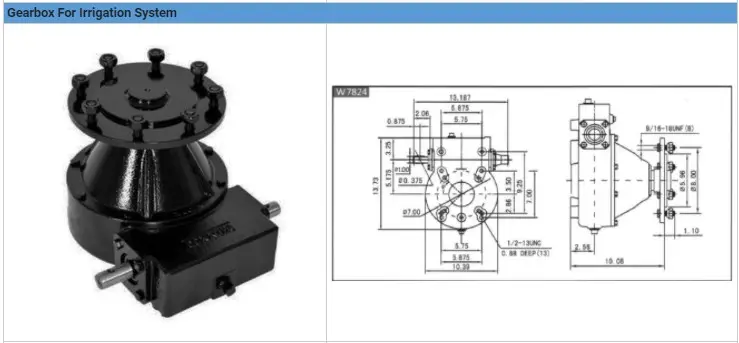

Product Description

Agricultural 540rpm 90 Degree Bevel Gearbox for Lawn Mower Rotary Cutter Tiller Cultivator Irrigation Fertilizer Spreader Hole Digger Gear Tractor Pto Shaft

Our product can be adapted: see the diagram and the chart below. Please give us the required model name so we can provide you the most accurate quotation.

This chart if for reference, if you need different features, provide us all relevant details for your project and we will be glad to help you finding the product matching your need at the best quality with the lowest price.

Please note the price and the MOQ may vary regarding the product you chose: do not hesitate to contact us to know more!

Related Products

Factory

Application

Extensive use for agricultural machines

Guarantee: High precision, high wear resistance, low noise, smooth and steady, high strength

Our factory

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Agricultural Gearbox |

|---|---|

| Usage: | Farmland Infrastructure, Agricultural Machine |

| Material: | Carbon Steel |

| Power Source: | Electricity |

| Weight: | OEM |

| After-sales Service: | Installation Guide |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Handling Different Soil and Terrain with Irrigation Gearboxes

Irrigation gearboxes are designed to effectively handle various types of soil and terrain, ensuring reliable and efficient water distribution. Here's how they adapt to different conditions:

- Variable Torque: Different soil types require varying levels of force to move irrigation equipment. Irrigation gearboxes can adjust their torque output to accommodate softer or harder soil, ensuring the equipment can move smoothly even in challenging conditions.

- Traction Control: In hilly or uneven terrains, traction can be an issue. Irrigation gearboxes are equipped with features that enhance traction, such as slip-resistant surfaces or adjustable torque settings. This prevents slippage and maintains consistent movement on different terrains.

- Controlled Speed: Different terrains may demand different speeds to ensure uniform water distribution. Irrigation gearboxes allow operators to adjust the speed according to the terrain, preventing excessive water application in certain areas and ensuring optimal coverage.

- Adaptable Design: Some irrigation gearboxes have adaptable designs, allowing for easy customization based on the specific terrain and irrigation method. This ensures that the equipment operates efficiently and effectively, regardless of the challenges presented by the terrain.

By offering versatility and adaptability, irrigation gearboxes enable farmers to navigate and irrigate different types of soil and terrains with precision, ensuring consistent water distribution and optimal crop growth.

Enhancing Efficiency of Drip and Sprinkler Irrigation with Irrigation Gearboxes

Irrigation gearboxes play a crucial role in enhancing the efficiency of both drip and sprinkler irrigation systems by ensuring precise water distribution and optimal performance:

- Drip Irrigation: In drip irrigation systems, irrigation gearboxes help regulate the pressure and flow of water in the drip lines. These gearboxes ensure that each plant receives the right amount of water directly at its root zone. By controlling the water delivery, irrigation gearboxes minimize water wastage due to overspray or runoff. Additionally, the ability to adjust water flow helps accommodate different soil types and plant water requirements, contributing to efficient water use.

- Sprinkler Irrigation: For sprinkler irrigation systems, irrigation gearboxes are used in various components, including rotating sprinkler heads and pivoting arms. These gearboxes enable precise control over the direction, angle, and rotation of the sprinkler heads, ensuring uniform coverage of the field. By accurately distributing water over the cultivated area, irrigation gearboxes minimize under-irrigated or over-irrigated spots. This results in improved crop health, reduced water wastage, and increased overall efficiency of the irrigation system.

By incorporating irrigation gearboxes into both drip and sprinkler irrigation setups, farmers can achieve better control over water distribution, reduce water consumption, and enhance the overall efficiency of their irrigation practices.

Benefits of Using an Irrigation Gearbox in Irrigation Systems

Irrigation gearboxes offer several advantages when integrated into irrigation systems for agricultural purposes:

1. Efficient Water Management: Irrigation gearboxes allow precise control over water flow rates, ensuring that crops receive the right amount of water. This efficiency prevents overwatering or underwatering and optimizes water usage.

2. Uniform Water Distribution: By regulating water flow, irrigation gearboxes ensure uniform water distribution across the field. This prevents uneven crop growth and provides consistent moisture to all plants.

3. Customized Irrigation: Modern irrigation gearboxes can be programmed with specific irrigation schedules based on crop needs, weather conditions, and soil moisture levels. This customization enhances water efficiency and crop health.

4. Adaptability to Terrain: Agricultural fields often have varying slopes and terrains. Irrigation gearboxes can be adjusted to accommodate these changes, allowing water to flow evenly and reach all areas of the field.

5. Water Conservation: Precise water distribution minimizes wastage, contributing to water conservation efforts. This is particularly important in regions where water resources are scarce.

6. Increased Crop Yields: Uniform water distribution and efficient moisture management promote healthy crop growth, resulting in higher yields and improved crop quality.

7. Prevention of Waterlogging: Irrigation gearboxes help prevent waterlogging by controlling water levels. This prevents root damage and soil compaction that can occur from excessive water accumulation.

8. Reduction in Labor: Automated irrigation systems equipped with irrigation gearboxes reduce the need for manual intervention. Farmers can set up automated watering schedules, saving time and labor.

9. Environmental Sustainability: Using irrigation gearboxes to optimize water usage aligns with sustainable farming practices and reduces the environmental impact of agriculture.

10. Improved Plant Health: Consistent and controlled water distribution enhances plant health, as it minimizes stress caused by inadequate or excessive watering.

11. Enhanced Crop Management: Irrigation gearboxes enable farmers to easily manage and adjust irrigation schedules, ensuring that crops receive water at optimal times for growth.

12. Return on Investment: While the initial investment may be incurred when installing irrigation systems with gearboxes, the long-term benefits, including increased yields and resource efficiency, often result in a positive return on investment.

Irrigation gearboxes play a pivotal role in modern agricultural practices by optimizing water distribution, enhancing crop productivity, and promoting sustainable irrigation methods.

editor by CX 2024-01-15

China manufacturer Small Farm Tractor 3-Point Hitch Lawn Mower (EFD95) near me factory

Product Description

Flail Mower

1. Transmission: By sturdy toothed belts.

2. Gearbox is made of gravity casting iron. Material performance is better. Not easy broken.

3. With adjustable rear roller, the mowing height can be adjusted.

4. The structure is firm and stable.

5. High welding processes

6. With front protection, it can prevent splashing.

7. Y shape blades, hammer and vertical blades for grass. With double blades.

8. Cat. I universal three-point hitch cardan shaft.

|

Model |

EFD-95 | EFD-105 | EFD-115 | EFD-125 | EFD-135 |

| Dimension(mm) | 1040×700×520 | 1140×700×520 | 1240*700*520 | 1340×700×520 | 1440×700×520 |

| Weight(Kg) | 130 KG | 145Kg | 155KG | 170Kg | 175Kg |

| Cutting Width | 950mm | 1050mm | 1150mm | 1250mm | 1350mm |

| PTO Input Speed | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min |

| Y shape blades | 60 | 72 | 78 | 84 | 84 |

| Power Required | 16-20HP | 20-25HP | 20-30HP | 20-30HP | 20-30HP |

| 3 point linkage | Cat.1 | Cat.1 | Cat.1 | Cat.1 | Cat.1 |

| Packing size(mm) | 1150×750×550 | 1250×750×550 | 1350*750*550 | 1450×750×550 | 1550×750×550 |

Company Profile

HangZhou CZPT Industry & Trade Co., Ltd., is a professional manufacturer and exporter of whole set of agriculture machines and garden tools. Our company was established since 2003 with Hanma Industry Company.

Our main products include rotovator, flail mower, finishing mower, CZPT mower, wood chipper, plow, cultivator, potato harvester/ planter and Japanese tractor parts, etc. Due to our super International quality standard and rapid & excellent after-sales service, CZPT machines are greatly popular in various markets around the world, and already reached to Europe, North America, South America, Australia, almost covers 80 countries in World.

LEFA always believe that we will take better farming life to you by top-quality laser cutting machine & CNC bending machine & professional paint-spraying & strong welding.

PROFESSIONAL PRODUCTION:

1.Professional team with rich experience

2.Powerful factory strength with CE certification

3.Best after-sales service

Packing & Shipping

Packaging Detail: Iron pallet or wooden cases

Delivery Detail: By sea or By air

1. Waterproof packing with the international export standard by 20ft, 40ftcontainer.

Wooden Case or Iron Pallet.

2. The whole set of machines size are large as normal, so we will use Waterproof materials to pack

all of them. The motor, gear box or other easily damaged parts, we will put them into box.

We have a professional shipping department, they will try their best to save your container quantity.

Machine videos in YOUTOBE

EFDL SIDE MOWERS

EFGL SIDE MOWERS

FM FINISHING MOWERS

TM CZPT MOWERS

RT ROTARY TILLERS

https://youtu.be/d3H1-yXUImc AP-90 POTATO HARVESTER

https://youtu.be/AAkgnV_bY80 LF-PT32 POTATO PLANTER

https://youtu.be/66geQQOUTLY wood chipper BX-42

https://youtu.be/iIVOwCTCl_c HAY BALER

FAQ:

Q1. How to buy 3 point rotary tiller?

Inquiry ---------> Quotation -------->Price reasonable ------->Check with specification ----->Proforma Invoice sent ------------>Payment made -------> Producing the items ------->Product shipment -----------> Customer confirm

Q2.How long is the delivery date for agriculture machinery cultivator?

A:In general, we can ship the goods within 30-45 days after receiving your payment. Of course, it also depends on your quantity.

Q3. How can I get to your factory to buy tractor cultivator?

A:We are located in HangZhou, only 1 hour's distance to ZheJiang or HangZhou. You can fly to ZheJiang /HangZhou/HangZhou Airport , the transportation is very convenient

Q4.Do you have stock for rotary tiller?

A:In general, we have some stock, while if you need a bulk order, we still need time to produce it. Of course, we will inform all details you before your payment.

Q5: What's your main products?

A: Our products are covered almost all farm machines and Japanese tractors parts, we can meet your any demands.

Q6. What is your terms of payment?

A: T/T, L/C, Paypal, Western Union

The benefits of using pulleys

A pulley is a mechanical device that converts force into rotation. There are many advantages to using pulleys. Let's take a look at a few of them. This article will describe the advantages, types, applications, and power sources of pulleys. You can then choose the pulley that best suits your specific needs. If you're looking for a new tool to help you with a certain task, this article is for you.

Mechanical advantage

The mechanical advantage of a pulley can be defined as the ratio of applied force to the applied force. The mechanical advantage of a pulley can be calculated by considering several factors, including weight and friction. It can be calculated by the force applied per unit length of rope and the number of pulleys used. In a single-circuit system, the force required to lift a heavy object is equal to the user's body weight.

The mechanical advantage of a pulley can be realized by comparing it to a seesaw. Both uses of rope are suitable for lifting objects. A rope 4 times heavier than a kilo is 4 times as effective. Because the forces on both sides of the pulley are equal, a small force is enough to move a large weight a short distance. The same force can be applied to a large mass to lift it several meters.

After introducing the concept of mechanical advantage, learners will practice using the pulley system. In addition to testing the pulley system, they should also calculate its mechanical advantage. Using either the instructor-provided handout or the learner's workbook, students will determine how easily the pulley system functions. Once they have completed the test, they can discuss their results and how the system can be improved. These courses are best completed as part of a mini-unit or as a standalone main course.

The mechanical advantage of the pulley system is proportional to the number of rope loops. This circuit requires the same force as the dual circuit to lift heavy objects. A single lap requires only a third of the force to lift a double lap, while 3 laps require almost half the energy required for a single lap. The mechanical advantage of the pulley system becomes constant as the number of cycles increases.

The 3:1 Mechanical Advantage system feels like lifting a 300-pound load with 3 feet of rope. The three-foot-long rope moves the load 1 foot high. Understanding the mechanical advantages of pulleys is critical for rescuers when trying to create the perfect pulley system. Ideally, the pulley system will be anchored to a nearby rock, tree, pole or person - if the weight is not too heavy.

Types of pulleys

There are several types of pulleys. V-belt pulleys are the type commonly used in vehicles and electric motors. "V" pulleys require a "V" belt, and some even have multiple V grooves. "V" pulleys are often used in heavy duty applications for power transmission because they reduce the risk of power slippage.

Composite pulleys combine the properties of fixed and movable pulleys. Compound pulleys are able to change the direction of force while requiring relatively low force to move even the heaviest loads. Mechanical advantage is a measure of the effectiveness of a machine or equipment. It can be divided into 3 categories: force, distance and mechanics. Once you understand how each type works, you can design complex machines.

Fixed pulleys: These pulleys are the most basic type of pulleys. They use ropes and slotted wheels to move with the lifted object. Because they are so simple to set up, lifting heavy objects is a breeze. Although the moving object feels light, it is actually heavier than it actually is. These pulleys are used in construction cranes, utility elevators and many different industries.

Compound Pulley System: A pulley pulley is a combination of 2 fixed pulleys and 1 movable pulley. Compound pulley systems are effective for moving heavy objects because they have the largest force multipliers and are flexible enough to change the direction of the force as needed. Composite pulley systems are commonly used in rock climbing, theater curtains and sailing. If you're looking for a pulley system, you can start by evaluating the types of pulleys and their uses.

Construction Pulleys: These are the most basic types of pulleys and have wheel rails. These pulleys can be lifted to great heights and attached to chains or ropes. They allow workers to access equipment or materials from greater heights. They are usually mounted on wheels with axles and secured with ropes. They are essential tools for construction workers. There are many different types of pulleys out there.

energy source

Belts and pulleys are mechanical devices used to transmit energy and rotational motion. The belt is connected to the rotating part of the energy source, and the pulley is mounted on the other. One pulley transmits power to the other, while the other changes the direction of the force. Many devices use this combination, including automobiles, stationary generators, and winches. It is used in many home applications, from conveyors to treadmills. Pulleys are also used for curtains in theater halls.

Pulley systems are an essential part of modern industry and everyday life. Pulleys are used in elevators, construction sites and fitness equipment. They are also used in belt-driven generators as backup power. Despite their simple and seemingly humble beginnings, they have become a versatile tool. From lifting heavy objects to guiding wind turbines, pulley systems are widely used in our daily lives.

The main reason why pulleys are so popular is the mechanical advantage they offer. They can lift a lot of weight by applying very little force over longer distances. For example, a small motor can pull 10 meters of cable, while a large motor can pull 1 meter. Also, the work done is equal to the force times the distance traveled, so the energy delivered to the large motor is the same.

The power source for the pulley system can be cables, belts or ropes. The drive element in a pulley system is usually a rope or cable. A belt is a loop of flexible material that transmits motion from 1 pulley to another. The belt is attached to the shaft and a groove is cut in the pulley. The belt then transfers energy from 1 pulley to the other through the system.

application

A pulley is a mechanical device used to lift heavy objects. They reduce the amount of work required to lift heavy objects and are an excellent choice for many applications. There are several different applications for pulleys, including elevators, grinders, planters, ladder extensions, and mountaineering or rock climbing. Let's take a look at some of the most popular uses for pulleys in modern society. These include:-

A pulley is a mechanical device that changes force. To use, you wrap the rope around it and pull down to lift the object. While this device is very useful, a major limitation of using pulleys is that you still have to apply the same force to lift the object as you would without the pulleys. This is why people use pulleys to move large objects like furniture and cars.

In addition to lifting heavy objects, pulleys are used in elevators, flagpoles and wells. These systems allow people to move heavy objects without straining their backs. Many other examples of pulleys in the home include garage doors, flagpoles, and elevators. They also help raise and lower flagpoles, which can reach several stories high.

There are 2 basic types of pulleys: movable and fixed. Fixed pulleys are attached to a ceiling or other object using 2 ropes. Modern elevators and construction cranes use movable pulleys, as do some weight machines in gyms. Composite pulleys combine movable and fixed pulleys to minimize the force required to move heavy objects.

Another type of fixed pulley is the flagpole. A flagpole can support a country, organization, or anything else that needs to be lifted. A taller flagpole creates a prouder moment for those who support it. The operation of the rope and pulley mechanism is very simple. The user simply attaches the flag to the rope, pulls the pulley, and he or she can watch the flag rise and unfold.

China Professional Agriculture Machinery Alfalfa Cutting Machine Disc Mower Lawn Mower Tractor with Great quality

Product Description

Agriculture machinery Alfalfa Cutting Machine Disc Mower Lawn Mower Tractor

PRODUCT DESCRIPTION

This disc mower is attached to the tractor rear suspension frame, and the power output shaft is used for operation. The machine has 4-8 high-speed rotating Cutterheads. Each cutterhead is equipped with 2 blades. It can work at high speed up to 1-2 hectares per hour with high productivity.

The rotation of cutter-heads of this mower is driven by gear instead of traditional belt drive, which makes the work stable, the failure rate low and the maintenance cost low.

Because of spring suspension and belt rotation, the knife beam is low, easy to rise and fall, it can cut close to the ground, with low cutting stubble, and has a good imitation ability to the ground.

When the cutting blade encounters a big obstacle, it can be knocked back to avoid damage to the blade. The mower relies on the rotating force of the turntable to concentrate the grass in the middle position for easy collection.

Advantage:

1) The disc mower cuts through heavy, high crops without wraping or plugging, as well as for light thin grass.

It is suitable for native grass,alfalfa,corn and other stalks.

2) Rotary disc mower can be raised quickly for turning or transport without adjusting the 3 point hitch.

3) The disc mower siutable for wide range terrains and contours,even uneven and rocky ground.

RODUCT SPECIFICATION

| Model | Unit | 9GRM-1300 | 9GRM-1700 | 9GRM-2100 | 9GRM-2500 |

| Working width | mm | 1250 | 1650 | 2050 | 2360 |

| Overall dimensions (L*W*H) | mm | 2080*1180*780 | 2533*1180*780 | 2950*1280*780 | 3270*1280*780 |

| Quantity of discs | Pc | 3 | 4 | 5 | 6 |

| Quantity of blades | Pc | 6 | 8 | 10 | 12 |

| Working speed | Km/h | 4-10 | |||

| PTO rotation speed | r/min | 540-720 | |||

| Matched Tractor power | hp | 20-50 | 35-80 | 45-85 | 50-110 |

| Machine Weight | kg | 280 | 370 | 400 | 450 |

| Linkage type | Tractor 3 point mounted | ||||

RODUCT SHOW

RELATED PRODUCTS

FAQ

| Q1: Are you a factory or trading company? |

|---|

|

We are a factory with self-supported import and export right with more than 10 years of manufacturing experience. |

| Q2: How can I trust on your company? |

|

We are a fully registered manufacture and exporting company by China Export Registration Authorities. Moreover, our products have been exporting to a number of countries including Switzerland, Russia, Spain, Netherlands, Australia, Peru, Thailand, Pakistan, Indonesia, Tanzania, Nigeria, South Africa, Sudan, Congo etc. The good faith, punctual, strict quality control and reasonable price, throughout is the pledge we to each customer. |

| Q3: Where is your factory located? How can I visit there? |

|

Our factory is located in HangZhou City, ZheJiang Province, China. About 1 hour away from HangZhou Airport. All our clients are warmly welcomed to visit us! |

| Q4: How can I place an order from your website? |

|

It is very easy.Once you find the implement you need on our website and place an inquiry against it, or, get to the inquiry section and leave us a message there with name, country and phone number, we will get in touch with you at the earliest. You can also e-mail us directly or join us on live chat for instantaneous answers. |

| Q5: How can I make the payment? |

|

Payment is made via Telegraphic Transfer (T/T) through the bank against the proforma invoice. |

| Q6: What's the Payment terms? |

|

FOB, the price of the implement without sea shipment costs. |

| Q7: At which port do you usually ship the good? |

|

We usually ship goods via HangZhou, ZheJiang , HangZhou, ZheJiang port of China. |

| Q8. How about the Warranty ? |

|

15 months warranty from the time of the goods arrive at destination. |

COMPANY INTRODUCTION

1) More than 10 years of manufacturing expenrience in the field of general machineries.

2) Professional engineers and test equipments to ensure the quality of each machine.

3) Factory direct selling at competitive prices.

4) Good parts assembled, strictly quality control system.5) Compact structure, beautiful appearance,small volume, light weight, fuel consumption is low, the power is great

6) Start convenient easy, low noise,little vibration,smooth operation,reliable performance.

7) OEM welcome, small order acceptable, ample supply and prompt delivery.

8) YCHS MACHIERY is a manufacturer, have own factories.

9) The biggest advantages: Top quality, Competitive price & Good after-sales service

"Top quality, Competitive price, Good after-sales service" is our big advantages.

Welcome to contact us at any time, sincerely hope we could have cooperation with you.

Have a nice day.

Calculate the ideal mechanical advantage of pulleys

The basic equations for pulleys can be found in this article. It will also cover the different types of pulleys, the ideal mechanical advantages of pulleys, and some common uses of pulley systems. Read on to learn more! After all, a pulley is a simple mechanical device that changes the direction of a force. Learn more about pulleys and their common uses in engineering.

pulley basic equation

Pulleys work the same way as gravity, so they should withstand similar forces. Newton's laws of motion can be used to calculate the forces in a pulley system. The second law of motion applies to forces and accelerations. Similar to this is Newton's third law, which states that the directions of forces are equal and opposite. The fourth law dictates the direction of force. The Fifth Law states that tension is in equilibrium with gravity.

A pulley is a simple mechanism that transmits force by changing direction. They are generally considered to have negligible mass and friction, but this is only an approximation. Pulleys have different uses, from sailboats to farms and large construction cranes. In fact, they are the most versatile mechanisms in any system. Some of their most common applications and equations are listed below.

For example, consider 2 masses m. Those of mass m will be connected by pulleys. The static friction coefficient of the left stop is ms1, and the static friction coefficient of the right stop is ms2. A no-slip equation will contain multiple inequalities. If the 2 blocks are considered to be connected by a pulley, the coefficient of kinetic friction is mk. In other words, the weight of each block carries the same mass, but in the opposite direction.

Types of pulleys

A pulley is a device used to pull and push objects. Pulley systems are ropes, cables, belts or chains. The "drive pulley" is attached to the shaft and moves the driven pulley. They are available in a variety of sizes, and the larger they are, the higher the speed of power transmission. Alternatively, use small pulleys for smaller applications.

Two-wheel pulleys have 2 mechanical advantages. The greater the mechanical advantage, the less force is required to move the object. More wheels lift more weight, but smaller pulleys require less force. In a two-wheel pulley system, the rope is wound around 2 axles and a fixed surface. As you pull on the rope, the shafts above slowly come together.

Compound pulleys have 2 or more rope segments that are pulled up on the load. The mechanical advantage of compound pulleys depends on the number of rope segments and how they are arranged. This type of pulley can increase the force by changing the direction of the rope segment. There are 2 main types of pulleys. Composite pulleys are most commonly used in construction. The ideal mechanical advantage of pulleys is 2 or more.

Construction pulleys are a basic type. They are usually attached to wheel rails and can be lifted to great heights. Combinations of axes are also common. Construction pulleys can be raised to great heights to access materials or equipment. When used in construction, these pulleys are usually made of heavy materials such as wood or metal. They are secured with ropes or chains.

The ideal mechanical advantage of pulleys

The pulley system is a highly complex system with high mechanical advantages. Use a single pulley system to reduce the force required to lift an object by cutting it in half. The mechanical advantage increases as you add more pulleys, such as 6 or seven. To calculate the mechanical advantage of a pulley system, you need to count the number of rope segments between the pulleys. If the free end of the rope is facing down, don't count it. If it's facing up, count. Once you have your number, add it up.

The required mechanical advantage of a pulley is the number of rope segments it has to pull the load. The more rope segments, the lower the force. Therefore, the more rope segments the pulley has, the lower the force. If the rope segments are four, then the ideal mechanical advantage is four. In this case, the composite pulley quadrupled the load force.

The ideal mechanical advantage of a pulley system is the sum of the mechanical force and the force required to lift the load at its output. Typically, a single pulley system uses 2 ropes, and the mechanical force required to lift the load is multiplied by the 2 ropes. For a multi-pulley system, the number of ropes will vary, but the total energy requirement will remain the same. The friction between the rope and pulley increases the force and energy required to lift the load, so the mechanical advantage diminishes over time.

Common uses of pulley systems

A pulley system is a simple mechanical device typically used to lift heavy objects. It consists of a rotating wheel attached to a fixed shaft and a rope attached to it. When the wheel moves, the force applied by the operator is multiplied by the speed of the pulley, and the force is multiplied by the weight of the object being lifted. Common uses for pulley systems include pulling, lifting, and moving heavy objects.

The oil and petroleum industries use pulley systems in a variety of applications. Most commonly, pulleys are used in drilling operations and they are installed on top of the rig to guide the cable. The cable itself is attached to 2 pulleys suspended in the derrick, where they provide mechanical energy to the cable. Using a pulley system in this application provides the force needed to move the cable safely and smoothly.

The main advantage of the pulley system is that it minimizes the force required to lift an object. The force used to lift the object is multiplied by the desired mechanical advantage. The more rope segments, the lower the force required. On the other hand, a compound pulley system can have many segments. Therefore, a compound pulley system can increase the force a worker can exert on an object.

Safety Precautions to Take When Working on Pulley Systems

There are many safety precautions that should be observed when working on a pulley system. The first is to wear proper protective gear. This includes hard hats that protect you from falling objects. Also, gloves may be required. You should limit the amount of movement in the penalty area, and you should also keep the area free of unnecessary people and objects. Also, remember to wear a hard hat when working on the pulley system.

Another important safety precaution when working on a pulley system is to check the Safe Working Load (SWL) of the pulley before attaching anything. This will help you understand the maximum weight the pulley can hold. Also, consider the angle and height of the pulley system. Always use safety anchors and always remember to wear a hat when working on a pulley system.

Safe use of chain hoists requires training and experience. It is important to read the manufacturer's manual and follow all safety precautions. If you're not sure, you can actually inspect the hoist and look for signs of damage or tampering. Look for certifications for sprocket sets and other lifting accessories. Look for the Safe Working Load (SWL) marking on the chain hoist.

Example of a pulley system

Pulley systems are often used to lift items. It allows you to reduce the effort to lift and move the load by applying force in 1 direction. Pulley systems can be built and modeled to fit any type of project. This resource focuses on pulley systems and is designed to support the new GCSEs in Engineering, Design and Technology. There are also many examples of pulley systems suitable for various applications.

In the study, participants who read easy text took longer to manipulate the pulley system than those who read challenging text. In general, this suggests that participants with prior scientific experience used their cognitive abilities more effectively. Additionally, students who read simple texts spent less time planning the pulley system and more time on other tasks. However, the study did show that the time required to plan the pulley system was similar between the 2 groups.

In everyday life, pulley systems are used to lift various objects. Flagpoles are 1 of many pulley systems used to raise and lower flagpoles. They can also be used to raise and lower garage doors. Likewise, rock climbers use pulleys to help them ascend and descend. The pulley system can also be used to extend the ladder.

China best Agricultural Tractor 3 Point Hitch Powerful Lawn Hay Rotary Mower for Sale with Hot selling

Product Description

Agricultural tractor 3 point hitch powerful lawn hay rotary mower for sale

Tavol tractors are widely used for ploughing, harrow,rotary-cultivating, sowing, irrigation, spraying, harvesting and transportation etc. In paddy fields, dry land, arid land, orchard and plastic greenhouse.

We Cooperate with Domestic Well-known Brand Tractor Parts Suppliers, such as: Gearboxes are Assembled by Ourselves, the Gears Inside are Made of HangZhou Gears brand, the Bearings are HangZhou Brand, the Engines are Xichai, CZPT or YTO brand, and the Clutches are YTO ZC brand, the Hood and Cab is Equipped with Xihu (West Lake) Dis. Brand, and the Tires use HangZhou Or Xulun Brand etc.

Products range: 15hp-200hp Farm Tractors and Other Farm Machines

>>>>>>>>>Tavol 704 Tractor Specification<<<<<<<<<

| Tavol 70hp Tactor Main Parameters | ||

| Model | TL704 | |

| Machine parameters | Type | 4×4 |

| Rated Traction( KN) | 16.2 | |

| PTO Max Power (KW) | 43.8 | |

| Dimensions(mm) | 3560×1650×2350 | |

| Wheelbase(mm) | 1965 | |

| Track(mm) | Front wheel(mm) | 1150 |

| Rear wheel(mm) | 1200-1360 | |

| Ground clearance(mm) | Minimum ground clearance(mm) | 330 |

| Minimum turning cricle radius | Use unilateral braking | 2.85±0.20 |

| Not unilateral braking | 3.15±0.30 | |

| Minimum use quality | 1660 | |

| Gearbox | 8F+8R Shuttle Shift | |

| Steering System | hydraulic steering gear | |

| Drive Train | Clutch | double acting clutch |

| Working equipment | Maximum lifting force at 610mm(KN) | ≥10 |

| Suspension mechanism | Three-piont suspension type 1 | |

| PTO shaft | PTO Spedd(r/min) | 540/760(option: 540/1000) |

| Tire | Front wheel specifications | 6.00-16/6.5-16/7.5-16 |

| Rear wheel specifications | 9.5-24/11.2-24/12.4-24/12.4-28 | |

| Engine | Type | Inline, 4 stroke, Water cooled |

| Cylinder | 4 | |

| Optional | Cabin | AC/Heater |

| Roll bar | ||

| Canopy | ||

| Perfusion volume | Radiater(L) | 10 |

| Fuel tank(L) | 29 | |

| Engine oil pan(L) | 5 | |

| Driveline oil (L) | 20 | |

| Lifter(L) | 9.5 | |

| This parameter table is for reference only, everything is based on actual products | ||

>>>>>>>>>Tavol Company Profile<<<<<<<<<

Tavol Group is a High-tech Groups Companies, Which Engage in High-end Agricultural Equipment Manufacturing, Construction Machinery and High-precision Monitoring Sensors. CZPT Group is Located at the Foot of the World-famous Mountain HangZhou. Has Passed ISO9001, CE, SGS, BV, AAA, WIPO Madrid International Trademark, High-tech Enterprise Certification and Special Equipment Manufacturing License etc.

The Mission of CZPT Group is to Assemble the Best Tractors With the Best of Heart, and Strive for the SHangZhous of One billion Farmers; With the Values of Tolerance, Openness and Win-Win, Adopt Strict Production Technology and Inspection Standards, Select the Best Quality Brand Tractor Parts. To ensure a 100% Quality Standard, We will Independent Development and Production the Core Tractor Parts, Continue to Increase Investment in New Models and Technologies.

>>>>>>>>>Tavol tractor package<<<<<<<<<

High quality seaworthy package.

LCL is available. Optional CKD&SKD Package/ Full containers

>>>>>>>>>Why Choose Tavol<<<<<<<<<

>>>>>>>>>FAQ<<<<<<<<<

Q1:Are you the factory or the trading company?

A1:We are the factory,we located in CZPT City,ZheJiang Province,China.

Q2:What after-sales service can your company provide?

A2We can provide technical support and on-site installation support!

Q3:Can you provide spare parts for free?

A3:Of course.

Q4:Can you provide OEM?

A4:Yes,we can.

Q5:How about the delivery time?

A5:5-15 days according to the different quantity.

>>>>>>>>>Contact US<<<<<<<<<

Ms. Ellen Xiao(Sales Manager)

The 5 components of an axle, their function and installation

If you're considering replacing an axle in your vehicle, you should first understand what it is. It is the component that transmits electricity from 1 part to another. Unlike a fixed steering wheel, the axles are movable. The following article will discuss the 5 components of the half shaft, their function and installation. Hopefully you were able to identify the correct axle for your vehicle. Here are some common problems you may encounter along the way.

five components

The 5 components of the shaft are flange, bearing surface, spline teeth, spline pitch and pressure angle. The higher the number of splines, the stronger the shaft. The maximum stress that the shaft can withstand increases with the number of spline teeth and spline pitch. The diameter of the shaft times the cube of the pressure angle and spline pitch determines the maximum stress the shaft can withstand. For extreme load applications, use axles made from SAE 4340 and SAE 1550 materials. In addition to these 2 criteria, spline rolling produces a finer grain structure in the material. Cutting the splines reduces the strength of the shaft by 30% and increases stress.

The asymmetric length of the shaft implies different torsional stiffness. A longer shaft, usually the driver's side, can handle more twist angles before breaking. When the long axis is intact, the short axis usually fails, but this does not always happen. Some vehicles have short axles that permanently break, causing the same failure rate for both. It would be ideal if both shafts were the same length, they would share the same load.

In addition to the spline pitch, the diameter of the shaft spline is another important factor. The small diameter of a spline is the radius at which it resists twisting. Therefore, the splines must be able to absorb shock loads and shocks while returning to their original shape. To achieve these goals, the spline pitch should be 30 teeth or less, which is standard on Chrysler 8.75-inch and GM 12-bolt axles. However, a Ford 8.8-inch axle may have 28 or 31 tooth splines.

In addition to the CV joints, the axles also include CV joints, which are located on each end of the axle. ACV joints, also known as CV joints, use a special type of bearing called a pinion. This is a nut that meshes with the side gear to ensure proper shaft alignment. If you notice a discrepancy, take your car to a shop and have it repaired immediately.

Function

Axles play several important roles in a vehicle. It transfers power from the transmission to the rear differential gearbox and the wheels. The shaft is usually made of steel with cardan joints at both ends. Shaft Shafts can be stationary or rotating. They are all creatures that can transmit electricity and loads. Here are some of their functions. Read on to learn more about axles. Some of their most important features are listed below.

The rear axle supports the weight of the vehicle and is connected to the front axle through the axle. The rear axle is suspended from the body, frame and axle housing, usually spring loaded, to cushion the vehicle. The driveshaft, also called the propshaft, is located between the rear wheels and the differential. It transfers power from the differential to the drive wheels.

The shaft is made of mild steel or alloy steel. The latter is stronger, more corrosion-resistant and suitable for special environments. Forged for large diameter shafts. The cross section of the shaft is circular. While they don't transmit torque, they do transmit bending moment. This allows the drive train to rotate. If you're looking for new axles, it's worth learning more about how they work.

The shaft consists of 3 distinct parts: the main shaft and the hub. The front axle assembly has a main shaft, while the rear axle is fully floating. Axles are usually made of chrome molybdenum steel. The alloy's chromium content helps the axle maintain its tensile strength even under extreme conditions. These parts are welded into the axle housing.

Material

The material used to make the axle depends on the purpose of the vehicle. For example, overload shafts are usually made of SAE 4340 or 1550 steel. These steels are high strength low alloy alloys that are resistant to bending and buckling. Chromium alloys, for example, are made from steel and have chromium and molybdenum added to increase their toughness and durability.

The major diameter of the shaft is measured at the tip of the spline teeth, while the minor diameter is measured at the bottom of the groove between the teeth. These 2 diameters must match, otherwise the half shaft will not work properly. It is important to understand that the brittleness of the material should not exceed what is required to withstand normal torque and twisting, otherwise it will become unstable. The material used to make the axles should be strong enough to carry the weight of a heavy truck, but must also be able to withstand torque while still being malleable.

Typically, the shaft is case hardened using an induction process. Heat is applied to the surface of the steel to form martensite and austenite. The shell-core interface transitions from compression to tension, and the peak stress level depends on the process variables used, including heating time, residence time, and hardenability of the steel. Some common materials used for axles are listed below. If you're not sure which material is best for your axle, consider the following guide.

The axle is the main component of the axle and transmits the transmission motion to the wheels. In addition, they regulate the drive between the rear hub and the differential sun gear. The axle is supported by axle bearings and guided to the path the wheels need to follow. Therefore, they require proper materials, processing techniques and thorough inspection methods to ensure lasting performance. You can start by selecting the material for the shaft.

Choosing the right alloy for the axle is critical. You will want to find an alloy with a low carbon content so it can harden to the desired level. This is an important consideration because the hardenability of the alloy is important to the durability and fatigue life of the axle. By choosing the right alloy, you will be able to minimize these problems and improve the performance of your axle. If you have no other choice, you can always choose an alloy with a higher carbon content, but it will cost you more money.

Install

The process of installing a new shaft is simple. Just loosen the axle nut and remove the set bolt. You may need to tap a few times to get a good seal. After installation, check the shaft at the points marked "A" and "D" to make sure it is in the correct position. Then, press the "F" points on the shaft flange until the points are within 0.002" of the runout.

Before attempting to install the shaft, check the bearings to make sure they are aligned. Some bearings may have backlash. To determine the amount of differential clearance, use a screwdriver or clamp lever to check. Unless it's caused by a loose differential case hub, there shouldn't be any play in the axle bearings. You may need to replace the differential case if the axles are not mounted tightly. Thread adjusters are an option for adjusting drive gear runout. Make sure the dial indicator is mounted on the lead stud and loaded so that the plunger is at right angles to the drive gear.

To install the axle, lift the vehicle with a jack or crane. The safety bracket should be installed under the frame rails. If the vehicle is on a jack, the rear axle should be in the rebound position to ensure working clearance. Label the drive shaft assemblies and reinstall them in their original positions. Once everything is back in place, use a 2-jaw puller to pry the yoke and flange off the shaft.

If you've never installed a half shaft before, be sure to read these simple steps to get it right. First, check the bearing surfaces to make sure they are clean and undamaged. Replace them if they look battered or dented. Next, remove the seal attached to the bushing hole. Make sure the shaft is installed correctly and the bearing surfaces are level. After completing the installation process, you may need to replace the bearing seals.