth and reliable operation in agricultural settings.

Function of Irrigation Gearboxes in Agricultural Systems

An irrigation gearbox is a specialized component used in agricultural irrigation systems to control the movement of water for efficient irrigation. It plays a crucial role in distributing water to crops and fields effectively:

1. Water Flow Control: Irrigation gearboxes are designed to control the flow of water from the water source to the irrigation pipes or channels. They regulate the amount of water released and the direction in which it flows, ensuring even distribution across the entire field.

2. Valve Operation: Many irrigation systems use valves to manage water flow. Irrigation gearboxes are often integrated with these valves to open, close, or adjust them based on the irrigation schedule. The gearbox's rotational motion is translated into the linear motion needed to operate the valve mechanisms.

3. Timing and Scheduling: Some irrigation gearboxes are equipped with timers or sensors that allow for automated irrigation scheduling. The gearbox can be programmed to open or close valves at specific times, ensuring that crops receive water when needed.

4. Precision and Control: Irrigation gearboxes provide precise control over the water distribution process. This control is essential for preventing over- or under-watering, which can negatively impact crop health and yield. Proper water distribution also helps conserve water resources.

5. Adaptation to Terrain: Agricultural fields often have varying terrain and elevation changes. Irrigation gearboxes can be adjusted to accommodate different field layouts and slopes, ensuring that water reaches all areas evenly.

6. Integration with Pump Systems: In some cases, irrigation gearboxes are connected to pump systems that supply water from a water source such as a well or reservoir. The gearbox ensures that the pump operates efficiently, maintaining consistent water pressure and flow rates.

7. Maintenance and Durability: Irrigation gearboxes are designed to withstand the outdoor and agricultural environment. They are often constructed with durable materials and sealed to prevent water and debris ingress. Regular maintenance is required to ensure smooth operation and longevity.

Overall, irrigation gearboxes are essential components in agricultural irrigation systems. They enable precise control over water distribution, improve water efficiency, and contribute to the overall health and yield of crops by ensuring proper hydration.

editor by CX 2024-01-31

China OEM Compact Planetary Gearbox for Agricultural Irrigation automatic gearbox

Product Description

Product Description

Product Parameters

| Parameters | Unit | Level | Reduction Ratio | Flange Size Specification | |||||

| 070 | 090 | 115 | 155 | 205 | 235 | ||||

| Rated output torque T2n | N.m | 1 | 3 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 5 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 7 | 35 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 35 | 120 | 260 | 500 | 1000 | 1600 | |||

| 10 | 23 | 48 | 140 | 370 | 520 | 1220 | |||

| 2 | 12 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 15 | 55 | 130 | 208 | 342 | 588 | 1140 | |||

| 20 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 28 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 35 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 40 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 50 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 70 | 35 | 140 | 310 | 550 | 1100 | 1800 | |||

| 100 | 23 | 48 | 140 | 370 | 520 | 1220 | |||

| 3 | 120 | 60 | 160 | 330 | 650 | 1200 | 2000 | ||

| 150 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 200 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 250 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 280 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 350 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 400 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 500 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 700 | 35 | 140 | 310 | 550 | 1100 | 1800 | |||

| 1000 | 23 | 48 | 140 | 370 | 520 | 1220 | |||

| Maximum output torque T2b | N.m | 1,2,3 | 3~1000 | 3Times of Rated Output Torque | |||||

| Rated input speed N1n | rpm | 1,2,3 | 3~1000 | 5000 | 3000 | 3000 | 3000 | 3000 | 2000 |

| Maximum input speed N1b | rpm | 1,2,3 | 3~1000 | 10000 | 6000 | 6000 | 6000 | 6000 | 4000 |

| Ultra Precision Backlash PS | arcmin | 1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| arcmin | 2 | 12~100 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |

| arcmin | 3 | 120~1000 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| High Precision Backlash P0 | arcmin | 1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| arcmin | 2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| arcmin | 3 | 120~1000 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |

| Precision Backlash P1 | arcmin | 1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| arcmin | 2 | 12~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| arcmin | 3 | 12~1000 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | |

| Standard Backlash P2 | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| arcmin | 2 | 12~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |

| arcmin | 3 | 120~1000 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 | |

| Torsional Rigidity | Nm/arcmin | 1,2,3 | 3~1000 | 3.5 | 10.5 | 20 | 39 | 115 | 180 |

| Allowable radial force F2rb2 | N | 1,2,3 | 3~1000 | 1100 | 2200 | 5571 | 7610 | 10900 | 24000 |

| Allowable axial force F2ab2 | N | 1,2,3 | 3~1000 | 630 | 1230 | 2550 | 3780 | 5875 | 11200 |

| Moment of Inertia J1 | kg.cm2 | 1 | 3~10 | 0.2 | 1.2 | 2 | 7.2 | 25 | 65 |

| 2 | 12~100 | 0.08 | 0.18 | 0.7 | 1.7 | 7.9 | 14 | ||

| 3 | 120~1000 | 0.03 | 0.01 | 0.04 | 0.09 | 0.21 | 0.82 | ||

| Service Life | hr | 1,2,3 | 3~1000 | 20000 | |||||

| Efficiency η | % | 1 | 3~10 | 97% | |||||

| 2 | 12~100 | 94% | |||||||

| 3 | 120~1000 | 91% | |||||||

| Noise Level | dB | 1,2,3 | 3~1000 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

| Operating Temperature | ºC | 1,2,3 | 3~1000 | -10~+90 | |||||

| Protection Class | IP | 1,2,3 | 3~1000 | IP65 | |||||

| Weights | kg | 1 | 3~10 | 1.3 | 3.7 | 7.8 | 14.5 | 29 | 48 |

| 2 | 12~100 | 1.9 | 4.1 | 9 | 17.5 | 33 | 60 | ||

| 3 | 120~1000 | 2.3 | 4.8 | 12 | 22 | 37 | 72 | ||

FAQ

Q: How to select a gearbox?

A: Firstly, determine the torque and speed requirements for your application. Consider the load characteristics, operating environment, and duty cycle. Then, choose the appropriate gearbox type, such as planetary, worm, or helical, based on the specific needs of your system. Ensure compatibility with the motor and other mechanical components in your setup. Lastly, consider factors like efficiency, backlash, and size to make an informed selection.

Q: What type of motor can be paired with a gearbox?

A: Gearboxes can be paired with various types of motors, including servo motors, stepper motors, and brushed or brushless DC motors. The choice depends on the specific application requirements, such as speed, torque, and precision. Ensure compatibility between the gearbox and motor specifications for seamless integration.

Q: Does a gearbox require maintenance, and how is it maintained?

A: Gearboxes typically require minimal maintenance. Regularly check for signs of wear, lubricate as per the manufacturer's recommendations, and replace lubricants at specified intervals. Performing routine inspections can help identify issues early and extend the lifespan of the gearbox.

Q: What is the lifespan of a gearbox?

A: The lifespan of a gearbox depends on factors such as load conditions, operating environment, and maintenance practices. A well-maintained gearbox can last for several years. Regularly monitor its condition and address any issues promptly to ensure a longer operational life.

Q: What is the slowest speed a gearbox can achieve?

A: Gearboxes are capable of achieving very slow speeds, depending on their design and gear ratio. Some gearboxes are specifically designed for low-speed applications, and the choice should align with the specific speed requirements of your system.

Q: What is the maximum reduction ratio of a gearbox?

A: The maximum reduction ratio of a gearbox depends on its design and configuration. Gearboxes can achieve various reduction ratios, and it's important to choose 1 that meets the torque and speed requirements of your application. Consult the gearbox specifications or contact the manufacturer for detailed information on available reduction ratios.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Agricultural Machinery, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Handling Different Soil and Terrain with Irrigation Gearboxes

Irrigation gearboxes are designed to effectively handle various types of soil and terrain, ensuring reliable and efficient water distribution. Here's how they adapt to different conditions:

- Variable Torque: Different soil types require varying levels of force to move irrigation equipment. Irrigation gearboxes can adjust their torque output to accommodate softer or harder soil, ensuring the equipment can move smoothly even in challenging conditions.

- Traction Control: In hilly or uneven terrains, traction can be an issue. Irrigation gearboxes are equipped with features that enhance traction, such as slip-resistant surfaces or adjustable torque settings. This prevents slippage and maintains consistent movement on different terrains.

- Controlled Speed: Different terrains may demand different speeds to ensure uniform water distribution. Irrigation gearboxes allow operators to adjust the speed according to the terrain, preventing excessive water application in certain areas and ensuring optimal coverage.

- Adaptable Design: Some irrigation gearboxes have adaptable designs, allowing for easy customization based on the specific terrain and irrigation method. This ensures that the equipment operates efficiently and effectively, regardless of the challenges presented by the terrain.

By offering versatility and adaptability, irrigation gearboxes enable farmers to navigate and irrigate different types of soil and terrains with precision, ensuring consistent water distribution and optimal crop growth.

Disadvantages and Limitations of Using Irrigation Gear Systems

While irrigation gear systems offer numerous benefits, they also come with some disadvantages and limitations:

- Cost: Irrigation gear systems can be relatively expensive to install and maintain, especially when compared to manual irrigation methods. The initial investment includes the cost of gearboxes, motors, pumps, and other associated components.

- Maintenance: Regular maintenance is essential to keep irrigation gear systems functioning properly. Gearboxes and other mechanical components require periodic checks, lubrication, and potential repairs, which can add to maintenance costs and downtime.

- Complexity: The complexity of irrigation gear systems can pose challenges for farmers who are not familiar with mechanical systems. Troubleshooting issues or making adjustments might require technical expertise.

- Dependence on Power: Many irrigation gear systems rely on electricity to operate, which can be a limitation in areas with unreliable power sources or during power outages.

- Environmental Impact: Depending on the energy source used, irrigation gear systems can have an environmental impact, especially if they are powered by non-renewable resources.

- Site Limitations: The suitability of irrigation gear systems depends on the layout and terrain of the field. Steep slopes, rocky terrain, or irregular field shapes might limit the effectiveness of these systems.

Despite these limitations, proper planning, maintenance, and operational considerations can help mitigate these challenges, allowing farmers to harness the benefits of irrigation gear systems while addressing their drawbacks.

Benefits of Using an Irrigation Gearbox in Irrigation Systems

Irrigation gearboxes offer several advantages when integrated into irrigation systems for agricultural purposes:

1. Efficient Water Management: Irrigation gearboxes allow precise control over water flow rates, ensuring that crops receive the right amount of water. This efficiency prevents overwatering or underwatering and optimizes water usage.

2. Uniform Water Distribution: By regulating water flow, irrigation gearboxes ensure uniform water distribution across the field. This prevents uneven crop growth and provides consistent moisture to all plants.

3. Customized Irrigation: Modern irrigation gearboxes can be programmed with specific irrigation schedules based on crop needs, weather conditions, and soil moisture levels. This customization enhances water efficiency and crop health.

4. Adaptability to Terrain: Agricultural fields often have varying slopes and terrains. Irrigation gearboxes can be adjusted to accommodate these changes, allowing water to flow evenly and reach all areas of the field.

5. Water Conservation: Precise water distribution minimizes wastage, contributing to water conservation efforts. This is particularly important in regions where water resources are scarce.

6. Increased Crop Yields: Uniform water distribution and efficient moisture management promote healthy crop growth, resulting in higher yields and improved crop quality.

7. Prevention of Waterlogging: Irrigation gearboxes help prevent waterlogging by controlling water levels. This prevents root damage and soil compaction that can occur from excessive water accumulation.

8. Reduction in Labor: Automated irrigation systems equipped with irrigation gearboxes reduce the need for manual intervention. Farmers can set up automated watering schedules, saving time and labor.

9. Environmental Sustainability: Using irrigation gearboxes to optimize water usage aligns with sustainable farming practices and reduces the environmental impact of agriculture.

10. Improved Plant Health: Consistent and controlled water distribution enhances plant health, as it minimizes stress caused by inadequate or excessive watering.

11. Enhanced Crop Management: Irrigation gearboxes enable farmers to easily manage and adjust irrigation schedules, ensuring that crops receive water at optimal times for growth.

12. Return on Investment: While the initial investment may be incurred when installing irrigation systems with gearboxes, the long-term benefits, including increased yields and resource efficiency, often result in a positive return on investment.

Irrigation gearboxes play a pivotal role in modern agricultural practices by optimizing water distribution, enhancing crop productivity, and promoting sustainable irrigation methods.

editor by CX 2024-01-30

China high quality Agricultural Machinery Part Gear Box Worm Spray Center CZPT Irrigation Sprinklers Water Pump System Gearbox for Farm Greenhouse with Good quality

Product Description

Agricultural Machinery Part Gear Box Worm Spray Center CHINAMFG Irrigation Sprinklers Water Pump System Gearbox for Farm Greenhouse

Our Factory:

1. Shell: made of high rigidity fc-25 cast iron;

2. Gear: high purity alloy steel 20crmnt is used for quenching and tempering, carburizing, quenching and grinding;

3. Spindle: high purity alloy steel 40Cr quenching and tempering processing, with high hanging load capacity.

4. Bearing: equipped with tapered roller bearing with heavy load capacity;

5. Oil seal: imported double lip oil seal, with the ability of dust and oil leakage.

Product lubrication:

The use of proper lubricating oil for t spiral bevel gear commutator can give full play to the efficiency of the steering gear and improve its service life.

1. The initial wear period is 2 weeks or 100-200 hours. There may be a small amount of metal wear particles between them. Please clean the interior and replace it with new lubricating oil;

2. In case of long-term use, change the lubricating oil every half a year or 1000-2000 hours.

Technical parameters of T spiral bevel gear commutator:

It can be equipped with single horizontal axis, double horizontal axis, single vertical axis and double vertical axis 1:5, 1:5, 1:1, 1:5, 1:5, 1:1

Related products:

Application:

Company Profile:

Services

Also I would like to take this opportunity to give a brief introduction of our CHINAMFG company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, CHINAMFG , CHINAMFG

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

......

-Ø Our Company with over 12 year's history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

......

You also can check our website to know for more details, if you need our products catalogue, please contact with us. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Compatibility with Different Types of Irrigation Pumps

Irrigation gearboxes are designed to be versatile and compatible with various types of irrigation pumps. They can be used with:

- Centrifugal Pumps: These are commonly used for irrigation due to their efficiency and simplicity. Irrigation gearboxes can easily connect to the output shaft of centrifugal pumps, allowing them to convert rotational power to the desired movement for irrigation systems.

- Positive Displacement Pumps: These pumps provide a consistent flow rate and are often used for more precise irrigation applications. Irrigation gearboxes can be integrated to ensure precise control over the movement and speed of positive displacement pumps.

- Submersible Pumps: These pumps are often used in deep wells or reservoirs. While not directly connected to irrigation gearboxes, the gearbox can control the mechanisms that adjust the position of submersible pumps in wells or reservoirs, optimizing water intake.

- Diaphragm Pumps: Diaphragm pumps are commonly used for small-scale irrigation or drip systems. Irrigation gearboxes can regulate the movement of diaphragm pumps, controlling the amount of water released.

The adaptability of irrigation gearboxes makes them suitable for various irrigation pump types, allowing farmers and agricultural operators to efficiently manage water distribution and optimize irrigation practices.

Adaptability of Irrigation Gearboxes for Small and Large-Scale Farming

Irrigation gearboxes are designed with adaptability in mind, making them suitable for both small and large-scale farming:

- Modular Design: Many irrigation gearboxes have a modular design that allows for customization and scalability. Different gearbox sizes and configurations can be selected based on the scale of the farming operation.

- Multiple Ratios: Irrigation gearboxes often come with a range of gear ratios. This allows farmers to choose the appropriate gear ratio for their specific application, whether it's a small-scale garden or a large agricultural field.

- Compatibility: Manufacturers often provide a variety of mounting options and input/output configurations, making it easier to integrate irrigation gearboxes into different irrigation systems, regardless of scale.

- Efficiency and Precision: Regardless of scale, irrigation gearboxes provide efficient water distribution and precise control. This benefits both small gardens and large fields, ensuring water is distributed accurately to the plants' needs.

- Range of Applications: Irrigation gearboxes can be used for various irrigation methods, such as center pivot, linear, and drip irrigation. This versatility makes them suitable for different farming scales.

- Cost-Effectiveness: Manufacturers often offer a range of irrigation gearboxes with varying features and performance levels. Farmers can choose the gearbox that best meets their needs and budget.

- Ease of Maintenance: Many irrigation gearboxes are designed for easy maintenance, which is beneficial regardless of the farming scale. Simple maintenance procedures contribute to the longevity and reliability of the gearboxes.

Overall, the adaptability of irrigation gearboxes makes them a versatile solution for both small and large-scale farming operations, ensuring efficient and controlled water distribution to optimize crop growth.

Role of an Irrigation Gearbox in Pivot and Linear Irrigation

Irrigation gearboxes play a crucial role in both pivot and linear irrigation systems by facilitating the controlled movement of irrigation equipment and ensuring efficient water distribution:

Pivot Irrigation: In pivot irrigation systems, a central pivot point supports a rotating arm with sprinklers attached. Irrigation gearboxes are used to drive the pivot movement, allowing the arm to rotate around the pivot point. As the arm moves, the sprinklers distribute water over the field in a circular pattern. The irrigation gearbox controls the speed and direction of the pivot, ensuring uniform water coverage and preventing overwatering or underwatering in specific areas.

Linear Irrigation: Linear irrigation involves the movement of irrigation equipment along a straight line across the field. Irrigation gearboxes are used to drive the motion of the irrigation equipment, which can include sprinklers, drip lines, or other water distribution devices. The gearbox controls the speed and direction of the movement, ensuring that water is evenly distributed along the length of the field. This method is particularly useful for rectangular or elongated fields.

Both pivot and linear irrigation systems rely on irrigation gearboxes to regulate the movement of irrigation equipment, leading to efficient water distribution and optimized crop watering. The use of irrigation gearboxes enhances water management and contributes to the overall success of agricultural irrigation systems.

editor by CX 2024-01-29

China Custom CZPT 765UV Gearbox on Center CZPT Irrigation System with Best Sales

Product Description

UMC is the industry leader in gearbox technology. Over our 40 year history we have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. We continue to define and redefine industry standards for gearbox performance, quality, features and technology. Our gearboxes are purpose built to do the job. Never over-engineered.

UMC stands behind its products and is committed to manufacturing the best products for a global market.

740-U 50:1 Ratio

Designed for longer spans, larger wheels, and heavier towers.

Features and Benefits

- 2.25 inch output shaft

- 50:1 gear ratio

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

740-UV 52:1 Ratio

Designed for longer spans, larger wheels and heavier towers where an extended output shaft is required.

This gearbox has all the same capabilities, features and benefits that the standard 740 has with a few tweaks. The output shaft is extended, the gear ratio is 52:1 and the input shaft is made of ductile iron with a 25° pressure angle allowing this gearbox to be used on center CHINAMFG and lateral move/ linear systems that come standard with these specifications.

Features and Benefits

- 2.25 inch extended output shaft

- 52:1 gear ratio with 25° pressure angle

- Cartridge input and output seals

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- Universal mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Gearbox

Designed for corner systems and lateral move carts where an extended output shaft is required

Growers typically use UMC's 760-UV gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV final drive gearbox is our largest and most durable gearbox with an extended output shaft. It features a larger-diameter bull gear than the standard 740 series to handle 20% higher torque. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- 20% more torque capacity than the standard 740

- Bronze gear optional

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

TNT-2 Gearbox

Designed for applications where the irrigation system may need to be towed

This gearbox is the perfect solution for a towable irrigation system. Growers typically prefer this gearbox over a gearbox with a towable hub. Simply disengage the worm and tow your system to its working location, then re-engage the worm and you are ready to run. The CX coupler is the perfect compliment for the TNT-2 gearbox due to the ability to control coupler disengagement at the gearbox.

The UMC patented TNT-2 final drive gearbox is designed specifically for applications where a center CHINAMFG or lateral move/ linear irrigation system needs to be towed. The gearbox provides the ability to disengage the worm gear and allows users to move systems from 1 area to another without requiring a Towable Hub add on.

Features and Benefits

- 2.25″ output shaft

- 50:1 gear ratio

- Dual input seals with triple lip output seals

- Bronze gear optional

- Input shaft guard

- External seal protectors for input and output seals

- Top oil fill plug

- 11-Bolt mounting pattern

- Full cycle expansion chamber with stainless steel cover

- Filled with extreme pressure worm gear oil

- Steel output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

760-UV Bronze Gearbox

Designed for the most extreme conditions where an extended output shaft is required.

Growers typically use The UMC 760-UV bronze gearbox for the most extreme applications where an extended output shaft is required. The gearbox is designed for higher annual hours of operation while handling the heavy loads experienced on corner systems and lateral move carts as well as the most extreme field conditions where wheel rutting is prominent, soil is heavy, and tower weights are higher.

The UMC 760-UV Bronze final drive gearbox is our largest and most durable gearbox with an extended output shaft designed for the most extreme growing conditions. It features a high strength aluminum bronze bull gear and a heat treated steel worm gear giving it a much higher load capacity than the standard 760-UV. Additionally, this gear combination greatly reduces gear wear, extending the useful life of the gearbox. It also features a 2.5″ output shaft to accommodate more overhung load. It is designed for use on center pivots, corners, lateral move/ linear irrigation systems and carts where a 52:1 gear ratio and extended output shaft are standard specifications.

Features and Benefits

- 2.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal design

- Bronze Gear

- Heat Treated Steel Worm Gear

- Larger input bearings

- Input shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting pattern

- Full cycle expansion chamber with aluminum cover

- Filled with extreme pressure worm gear oil

- Steel output shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Dual ended input shaft

- Also Available Assembled in the USA

CHINAMFG is the industry leader in gearbox technology. Over 37 year history they have introduced many industry changing gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and more. CHINAMFG continue to define and redefine industry standards for gearbox performance, quality, features and technology. CHINAMFG gearboxes are purpose built to do the job. Never over-engineered.UMC stands behind its products and is committed to manufacturing the best products for a global market.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Agricultural |

|---|---|

| Function: | Speed Reduction |

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Material: | Cast Iron |