Product Description

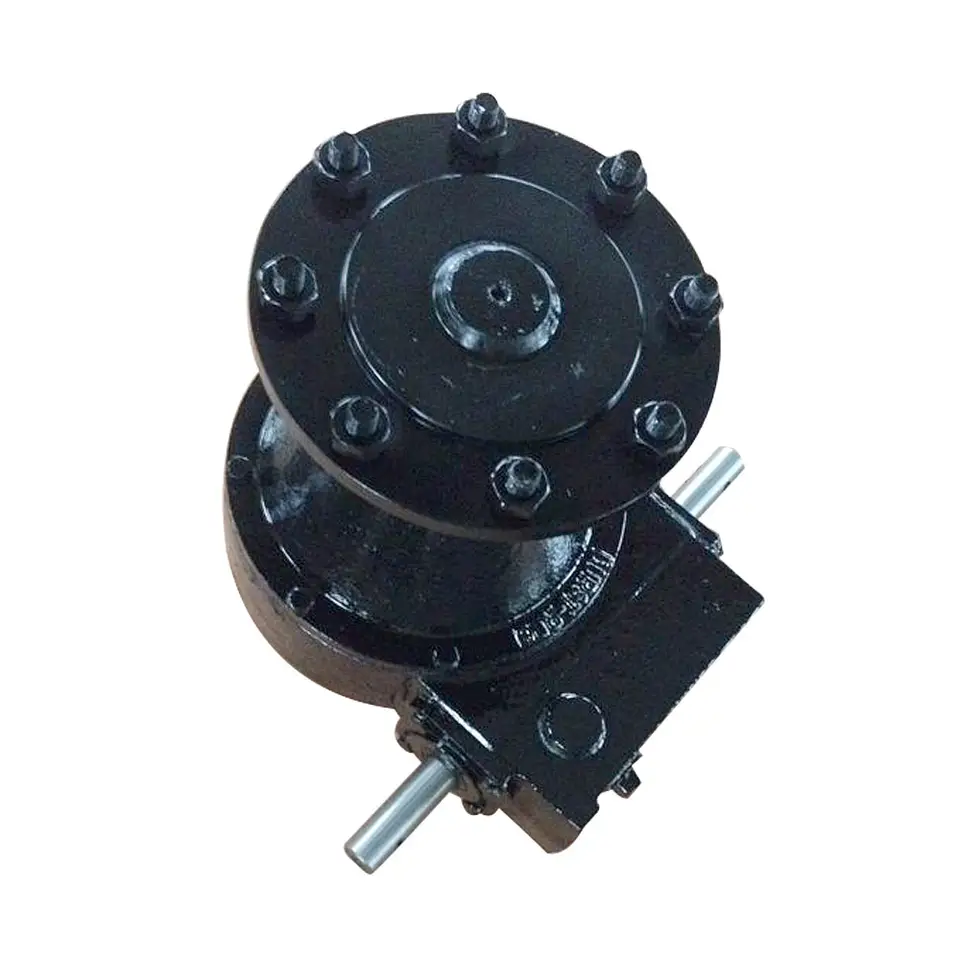

Worm Wafer Resilient soft seal resilient seat ductile iron cast iron water seal butterfly gate valve gearbox for Irrigation

Overview

Hand operated worm gearbox with stainless steel housing and hand wheel.

For use with CHINAMFG stainless steel body butterfly valves.

Function

To provide hand wheel operation.

Sizing

Based on valve torque.

Suits 2″ to 6″ stainless body butterfly valves

Description

These hand operated gearboxes have a stainless steel housing and hand wheel and are an ideal partner for our range of stainless steel butterfly valves.

Related Products

Company Profile

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Optimizing Performance with Gear Ratios in Irrigation Gearboxes

Gear ratios play a crucial role in optimizing the performance of irrigation gearboxes by allowing precise control over the speed and torque output of the gearbox. Here's how gear ratios contribute to performance:

- Torque Multiplication: In irrigation systems, different tasks require varying levels of torque. By using gear ratios, the gearbox can multiply the torque from the input source, enabling the equipment to handle heavy loads such as moving large irrigation arms or distributing water through long pipes.

- Speed Reduction: In some cases, the output speed of the gearbox needs to be reduced to match the requirements of the irrigation equipment. Gear ratios enable the gearbox to slow down the rotational speed while maintaining sufficient torque, ensuring precise and controlled movement.

- Speed Increase: Conversely, gear ratios can also be used to increase the output speed of the gearbox, allowing faster movement of certain irrigation components like pivots or linear systems. This is particularly useful for covering larger areas efficiently.

- Precision Control: Gear ratios offer fine-tuning capabilities for controlling the movement of irrigation equipment. The ability to select the appropriate gear ratio ensures that the equipment moves at the desired speed, making it easier to achieve uniform water distribution and coverage.

By carefully choosing the right gear ratio for the specific irrigation task, operators can optimize the performance of their irrigation gearboxes, enhance water distribution efficiency, and ultimately contribute to successful and sustainable agricultural practices.

Ensuring Durability of Irrigation Gearboxes in Outdoor Environments

Manufacturers take several measures to ensure the durability of irrigation gearboxes in outdoor environments:

- Weather-Resistant Materials: Manufacturers use materials that are resistant to outdoor conditions, such as corrosion-resistant alloys and coatings to protect against moisture, UV radiation, and other environmental factors.

- Sealing and Enclosures: Irrigation gearboxes are often equipped with sealed enclosures to prevent dust, dirt, and water from entering the gearbox housing. This helps to maintain smooth operation and prevents damage to internal components.

- Gasket and O-Ring Seals: Gaskets and O-ring seals are used to create a tight seal between different components, preventing water and contaminants from entering critical areas.

- IP Ratings: Manufacturers design irrigation gearboxes with specific Ingress Protection (IP) ratings that indicate their resistance to water and dust. Higher IP ratings indicate better protection against outdoor elements.

- Proper Lubrication: Lubrication is crucial for preventing corrosion and ensuring smooth gear operation. Manufacturers select lubricants suitable for outdoor conditions and provide recommendations for regular maintenance.

- Robust Design: Gearboxes are designed to withstand the mechanical stresses associated with irrigation systems. Reinforced housing, high-quality bearings, and precision manufacturing contribute to their durability.

- Testing and Certification: Manufacturers subject irrigation gearboxes to rigorous testing under simulated outdoor conditions to ensure their performance and durability. They might also obtain certifications that verify the gearboxes' suitability for outdoor use.

These measures collectively contribute to the longevity and reliability of irrigation gearboxes in the challenging and variable conditions of outdoor agricultural environments.

Variations in Irrigation Gearbox Designs for Specific Irrigation Methods

Irrigation gearbox designs can vary based on the specific irrigation methods they are intended to be used with. Different irrigation techniques require different gearboxes to optimize water distribution. Here are some examples of variations in irrigation gearbox designs:

- Pivot Irrigation: Pivot irrigation systems use linear move or center pivot systems to distribute water in a circular pattern. Gearboxes for pivot irrigation often have a high degree of angular adjustability to accommodate the circular motion. They may also feature specialized seals and coatings to withstand exposure to water and environmental factors.

- Linear Irrigation: Linear irrigation involves moving the water distribution equipment along a straight line. Gearboxes for linear irrigation systems need to provide smooth and precise linear motion. They may incorporate linear actuators or guides to ensure accurate movement.

- Drip Irrigation: Drip irrigation delivers water directly to the plant root zone. Gearboxes for drip irrigation may be part of valve control systems that regulate the water flow to individual drip lines. These gearboxes need to be compact and efficient in controlling the flow rate.

- Sprinkler Irrigation: Sprinkler systems disperse water over the cultivated area in a spray pattern. Gearboxes for sprinkler irrigation may be used in the rotating heads of sprinklers. They need to provide reliable rotation and positioning for even water coverage.

- Subsurface Irrigation: Subsurface irrigation delivers water below the soil surface. Gearboxes for subsurface irrigation may be used in valve systems controlling the water release from underground pipes. They require durability and resistance to soil and moisture.

These variations in irrigation gearbox designs reflect the diverse needs of different irrigation methods. Customized gearbox designs help ensure efficient and effective water distribution for various agricultural and landscaping applications.

editor by CX 2024-02-16

China wholesaler Xhw35LPG2 Worm Gearbox for Valve with Good quality

Product Description

Model: XHW35LPG2 worm gearbox for valve

Double stage, vertical

Application

XHW part turn worm gearboxes are applied to dampers, ball valves, butterfly valves and also other 90° quarter turn valves.XHW part turn worm gear operator has variety models of hand wheel for optional.

Operating Environment

XHW part turn worm gearboxes are with good mechanical quality and steady operating performance which apply to deal with variety climate and temperature. We strive to develop RHW part turn worm gear operators to meet higher demands.

Enclosure: IP67

Working Temperature: From -20ºC to 120ºC( -4ºF to 248ºF)

Painting: Silver grey (Customization)

Introduction

XHW series Part-turn Gearboxes use worm and worm wheel revolute pairs, with high performance needle roller bearing assembled on both ends of the worm shaft. It ensures the thrust requirement during rotation. It's in high mechanical efficiency withstands big torque, small size with compact design, and it's also easy to operate and has reliable self-locking function.

Characters

1.Precision casting ductile iron housing

2.Optional output torque, range up to 32000Nm

3.High efficient needle roller bearing

4.High strength steel input shaft

5.Stroke 0°- 90°( ±5°)

6.Compact structure

7.Grease filled for longer life

8.Adjustable stopper (±5°)

9.Good seal

Connect with valve

The flange connecting to valve is according to ENISO5210 or DIN3210(Customization)

Main Products

Worm gearbox, bevel gearbox, valve gear box, worm gear operator, worm gear actuator, valve worm gear, valve gear operator, valve gear actuator, valve actuator

Gear Operator, Valve Gearbox, Worm Gearbox, Gearbox, Speed Reducer, Part-turn Worm Gearbox, Worm Gearbox Supplier, High Quality Worm Gearbox, Gearbox manufacturer

(XHW35-PG4S)

| Application: | Industry |

|---|---|

| Type: | Worm and Wormwheel |

| Painting: | Silver Grey or Customization |

| Manipulate Way: | Manual Operation |

| Material: | Cast Iron |

| Working Temperature: | -20 to 120 Degrees Celsius |

| Customization: |

Available

| Customized Request |

|---|

Calculating Gear Ratio in a Worm Reducer

The gear ratio in a worm reducer is determined by the number of teeth on the worm wheel (also known as the worm gear) and the number of threads on the worm shaft. The gear ratio formula for a worm reducer is:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Shaft

For example, if the worm wheel has 60 teeth and the worm shaft has a single thread, the gear ratio would be 60:1.

It's important to note that worm reducers have an inherent self-locking property due to the angle of the worm threads. As a result, the gear ratio also affects the mechanical advantage and the system's ability to resist backdriving.

When calculating the gear ratio, ensure that the worm reducer is properly designed and that the gear ratio aligns with the desired mechanical characteristics for your application. Additionally, consider factors such as efficiency, load capacity, and speed limitations when selecting a gear ratio for a worm reducer.

How to Calculate the Efficiency of a Worm Gearbox

Calculating the efficiency of a worm gearbox involves determining the ratio of output power to input power. Efficiency is a measure of how well the gearbox converts input power into useful output power without losses. Here's how to calculate it:

- Step 1: Measure Input Power: Measure the input power (Pin) using a power meter or other suitable measuring equipment.

- Step 2: Measure Output Power: Measure the output power (Pout) that the gearbox is delivering to the load.

- Step 3: Calculate Efficiency: Calculate the efficiency (η) using the formula: Efficiency (η) = (Output Power / Input Power) * 100%

For example, if the input power is 1000 watts and the output power is 850 watts, the efficiency would be (850 / 1000) * 100% = 85%.

It's important to note that efficiencies can vary based on factors such as gear design, lubrication, wear, and load conditions. The calculated efficiency provides insight into how effectively the gearbox is converting power, but it's always a good practice to refer to manufacturer specifications for gearbox efficiency ratings.

Preventing Backlash in a Worm Gearbox

Backlash in a worm gearbox can lead to reduced accuracy, positioning errors, and decreased overall efficiency. Here are steps to prevent or minimize backlash:

- High-Quality Components: Use high-quality worm gears and worm wheels with tight manufacturing tolerances. Precision components will help reduce backlash.

- Proper Meshing: Ensure the worm gear and worm wheel are properly aligned and meshed. Improper meshing can lead to increased backlash.

- Preload: Applying a small amount of preload to the worm gear can help reduce backlash. However, excessive preload can increase friction and wear.

- Anti-Backlash Mechanisms: Consider using anti-backlash mechanisms, such as spring-loaded systems or adjustable shims, to compensate for any inherent backlash.

- Lubrication: Proper lubrication can reduce friction and play a role in minimizing backlash. Use a lubricant that provides good film strength and reduces wear.

- Maintenance: Regularly inspect and maintain the gearbox to identify and address any changes in backlash over time.

It's important to strike a balance between reducing backlash and maintaining smooth operation. Consulting with gearbox experts and following manufacturer guidelines will help you optimize your worm gearbox's performance while minimizing backlash.

editor by CX 2023-09-18

China Hot selling CE /ISO Featured Products Gear Box with Pneumatic Actuator for Valve Control gearbox and motor

Product Description

HangZhou St.CHINAMFG Pneumatic Valve Actuators Maker Co.,Ltd

The Professional Pneumatic Valve Actuator Marker since 1994

Address: No.48, Xihong Road, New District, HangZhou City,China

| Application: | Motor, Motorcycle, Machinery |

|---|---|

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Type: | Worm Gear Box |

| Customization: |

Available

| Customized Request |

|---|

Can a Worm Gearbox be Used for High-Speed Applications?

Worm gearboxes are generally not recommended for high-speed applications due to their inherent design characteristics. Here's why:

- Efficiency: Worm gearboxes tend to have lower efficiency compared to other gearbox types, which means they can generate more heat and experience more energy loss at high speeds.

- Heat Generation: The sliding contact between the worm and worm wheel in a worm gearbox can lead to significant friction and heat generation, especially at high speeds. This heat can cause thermal expansion, affecting the gearbox's performance and longevity.

- Wear and Noise: High speeds can exacerbate wear and noise issues in worm gearboxes. Increased friction and wear can lead to faster degradation of components, resulting in reduced lifespan and increased maintenance needs.

- Backlash: Worm gearboxes may have higher backlash compared to other gearbox types, which can impact precision and accuracy in high-speed applications.

While worm gearboxes are more commonly used in applications requiring high torque and moderate speeds, they may not be the best choice for high-speed scenarios. If high-speed operation is a requirement, other gearbox types such as helical, spur, or planetary gearboxes are often better suited due to their higher efficiency, lower heat generation, and reduced wear at elevated speeds.

Does a Worm Reducer Require Frequent Maintenance?

Worm reducers generally require less frequent maintenance compared to some other types of gearboxes due to their design and operating characteristics. However, maintenance is still essential to ensure optimal performance and longevity. Here are some key points to consider:

- Lubrication: Proper lubrication is crucial for worm gearboxes. Regularly check the lubricant level and quality to prevent wear and overheating. Lubricant should be changed as recommended by the manufacturer.

- Inspections: Periodically inspect the gearbox for signs of wear, damage, or oil leaks. Check for any unusual noises, vibrations, or changes in performance that could indicate a problem.

- Tightening and Alignment: Check and tighten any loose fasteners and ensure that the gearbox is properly aligned. Misalignment can lead to increased wear and reduced efficiency.

- Seal Maintenance: Inspect and maintain seals to prevent oil leakage and contaminants from entering the gearbox.

- Cleaning: Keep the gearbox clean from debris and contaminants that could affect its performance. Regular cleaning can prevent premature wear and damage.

- Load and Speed: Ensure that the gearbox is operating within its rated load and speed limits. Exceeding these limits can lead to accelerated wear and potential failure.

- Environmental Conditions: Consider the operating environment of the gearbox. Extreme temperatures, humidity, and other factors can impact the gearbox's performance and longevity.

While worm gearboxes are known for their durability and self-locking feature, neglecting maintenance can lead to premature wear, reduced efficiency, and potential breakdowns. Following the manufacturer's recommendations for maintenance intervals and procedures is essential to keep the worm reducer in optimal condition.

What Industries Commonly Use Worm Reducers?

Worm reducers are versatile mechanical components that find applications in various industries due to their unique advantages and capabilities. Some of the industries that commonly use worm reducers include:

- Material Handling: Worm reducers are widely used in material handling equipment such as conveyors, bucket elevators, and cranes to control movement and manage heavy loads.

- Automotive: They are utilized in automotive manufacturing processes, assembly lines, and vehicle positioning systems.

- Food and Beverage: Worm reducers are used in food processing and packaging machinery where hygiene and cleanliness are crucial.

- Agriculture: Agricultural equipment like irrigation systems and tractors use worm reducers for controlling rotational motion.

- Mining and Construction: Heavy-duty applications in mining equipment, excavators, and construction machinery benefit from the torque multiplication provided by worm reducers.

- Energy: Wind turbines and solar tracking systems use worm reducers to convert low-speed, high-torque motion into rotational energy.

- Textile: Textile machinery employs worm reducers for controlling speed and tension in weaving and spinning operations.

- Packaging: Packaging equipment relies on worm reducers for precise movement and positioning of packaging materials.

- Medical: Medical devices and equipment often utilize worm reducers for their accuracy and controlled motion.

- Printing: Printing machines use worm reducers to regulate paper feed and ensure consistent printing quality.

Worm reducers' ability to provide high torque output, compact design, and self-locking characteristics makes them suitable for applications requiring reliable and controlled motion across various industries.

editor by CX 2023-09-18

China manufacturer Yj-1s-L Series Part-Turn Manual Valve Worm Gearbox for Butterfly Ball Valves differential gearbox

Product Description

Product Description

YJ-1S-L series Part-turn worm gearboxes suitable for Ball Valves, Butterfly Valves, Plug Valves,etc. Handwheel can choose according to your requirements.

YJ-1S-L series part-turn worm gearbox has good mechanical quality and steady operating performance. It has high mechanical efficiency, with new design, and it's very easy to operate. The flange connecting to valve is according to ISO5211.

Product Parameters

| Model | YJ-1 -S-L |

YJ-2 -S-L |

YJ-2J -S-L |

YJ-3 -S-L |

YJ-3J -S-L |

YJ-4 -S-L |

YJ-4J -S-L |

YJ-5 -S-L |

YJ-5J -S-L |

YJ-6 -S-L |

YJ-6J -S-L |

YJ-7 -S-L |

YJ-7X -S-L |

YJ-7J -S-L |

YJ-8 -S-L |

YJ-8J -S-L |

YJ-9 -S-L |

YJ-9J -S-L |

YJ-10 -S-L |

YJ-11 -S-L |

YJ-12 -S-L |

|

| Ratio | 78:1 | 78:1 | 127:1 | 200:1 | 375:1 | 495:1 | 798:1 | 868:1 | 938:1 | 1100:1 | 2067:1 | 2260:1 | 3030::1 | 3960:1 | 5535:1 | 5900:1 | 7760:1 | 8526:1 | 9660:1 | 14130:1 | 19320:1 | |

| Max output torque N.m |

1300 | 1600 | 3000 | 4500 | 7500 | 12000 | 16500 | 23000 | 28000 | 32000 | 48000 | 63000 | 80000 | 100000 | 140000 | 190000 | 250000 | 350000 | 400000 | 650000 | 850000 | |

| Max stem diameter | 42 | 50 | 60 | 60 | 75 | 90 | 110 | 110 | 120 | 120 | 145 | 160 | 170 | 180 | 200 | 210 | 220 | 270 | 300 | 380 | 420 | |

| Flange | F12 | F14 | F16 | F16 | F20 | F25 | F30 | F30 | F35 | F35 | F40 | F40 | F48 | F48 | F48 | F60 | F60 | F60 | F80 | F100 | F100 | |

| φD | 150 | 175 | 210 | 210 | 250 | 300 | 350 | 350 | 415 | 415 | 475 | 475 | 560 | 560 | 560 | 686 | 686 | 686 | 900 | 1200 | 1200 | |

| PCD | D0 | 125 | 140 | 165 | 165 | 205 | 254 | 298 | 298 | 356 | 356 | 406 | 406 | 483 | 483 | 483 | 603 | 603 | 603 | 813 | 1042 | 1042 |

| N-H-DP | 4-M12-18 | 4-M16-20 | 4-M20-30 | 4-M20-30 | 8-M16-24 | 8-M16-24 | 8-M20-30 | 8-M20-30 | 8-M30-45 | 8-M30-40 | 8-M36-54 | 8-M36-54 | 12-M36-54 | 12-M36-54 | 12-M36-54 | 20-M36-54 | 20-M36-54 | 20-M36-54 | 20-M42-65 | 32-M42-65 | 32-M42-65 | |

Company Profile

FAQ

Q: What's your main products?

A: Our main products are worm gearbox, bevel gearbox and spur gearbox for gate valve, globe valve, ball valve, butterfly valve and etc.

Q: How long is your delivery time?

A: Delivery time was depends on the quantity of the order and our inventory, normally is 10~15 days.

Q: Term of payment?

A: T/T 30% in advance, T/T balance before shipment.

Q: Can you provide free sample?

A: Yes, we can provide the sample for free, but the shipping costs need paid by yourself.

Q: Could you specially design and produce according to client's requirements?

A: Yes, we can

If any other questions about our products, welcome to contact us.

| Application: | Industry Valves |

|---|---|

| Function: | Change Drive Torque |

| Type: | Worm Gear Box |

| Material: | Ductile Iron, carbon Steel (Customizable) |

| Painting: | Blue, Grey, Black (Customizable) |

| Operation: | Manual |

| Customization: |

Available

| Customized Request |

|---|

Is it Possible to Reverse the Direction of a Worm Gearbox?

Yes, it is possible to reverse the direction of a worm gearbox by changing the orientation of either the input or output shaft. However, reversing the direction of a worm gearbox can have some implications that need to be considered:

- Efficiency: Reversing the direction of a worm gearbox can potentially affect its efficiency. Worm gearboxes are typically more efficient in one direction of rotation due to the design of the worm and worm wheel.

- Backlash: Reversing the direction of rotation might lead to increased backlash or play in the gearbox, which can impact precision and smooth operation.

- Lubrication: Depending on the gearbox's design, reversing the direction could affect lubrication distribution and lead to uneven wear on the gear teeth.

- Load: Reversing the direction might also impact the gearbox's load-carrying capacity, especially if it's designed for predominantly one-way operation.

- Noise and Vibration: Direction reversal can sometimes result in increased noise and vibration due to changes in gear engagement and meshing behavior.

If you need to reverse the direction of a worm gearbox, it's advisable to consult the gearbox manufacturer's guidelines and recommendations. They can provide insights into whether the specific gearbox model is suitable for reversible operation and any precautions or adjustments needed to ensure proper functioning.

Energy Efficiency of a Worm Gearbox: What to Expect

The energy efficiency of a worm gearbox is an important factor to consider when evaluating its performance. Here's what you can expect in terms of energy efficiency:

- Typical Efficiency Range: Worm gearboxes are known for their compact size and high gear reduction capabilities, but they can exhibit lower energy efficiency compared to other types of gearboxes. The efficiency of a worm gearbox typically falls in the range of 50% to 90%, depending on various factors such as design, manufacturing quality, lubrication, and load conditions.

- Inherent Losses: Worm gearboxes inherently involve sliding contact between the worm and worm wheel. This sliding contact generates friction, leading to energy losses in the form of heat. The sliding action also contributes to lower efficiency when compared to gearboxes with rolling contact.

- Helical-Worm Design: Some manufacturers offer helical-worm gearbox designs that combine elements of helical and worm gearing. These designs aim to improve efficiency by incorporating helical gears in the reduction stage, which can lead to higher efficiency compared to traditional worm gearboxes.

- Lubrication: Proper lubrication plays a significant role in minimizing friction and improving energy efficiency. Using high-quality lubricants and ensuring the gearbox is adequately lubricated can help reduce losses due to friction.

- Application Considerations: While worm gearboxes might have lower energy efficiency compared to other types of gearboxes, they still offer advantages in terms of compactness, high torque transmission, and simplicity. Therefore, the decision to use a worm gearbox should consider the specific requirements of the application, including the trade-off between energy efficiency and other performance factors.

When selecting a worm gearbox, it's essential to consider the trade-offs between energy efficiency, torque transmission, gearbox size, and the specific needs of the application. Regular maintenance, proper lubrication, and selecting a well-designed gearbox can contribute to achieving the best possible energy efficiency within the limitations of worm gearbox technology.

Advantages of Using a Worm Reducer in Mechanical Systems

Worm reducers offer several advantages that make them suitable for various mechanical systems:

- High Gear Reduction Ratio: Worm gearboxes provide significant speed reduction, making them ideal for applications that require a high gear reduction ratio without the need for multiple gears.

- Compact Design: Worm reducers have a compact and space-saving design, allowing them to be used in applications with limited space.

- Self-Locking: Worm gearboxes exhibit self-locking properties, which means that the worm screw can prevent the worm wheel from reversing its motion. This is beneficial for applications where the gearbox needs to hold a load in place without external braking mechanisms.

- Smooth and Quiet Operation: Worm gearboxes operate with a sliding motion between the teeth, resulting in smoother and quieter operation compared to some other types of gearboxes.

- High Torque Transmission: Worm gearboxes can transmit high torque levels, making them suitable for applications that require powerful torque output.

- Heat Dissipation: The sliding action between the worm screw and the worm wheel contributes to heat dissipation, which can be advantageous in applications that generate heat during operation.

- Stable Performance: Worm reducers offer stable and reliable performance, making them suitable for continuous operation in various industrial and mechanical systems.

Despite these advantages, it's important to note that worm gearboxes also have limitations, such as lower efficiency compared to other gear types due to the sliding motion and potential for higher heat generation. Therefore, selecting the appropriate type of gearbox depends on the specific requirements and constraints of the application.

editor by CX 2023-09-15

China Custom UL/FM Butterfly Valve C/W Signal Gearbox Wafer Type with Hot selling

Product Description

UL/FM Butterfly valve c/w Signal Gearbox Wafer type

Butterfly Valve

Model: WD-371X/WD-371Y

Fire Protection UL/FM wafer type Butterfly valve

Technical Features

- Conforms: ANSI / AWWA C606 Standard Clear Waterway design

- Connections: Wafer Ends

- Sizes: 2", 2½", 3", 4", 5", 6", 8", 10", 12"

- Approvals: UL, ULC, FM

- Maximum Working Pressure: 21 BAR / 300 CHINAMFG (Maximum Testing Pressure: 600 PSI) conforms to UL1091 & ULC/ORD-C1091 & FM class 1112 Maximum Working Temperature: -20°C to 80°C

- Design Standard: API 609

- Application: Indoor & Outdoor Use

- Epoxy coated interior and exterior by Electrostatic Spray conforms to AWWA C550

- Seat Disc Resilient CHINAMFG Coated

- Factory Installed Supervisory Tamper Switch Assembly

- Top Flange Standard ISO5211 / 1

- Design and materials are subjected to change without any notice

| Media: | Water |

|---|---|

| Driving Mode: | Worm Gear |

| Connection Form: | Wafer |

| Structure: | Centre Sealing |

| Seal Form: | Force Sealed |

| Valve Stem: | Normal |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Is it Possible to Reverse the Direction of a Worm Gearbox?

Yes, it is possible to reverse the direction of a worm gearbox by changing the orientation of either the input or output shaft. However, reversing the direction of a worm gearbox can have some implications that need to be considered:

- Efficiency: Reversing the direction of a worm gearbox can potentially affect its efficiency. Worm gearboxes are typically more efficient in one direction of rotation due to the design of the worm and worm wheel.

- Backlash: Reversing the direction of rotation might lead to increased backlash or play in the gearbox, which can impact precision and smooth operation.

- Lubrication: Depending on the gearbox's design, reversing the direction could affect lubrication distribution and lead to uneven wear on the gear teeth.

- Load: Reversing the direction might also impact the gearbox's load-carrying capacity, especially if it's designed for predominantly one-way operation.

- Noise and Vibration: Direction reversal can sometimes result in increased noise and vibration due to changes in gear engagement and meshing behavior.

If you need to reverse the direction of a worm gearbox, it's advisable to consult the gearbox manufacturer's guidelines and recommendations. They can provide insights into whether the specific gearbox model is suitable for reversible operation and any precautions or adjustments needed to ensure proper functioning.

Does a Worm Reducer Require Frequent Maintenance?

Worm reducers generally require less frequent maintenance compared to some other types of gearboxes due to their design and operating characteristics. However, maintenance is still essential to ensure optimal performance and longevity. Here are some key points to consider:

- Lubrication: Proper lubrication is crucial for worm gearboxes. Regularly check the lubricant level and quality to prevent wear and overheating. Lubricant should be changed as recommended by the manufacturer.

- Inspections: Periodically inspect the gearbox for signs of wear, damage, or oil leaks. Check for any unusual noises, vibrations, or changes in performance that could indicate a problem.

- Tightening and Alignment: Check and tighten any loose fasteners and ensure that the gearbox is properly aligned. Misalignment can lead to increased wear and reduced efficiency.

- Seal Maintenance: Inspect and maintain seals to prevent oil leakage and contaminants from entering the gearbox.

- Cleaning: Keep the gearbox clean from debris and contaminants that could affect its performance. Regular cleaning can prevent premature wear and damage.

- Load and Speed: Ensure that the gearbox is operating within its rated load and speed limits. Exceeding these limits can lead to accelerated wear and potential failure.

- Environmental Conditions: Consider the operating environment of the gearbox. Extreme temperatures, humidity, and other factors can impact the gearbox's performance and longevity.

While worm gearboxes are known for their durability and self-locking feature, neglecting maintenance can lead to premature wear, reduced efficiency, and potential breakdowns. Following the manufacturer's recommendations for maintenance intervals and procedures is essential to keep the worm reducer in optimal condition.

Preventing Backlash in a Worm Gearbox

Backlash in a worm gearbox can lead to reduced accuracy, positioning errors, and decreased overall efficiency. Here are steps to prevent or minimize backlash:

- High-Quality Components: Use high-quality worm gears and worm wheels with tight manufacturing tolerances. Precision components will help reduce backlash.

- Proper Meshing: Ensure the worm gear and worm wheel are properly aligned and meshed. Improper meshing can lead to increased backlash.

- Preload: Applying a small amount of preload to the worm gear can help reduce backlash. However, excessive preload can increase friction and wear.

- Anti-Backlash Mechanisms: Consider using anti-backlash mechanisms, such as spring-loaded systems or adjustable shims, to compensate for any inherent backlash.

- Lubrication: Proper lubrication can reduce friction and play a role in minimizing backlash. Use a lubricant that provides good film strength and reduces wear.

- Maintenance: Regularly inspect and maintain the gearbox to identify and address any changes in backlash over time.

It's important to strike a balance between reducing backlash and maintaining smooth operation. Consulting with gearbox experts and following manufacturer guidelines will help you optimize your worm gearbox's performance while minimizing backlash.

editor by CX 2023-09-15

China wholesaler IP67 Gearbox Suitable for The Cock of Ball Valve and Butterfly Valve comer gearbox

Product Description

Description

This is a right-angle rotating gear driver, using aluminum alloy precision die-casting shell, suitable for the cock of ball valve and butterfly valve, it is driven by worm gear and has self-locking function, and adopts tapered roller bearing to make The operation of the gearbox is more convenient and efficient. The stem nut can be made into a CHINAMFG or separate structure according to customer requirements, and the mounting flange adopts the ISO5211 international standard, so it can be more easily installed with the valve. The overall protection level can reach IP67, and for some special environments, it canalso be made into IP68 level.

| NO. | Item | Material |

| 1 | Bolt | SS304 |

| 2 | Pointer | ABS resin |

| 3 | Cover | Aluminium |

| 4 | O-Ring | NBR70 |

| 5 | Pin | Steel black |

| 6 | Wom gear | Ductile iron |

| 7 | Rear seal | NBR 70 |

| 8 | Body | Aluminium |

| 9 | Adjusting bolt | Steel black |

| 10 | Adjusting bolt gasket | SS304 |

| 11 | Adjusting nut | SS304 |

| 12 | Adjusting nut sheath | NBR 70 |

| 13 | Bearing | Powder metallurgy |

| 14 | Worm | Carbon steel 45# |

| 15 | Front seal | NBR70 |

| 16 | Rotating shaft | SS304 |

| 17 | Hand wheel | Carbon steel polyster coating |

| 18 | Pin | Steel black |

| Model | HAM1(19070) | HAM2(19092) | HAM3(19102) | HAM4(19125) | HAM5(19140) | |

| Technical-parameters | ||||||

| Ratio | 40:01:00 | 37:01:00 | 36:01:00 | 36:01:00 | 50:01:00 | |

| Oitput torque(N.m) | 180 | 300 | 540 | 675 | 1500 | |

| Stemdia,d(mm) | 30 | 32 | 43 | 43 | 54 | |

| Mid-B-vaive(EPDM)DN | DN32-100 | DN100-200 | DN200-250 | DN250-350 | DN350-400 | |

| D-eccentric-B-valve(EPDM)DN | ||||||

| Weight(Kg) | 1.2 | 2 | 2.8 | 4.8 | 11 | |

| Connection-size | ||||||

| Flange dia-D(mm) | 80 | 100 | 120 | 142 | 175 | |

| PCD | D1(ISO5211) | 50/70 | 70/90 | 70/102 | 102/125 | 102/125/140 |

| 4-M6X10/4-M8X12 | 4-M8X12/4-M10X12 | 4-M8X10/4-M10X15 | 4-M8X10/4-M12X18 | 4-M8X10/4-M16X24 | ||

| S | 8/9/11/14/17 | 9/1l/14/17 | 17/19/22 | 19/22/24 | 22/24/27 | |

| 2-b | -- | -- | -- | -- | -- | |

| R(deep) | -- | -- | -- | -- | -- | |

| Appearance-size | ||||||

| L | 115 | 130 | 150 | 180 | 220 | |

| L1 | 50 | 58 | 65 | 80 | 95 | |

| L2 | 42 | 50 | 60 | 60 | 78 | |

| H | 48 | 58 | 58 | 74 | 84 | |

| H1 | 19 | 18 | 18 | 21 | 51 | |

| Handwheel | d1 | 20 | 20 | 20 | 20 | 25 |

| L3 | 160 | 160 | 215 | 225 | 325 | |

| W | 140 | 200 | 250 | 300 | 400 | |

1. Question:What is your main products?

Answer:Our main products are Pneumatic Actuators, Electric Actuators, Actuated Valves And Valve actuators Accessories..

2. Question:Are you a trader or manufacturer ?

Answer: We are the pneumatic actuators and electric actuators manufacturer , we have ability to do the customization products with experienced team, And we have own factory and production line.

3. Question:How do your make the quality guarantee for actuators?

Answer:We have our own quality control system for incoming and outgoing of the materials, every product will be under controlled and tested before delivery to our customer , and we also provide 18 months guarantee ,beside we provide technical supporting .

4. Question:When can I receive the Price of valve actuators ?

Answer:We will give the Quotation Within 24 hours after we get your inquiry .Or Your can call or message us if it's quite urgently.

5. Question:How to order our pneumatic actuators and electric actuators ?

Answer:Please send us your inquiry by Email, , etc. we need to know the following informations before giving the formal Quotation.

1) Product information in details, Quantity, Other requirements

2) Delivery time required

6. Question:How can I get a sample to check your quality?

Answer:Contact with our sales expert to arrange the sample delivery. Please send us the details of the sample before placing the order.

7. Question:Shall we pay the sample cost and transportation cost ?

Answer:We will provide the sample by free of charge. Your will bear the freight cost.

8. Question:How long to prepare the sample ?

Answer:Most of our products are under regular production and some of them we keep in stocks.

9. Question:How to delivery the sample to our place?

Answer:Your can provide your forwarders contacts if any, or we will arrange it for you.

10. Question:What about the delivery date if we place the formal order ?

Answer:Usually it takes 15~20days on the production .We know that on-time delivery is very crucial to our customers to meet dead-lines.

We monitor and expedite our supply chain to ensure that we delivery our products to our customers on-time all the time.

| Application: | Motor |

|---|---|

| Function: | Change Drive Direction, Speed Changing |

| Layout: | Coaxial |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Double-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Calculating Gear Ratio in a Worm Reducer

The gear ratio in a worm reducer is determined by the number of teeth on the worm wheel (also known as the worm gear) and the number of threads on the worm shaft. The gear ratio formula for a worm reducer is:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Shaft

For example, if the worm wheel has 60 teeth and the worm shaft has a single thread, the gear ratio would be 60:1.

It's important to note that worm reducers have an inherent self-locking property due to the angle of the worm threads. As a result, the gear ratio also affects the mechanical advantage and the system's ability to resist backdriving.

When calculating the gear ratio, ensure that the worm reducer is properly designed and that the gear ratio aligns with the desired mechanical characteristics for your application. Additionally, consider factors such as efficiency, load capacity, and speed limitations when selecting a gear ratio for a worm reducer.

Worm Gearbox Applications in Robotics and Automation

Worm gearboxes play a crucial role in various robotics and automation applications due to their unique characteristics and benefits. Here are some common applications where worm gearboxes are used:

- Robotic Arm Movement: Worm gearboxes are employed in robotic arms to provide precise and controlled movement. The self-locking property of worm gearboxes helps maintain the arm's position without requiring additional brakes.

- Conveyor Systems: In automated production lines, worm gearboxes are used to drive conveyor belts and move materials or products along assembly lines with accuracy.

- Precision Positioning: Worm gearboxes are used in precision positioning systems, such as those found in pick-and-place robots and CNC machines. They ensure accurate and repeatable movements.

- Pan and Tilt Mechanisms: Worm gearboxes are utilized in pan and tilt mechanisms of surveillance cameras, robotic cameras, and sensors. The self-locking feature helps stabilize and maintain the desired angle.

- Automated Gates and Doors: Worm gearboxes are used in automated gate and door systems to control their opening and closing movements smoothly and safely.

- Material Handling: Robots in warehouses and distribution centers use worm gearboxes to manipulate and lift objects, enhancing efficiency in material handling.

- Medical Robotics: Worm gearboxes are employed in medical robots for surgical procedures, diagnostic equipment, and rehabilitation devices, ensuring precise and controlled movements.

- Industrial Robots: Industrial robots rely on worm gearboxes for various tasks, including welding, painting, assembly, and packaging, where precise movements are essential.

- Automated Testing Equipment: In testing and inspection applications, worm gearboxes provide the necessary movement and positioning for accurate testing and measurements.

- Food and Beverage Industry: Worm gearboxes are used in automated food processing and packaging systems, ensuring hygienic and precise movement of products.

Worm gearboxes are preferred in these applications due to their compact size, high torque output, self-locking feature, and ability to provide a right-angle drive. However, selecting the right gearbox requires considering factors such as load, speed, efficiency, and environmental conditions.

Advantages of Using a Worm Reducer in Mechanical Systems

Worm reducers offer several advantages that make them suitable for various mechanical systems:

- High Gear Reduction Ratio: Worm gearboxes provide significant speed reduction, making them ideal for applications that require a high gear reduction ratio without the need for multiple gears.

- Compact Design: Worm reducers have a compact and space-saving design, allowing them to be used in applications with limited space.

- Self-Locking: Worm gearboxes exhibit self-locking properties, which means that the worm screw can prevent the worm wheel from reversing its motion. This is beneficial for applications where the gearbox needs to hold a load in place without external braking mechanisms.

- Smooth and Quiet Operation: Worm gearboxes operate with a sliding motion between the teeth, resulting in smoother and quieter operation compared to some other types of gearboxes.

- High Torque Transmission: Worm gearboxes can transmit high torque levels, making them suitable for applications that require powerful torque output.

- Heat Dissipation: The sliding action between the worm screw and the worm wheel contributes to heat dissipation, which can be advantageous in applications that generate heat during operation.

- Stable Performance: Worm reducers offer stable and reliable performance, making them suitable for continuous operation in various industrial and mechanical systems.

Despite these advantages, it's important to note that worm gearboxes also have limitations, such as lower efficiency compared to other gear types due to the sliding motion and potential for higher heat generation. Therefore, selecting the appropriate type of gearbox depends on the specific requirements and constraints of the application.

editor by CX 2023-09-14