Product Description

Product Description

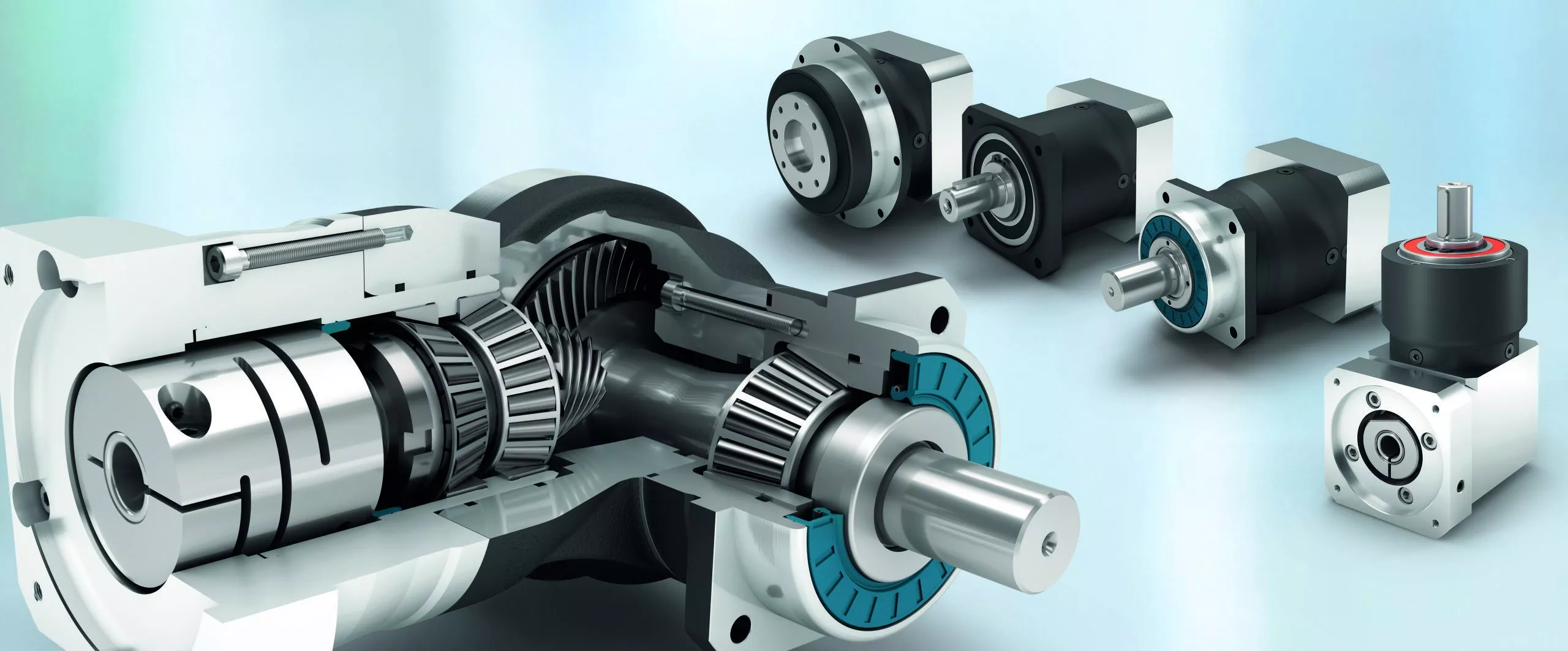

NF140 SERIES planetary precision reducer series adopt the internal structure of the integrated design concept and processing technology and are equipped with high strength tapered roller bearings and angular contact bearing structure. They are characterised by high torque, high precision, high inertia and super durability. They are used in automotive production lines, truss manipulators, robotics, new energy production lines, photovoltaic equipment, machine tools and other related industries. Our products are manufactured using unique design and processing technology and high-end machining centres in Germany and Japan, and some imported equipment are manufactured using customised machining centres, meeting our production process and strict quality control and other standardised operations.

Product Name: High Precision Planetary Gearbox

Product Series:NF140 Series

Features:High torque,high precision,high inertia,high durability

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High precision

High inertia

Super durability

Detailed Photos

Product Parameters

| Segment number | Double segment | |||||||||||||||||

| Ratio | i | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | ||||

| Rated output torque | Nm | 320 | 510 | 610 | 570 | 520 | 570 | 420 | 610 | 570 | 520 | 470 | 420 | 420 | ||||

| Emergency stop torque | Nm | Three times of Maximum Output Torque | ||||||||||||||||

| Rated input speed | Rpm | 3000 | ||||||||||||||||

| Max input speed | Rpm | 6000 | ||||||||||||||||

| Ultraprecise backlash | arcmin | ≤3 | ||||||||||||||||

| Precision backlash | arcmin | ≤5 | ||||||||||||||||

| Standard backlash | arcmin | ≤7 | ||||||||||||||||

| Torsional rigidity | Nm/arcmin | 50 | ||||||||||||||||

| Max.bending moment | Nm | 14000 | ||||||||||||||||

| Max.axial force | N | 11400 | ||||||||||||||||

| Service life | hr | 30000(15000 under continuous operation) | ||||||||||||||||

| Efficiency | % | ≥94% | ||||||||||||||||

| Weight | kg | 16.6 | ||||||||||||||||

| Operating Temperature | ºC | -10ºC~+90ºC | ||||||||||||||||

| Lubrication | Synthetic grease | |||||||||||||||||

| Protection class | IP64 | |||||||||||||||||

| Mounting Position | All directions | |||||||||||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤65 | ||||||||||||||||

| Rotary inertia | Kg·cm² | 2.71 | 2.57 | |||||||||||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Layout: | Plantery Gearbox |

| Gear Shape: | Helical Tooth |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Can you provide real-world examples of products that use gear reducer technology?

Certainly! Gear reducer technology is widely used in various industries and products to enhance performance and efficiency. Here are some real-world examples:

1. Industrial Machinery: Gear reducers are commonly used in manufacturing machinery, such as conveyor systems, material handling equipment, and assembly lines, where they help control speed and torque for precise operations.

2. Wind Turbines: Wind turbines utilize gear reducers to transform the low rotational speed of the wind turbine rotor into the higher speed needed for electricity generation, optimizing energy conversion.

3. Automotive Transmissions: Automobiles use gear reducers as part of their transmissions to optimize power delivery from the engine to the wheels, allowing the vehicle to operate efficiently at different speeds.

4. Robotics: Robotic systems rely on gear reducers to control the movement and articulation of robot arms, enabling precise and controlled motion for various applications.

5. Printing Presses: Gear reducers are integral to printing presses, ensuring accurate and synchronized movement of printing plates, rollers, and paper feed mechanisms.

6. Conveyor Belts: Conveyor systems in industries like mining, agriculture, and logistics use gear reducers to regulate the movement of materials along the conveyor belts.

7. Packaging Machinery: Gear reducers play a crucial role in packaging machines, controlling the speed and movement of packaging materials, filling mechanisms, and sealing components.

8. Cranes and Hoists: Cranes and hoists rely on gear reducers to lift heavy loads with precision and control, ensuring safe and efficient material handling.

9. Pumps and Compressors: Gear reducers are utilized in pumps and compressors to regulate fluid flow and pressure, optimizing energy usage in fluid transportation systems.

10. Agriculture Equipment: Tractors and other agricultural machinery use gear reducers to adjust the speed and power delivery for different tasks, such as plowing, planting, and harvesting.

These examples demonstrate the diverse applications of gear reducer technology across various industries, showcasing their role in enhancing efficiency, control, and performance in a wide range of products and systems.

Can gear reducers be used for both speed reduction and speed increase?

Yes, gear reducers can be utilized for both speed reduction and speed increase, depending on their design and arrangement. The functionality to either decrease or increase rotational speed is achieved by altering the arrangement of gears within the gearbox.

1. Speed Reduction: In speed reduction applications, a gear reducer is designed with gears of different sizes. The input shaft connects to a larger gear, while the output shaft is connected to a smaller gear. As the input shaft rotates, the larger gear turns the smaller gear, resulting in a decrease in output speed compared to the input speed. This configuration provides higher torque output at a lower speed, making it suitable for applications that require increased force or torque.

2. Speed Increase: For speed increase, the gear arrangement is reversed. The input shaft connects to a smaller gear, while the output shaft is connected to a larger gear. As the input shaft rotates, the smaller gear drives the larger gear, resulting in an increase in output speed compared to the input speed. However, the torque output is lower than that of speed reduction configurations.

By choosing the appropriate gear ratios and arrangement, gear reducers can be customized to meet specific speed and torque requirements for various industrial applications. It's important to select the right type of gear reducer and configure it correctly to achieve the desired speed reduction or speed increase.

What are the benefits of using a gear reducer in industrial applications?

Gear reducers offer several benefits that make them indispensable in various industrial applications:

1. Speed Reduction: Gear reducers allow the reduction of high-speed input from motors or engines to lower, more usable output speeds for specific applications, ensuring proper equipment operation and safety.

2. Torque Increase: By leveraging the mechanical advantage of gear ratios, gear reducers can significantly increase torque output, enabling the handling of heavy loads and providing the necessary power for tasks such as lifting, conveying, and processing.

3. Precise Control: Gear reducers enable fine-tuning of rotational speed and torque, providing precise control over machinery and processes, which is crucial in industries like manufacturing, material handling, and robotics.

4. Shock Load Absorption: Gear reducers can absorb and dampen sudden shocks or changes in load, protecting both the machinery and connected components from abrupt forces that could otherwise lead to damage.

5. Versatility: With various gear types (e.g., spur, helical, worm) and designs, gear reducers can be tailored to different applications, including those requiring specific speed ratios, torque ranges, and environmental conditions.

6. Efficient Power Transmission: Gear reducers offer high mechanical efficiency, minimizing energy loss during power transmission, which is especially valuable in energy-conscious industries.

7. Compact Design: Gear reducers provide a compact solution for transmitting power and adjusting speeds, making them suitable for installations with space constraints.

8. Reliability and Longevity: Well-designed and properly maintained gear reducers can offer extended service life, contributing to reduced downtime and maintenance costs.

Overall, gear reducers enhance the performance, efficiency, and reliability of industrial equipment, making them essential components in a wide range of applications across various industries.

editor by CX 2024-01-15

China Custom Desboer Nb180 Series Double Segment High Precision Standard Backlash High Torque High Rigidity Helical Gear Planetary Gearbox for Servo Motor. gearbox engine

Product Description

Product Description

NB180 series adopts the design of integrating its sun gear and input shaft, the design of integrating its output structure. Using high- strength bearing, the product itself is characterized by high load, high precision, and low noise, focusing on the use of automation equipment, various types of packaging, printing, lithium-ion, LCD screens, robots, palletizers, woodworking, doors and windows and other industry sectors.

Product Name: High Precision Planetary Gearbox

Product Series: NB180 Series

Product features: high precision, high load, low noise.

Product Description:

Integrated design concept with high strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimises power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High precision

High load

Low noise

Detailed Photos

Product Parameters

| Segment number | Double segment | |||||||||||||

| Ratio | i | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 |

| Rated output torque | Nm | 550 | 990 | 1140 | 1040 | 1040 | 950 | 850 | 1140 | 1040 | 1040 | 950 | 850 | 850 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | ||||||||||||

| Rated input speed | Rpm | 3000 | ||||||||||||

| Max input speed | Rpm | 6000 | ||||||||||||

| Ultraprecise backlash | arcmin | ≤3 | ||||||||||||

| Precision backlash | arcmin | ≤5 | ||||||||||||

| Standard backlash | arcmin | ≤7 | ||||||||||||

| Torsional rigidity | Nm/arcmin | 145 | ||||||||||||

| Max.bending moment | Nm | 14500 | ||||||||||||

| Max.axial force | N | 7250 | ||||||||||||

| Service life | hr | 20000(10000 under continuous operation) | ||||||||||||

| Efficiency | % | ≥94% | ||||||||||||

| Weight | kg | 33 | ||||||||||||

| Operating Temperature | ºC | -10ºC~+90ºC | ||||||||||||

| Lubrication | Synthetic grease | |||||||||||||

| Protection class | IP64 | |||||||||||||

| Mounting Position | All directions | |||||||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤67 | ||||||||||||

| Rotary inertia | Kg·cm² | 7.42 | 7.03 | |||||||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | All Direction |

| Layout: | Planetary Gearbox |

| Gear Shape: | Helical Gear |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Sudden Changes in Direction and Speed with Servo Gearboxes

Servo gearboxes are designed to handle sudden changes in direction and speed effectively, ensuring precise motion control even during dynamic operations. They employ several mechanisms to address these challenges:

1. Acceleration and Deceleration Profiles: Servo systems can be programmed with specific acceleration and deceleration profiles. This means that when a sudden change in speed or direction is commanded, the system can ramp up or down the speed smoothly, reducing the impact of sudden changes on the mechanical components.

2. Closed-Loop Control: Servo systems operate in a closed-loop configuration, where feedback sensors continuously monitor the actual position and speed of the system. When a sudden change is commanded, the controller can make real-time adjustments to ensure the system reaches the desired position accurately and smoothly.

3. Torque Control: Servo gearboxes are designed to provide high torque output even at low speeds. This is crucial for handling sudden changes in direction and speed, as the gearbox can deliver the required torque to quickly accelerate or decelerate the load.

4. Dynamic Response: Servo systems have fast dynamic response capabilities, which means they can quickly adapt to changes in input commands. This responsiveness allows the system to handle sudden changes in direction and speed without sacrificing accuracy or stability.

5. Electronic Damping: Some advanced servo systems incorporate electronic damping mechanisms that can be adjusted based on the application's requirements. This feature helps dampen vibrations and oscillations that may occur during sudden changes in motion.

6. Overcurrent and Overvoltage Protection: Servo systems are equipped with protection mechanisms that detect excessive currents or voltages. If a sudden change in direction or speed causes abnormal loads or voltages, the system can take corrective actions to prevent damage.

Overall, servo gearboxes excel in handling sudden changes in direction and speed by leveraging their closed-loop control, high torque output, and fast dynamic response capabilities. These features allow them to provide accurate and reliable motion control in dynamic and rapidly changing operating conditions.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application's requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by CX 2023-10-08