Product Description

Hoist Lift Winch Crane Pushing Pulling Pressing Mixing Moving Helical Worm Right Angle Gear Speed Reducer

Product Description

1. Compact structure and simple assembly;

2. Wide speed ranges and high torque;

3. Low noise, good sealing performance, high efficiency;

4. Stable and safe, long lifetime, universal;

5. Multi-structure, various assembling methods

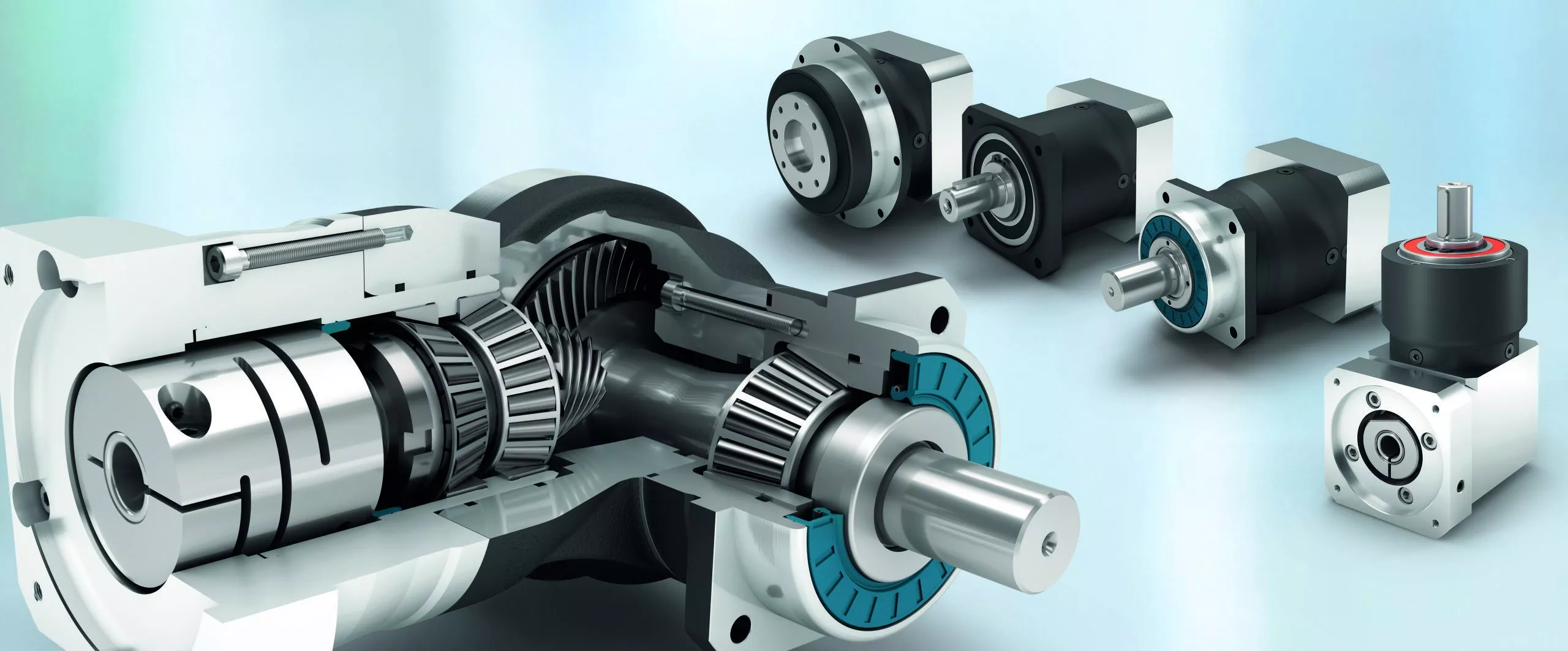

Detailed Photos

Related Product

Product Parameters

| ANG Helical Gear Reducer | |

| Model | R17 ~ 187, F37-177, K37-187, S37-97 |

| Input power | 0.06kw ~ 250kw |

| Input speed | 750rpm ~ 3000rpm |

| Reduction ratio | 1/1.3 ~ 1/27000 |

| Input motor | AC (1 phase or 3 phase) / DC / BLDC motor |

| Install type | Foot / CHINAMFG shaft / Hollow shaft / Output flange… |

| Efficiency | 94% ~ 98 % for R F K series |

| Material of housing | die-cast aluminum / Cast iron / Stainless steel |

| Precision of gear | Accurate grinding, class 6 |

| Heat treatment | Carburizing and quenching |

| Accessories | Brake / Flange / Motor adapter / Torque arm … |

Our Advantages

Company Profile

Certifications

FAQ

Q: Can you make the gear reducer with customization?

A: Yes, we can customize per your request, like oil, bearing, shaft size, flange, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What's your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, by sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | Order Sample Blue or Grey

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can gear reducers be customized for specific industrial needs and requirements?

Yes, gear reducers can be customized to meet specific industrial needs and requirements. Manufacturers offer customization options to ensure that gear reducers are tailored to the unique demands of various applications:

1. Gear Ratio Selection: Gear reducers can be designed with specific gear ratios to achieve the desired speed reduction or increase, catering to the specific requirements of the machinery or equipment.

2. Shaft Configurations: Gear reducers can be configured with different shaft sizes, lengths, and orientations to fit seamlessly into existing systems or accommodate specific mounting arrangements.

3. Torque Capacity: Customized gear reducers can be designed to handle higher or lower torque loads based on the application's operational requirements.

4. Environmental Considerations: Gear reducers can be customized with special coatings, materials, or seals to withstand harsh environments, extreme temperatures, or corrosive conditions.

5. Noise and Vibration Reduction: Custom designs can incorporate features to reduce noise and dampen vibrations, enhancing the overall operation and user experience.

6. Mounting and Connection Options: Manufacturers can adapt gear reducer designs to include specific mounting interfaces or connection methods that align with the equipment's design.

7. Lubrication and Maintenance: Customized gear reducers can include features for easy maintenance, such as accessible lubrication points or monitoring systems.

8. Integration with Controls: Gear reducers can be customized to integrate seamlessly with control systems, sensors, or automation processes, enhancing system efficiency and performance.

By collaborating with manufacturers and providing detailed specifications, industries can obtain tailor-made gear reducers that address their specific operational needs and contribute to the success of their applications.

What maintenance practices are essential for prolonging the lifespan of gear reducers?

Proper maintenance is crucial for extending the lifespan and ensuring optimal performance of gear reducers. Here are essential maintenance practices:

- 1. Lubrication: Regular lubrication of gear reducers is vital to reduce friction, wear, and heat generation. Use the recommended lubricant and follow the manufacturer's guidelines for lubrication intervals.

- 2. Inspection: Routinely inspect gear reducers for signs of wear, damage, or leaks. Check for unusual noises, vibrations, or temperature increases during operation.

- 3. Alignment: Ensure proper alignment of the input and output shafts. Misalignment can lead to increased wear, noise, and reduced efficiency. Align the components according to the manufacturer's specifications.

- 4. Cooling and Ventilation: Maintain proper cooling and ventilation to prevent overheating. Ensure that cooling fans and vents are clean and unobstructed.

- 5. Seal Maintenance: Inspect and replace seals as needed to prevent contaminants from entering the gear reducer. Contaminants can lead to accelerated wear and reduced performance.

- 6. Bolts and Fasteners: Regularly check and tighten bolts and fasteners to prevent loosening during operation, which can cause misalignment or component damage.

- 7. Replacing Worn Components: Replace worn or damaged components, such as gears, bearings, and seals, with genuine parts from the manufacturer.

- 8. Vibration Analysis: Conduct periodic vibration analysis to identify potential issues early. Excessive vibration can indicate misalignment or component wear.

- 9. Maintenance Records: Keep detailed maintenance records, including lubrication schedules, inspection dates, and component replacements. This helps track the history of the gear reducer and aids in future maintenance planning.

- 10. Training: Provide proper training to maintenance personnel on gear reducer maintenance and troubleshooting techniques.

By adhering to these maintenance practices, you can maximize the lifespan of your gear reducers, minimize downtime, and ensure reliable operation in your industrial processes.

Are there variations in gear reducer designs for specific tasks and applications?

Yes, gear reducer designs vary widely to suit specific tasks and applications across various industries. Manufacturers offer a range of gear reducer types and configurations to accommodate different requirements, including:

- Helical Gear Reducers: These are versatile and provide smooth and efficient torque transmission. They are commonly used in applications requiring high precision and moderate speed reduction, such as conveyors, mixers, and agitators.

- Bevel Gear Reducers: These are ideal for transmitting power between intersecting shafts. They are often used in heavy machinery, printing presses, and automotive applications.

- Worm Gear Reducers: These provide compact solutions and are suitable for applications with higher speed reduction requirements, such as conveyor systems, winches, and elevators.

- Planetary Gear Reducers: These offer high torque density and are used in applications demanding precise control, such as robotics, aerospace, and heavy-duty machinery.

- Parallel Shaft Gear Reducers: Commonly used in industrial machinery, these reducers are designed for high torque and reliability.

- Right-Angle Gear Reducers: These are used when space limitations require a change in shaft direction, commonly found in packaging equipment and conveyors.

Each type of gear reducer has unique features and benefits that make it suitable for specific tasks. Manufacturers often provide customization options to tailor gear reducers to the precise requirements of an application, including gear ratios, mounting options, and input/output configurations.

Therefore, the variation in gear reducer designs allows industries to select the most appropriate type based on factors such as torque, speed, space constraints, precision, and environmental conditions.

editor by CX 2024-03-29

China Professional Pad Series Electric High Output Gearbox Motor Gear Speed Reducer Servo Motor Gearbox best automatic gearbox

Product Description

Good Quality High Torque PAD Series Planetary Gearbox Speed Geared Reducer with Square Flange Output

PAD sereis flange output planetary reducer features compact structure and high precision. Compared with other general gearbox, the use of PAD enables the installation space to be saved. The compact structure performs high torsional rigidity, and the taper roller bearing support provides high axial and moment load capacity.

PAD planetary gearbox is suitable for motion transmission where high positioning precision is required, and other automatic fields like dynamic cyclic operations, CNC machines and robotic industry.

- Precision Grade:

P0 ( ≤ 1 arcmin, ≤ 3 arcmin )

P1 ( ≤ 3 arcmin, ≤ 5 arcmin )

P2 ( ≤ 6 arcmin, ≤ 8 arcmin )

- Service Life: 22000h

- Operating Temperature: -15ºC ~ +90ºC

- Protection Grade: IP65

- Mounting Position: Any Direction

- Efficiency: ≥ 94% ~ ≥ 97%

Product Parameters

Detailed Photos

14 types of speed building ratio:=4-100

Minimum return interval: P0, P1P2

Maximum output torque: 23N. m-650N. m

Extremely high torsional rigidity and excellent performance

The highest load free policy is used in conditions with extremely high bearing capacity

Optimize power transmission and increase efficiency line by 98%

Very quiet during operation

Lifetime lubrication, no push protection

Fully sealed, IP65 protection level

Shortest structure and flexible installation

Small model: 64.90.110.140

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% - 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Handling Sudden Changes in Direction and Speed with Servo Gearboxes

Servo gearboxes are designed to handle sudden changes in direction and speed effectively, ensuring precise motion control even during dynamic operations. They employ several mechanisms to address these challenges:

1. Acceleration and Deceleration Profiles: Servo systems can be programmed with specific acceleration and deceleration profiles. This means that when a sudden change in speed or direction is commanded, the system can ramp up or down the speed smoothly, reducing the impact of sudden changes on the mechanical components.

2. Closed-Loop Control: Servo systems operate in a closed-loop configuration, where feedback sensors continuously monitor the actual position and speed of the system. When a sudden change is commanded, the controller can make real-time adjustments to ensure the system reaches the desired position accurately and smoothly.

3. Torque Control: Servo gearboxes are designed to provide high torque output even at low speeds. This is crucial for handling sudden changes in direction and speed, as the gearbox can deliver the required torque to quickly accelerate or decelerate the load.

4. Dynamic Response: Servo systems have fast dynamic response capabilities, which means they can quickly adapt to changes in input commands. This responsiveness allows the system to handle sudden changes in direction and speed without sacrificing accuracy or stability.

5. Electronic Damping: Some advanced servo systems incorporate electronic damping mechanisms that can be adjusted based on the application's requirements. This feature helps dampen vibrations and oscillations that may occur during sudden changes in motion.

6. Overcurrent and Overvoltage Protection: Servo systems are equipped with protection mechanisms that detect excessive currents or voltages. If a sudden change in direction or speed causes abnormal loads or voltages, the system can take corrective actions to prevent damage.

Overall, servo gearboxes excel in handling sudden changes in direction and speed by leveraging their closed-loop control, high torque output, and fast dynamic response capabilities. These features allow them to provide accurate and reliable motion control in dynamic and rapidly changing operating conditions.

Real-World Examples of Products Using Servo Gearboxes

Servo gearboxes find application in various industries and products, contributing to their precision, efficiency, and performance:

- Industrial Robots: Industrial robots utilize servo gearboxes to achieve precise and controlled movements, enabling tasks such as assembly, welding, and material handling.

- CNC Machines: Computer Numerical Control (CNC) machines use servo gearboxes for accurate positioning and control of cutting tools, resulting in high-quality and complex machining operations.

- Automated Packaging Machines: Servo gearboxes play a vital role in packaging machines by ensuring precise filling, sealing, and labeling of products, leading to consistent packaging quality.

- Medical Devices: Advanced medical devices like robotic surgical systems use servo gearboxes to provide surgeons with precise control and dexterity during minimally invasive procedures.

- Textile Machinery: Servo gearboxes are employed in textile machinery to control the movement of yarn, ensuring uniform and high-quality fabric production.

- Automated Material Handling Systems: Servo gearboxes enable automated conveyors, lifts, and sorting systems to handle materials efficiently and accurately in warehouses and distribution centers.

- Printers and Plotters: High-resolution printers and plotters use servo gearboxes to precisely position print heads and ensure accurate image reproduction.

- Food Processing Equipment: Servo gearboxes are integrated into food processing machines for tasks like slicing, portioning, and mixing, ensuring consistent product quality and yield.

- Pharmaceutical Manufacturing: Pharmaceutical machinery relies on servo gearboxes for precise dosage and filling operations, crucial for drug production.

- Aerospace Components: Aerospace systems, such as landing gear mechanisms and control surfaces, use servo gearboxes to achieve precise movement and ensure the safety of flight.

These examples demonstrate the widespread adoption of servo gearboxes across various industries, where precision, accuracy, and controlled motion are critical for efficient and high-performance operations.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by CX 2024-03-28

China high quality Sw030 Sw040 Sw050 Sw063 Sw075 Sw090 Sw Vf Speed Reducer Gear Box Unit Worm Gearbox with Great quality

Product Description

VF030 VF040 VF050 VF063 VF075 VF090 VF110 VF130 VF150 SW030 SW040 SW050 SW063 SW075 SW090 Electrical Motor VF Speed Reducer Gear Box Unit Reductor Worm Gearbox

Product Description

1. Light in weight and non-rusting

2. Smooth in running, can work a long time in dreadful conditions

3. High efficiency, low noise

4. Good-looking in appearance, durable in service life, and small in volume

Detailed Photos

Product Parameters

| Model | 030 ~ 150 |

| Power | 0.06kw ~ 15kw |

| Input speed | 750rpm ~ 2000rpm |

| Reduction ratio | 1/5 ~ 1/100 |

| Input motor | AC (1 phase or 3 phase) / DC / BLDC / Stepper / Servo |

| Output shaft | Solid shaft / Hollow shaft / Output flange… |

| Dimension standard | Metric size / Inch size |

| Material of housing | die-cast aluminum / Cast iron / Stainless steel |

| Accessories | Flange / CZPT shaft / Torque arm / Cover … |

Product dimension

Our Advantages

Company Profile

FAQ

Q: Can you make the gearbox with customization?

A: Yes, we can customize per your request, like flange, shaft, configuration, material, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What's your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, and we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Blue or Silver

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Choosing the Right Agricultural Gearbox

There are a number of different types of agricultural gearboxes available. Some are Bevel, while others are Shaft-mounted, bearing-mounted, or CZPT gearboxes. To learn more about these different types, read on. We'll explain how each works and what to look for in an agricultural gearbox. Alternatively, you can search for information on each type on the web. Agricultural gearboxes can be a great option for your next project.

Bevel gearboxes

Bevel gearboxes are a type of mechanical transmission system that uses enclosed spiral and straight bevel-gears to transmit rotational power. They are typically mounted on a right-angle shaft and have a wide range of horsepower and ratios. Some bevel gearboxes are designed to be installed at varying angles. For example, CZPT Gearbox provides bevel gear drives for portable grain augers, elevators, and carts.

Bevel gearboxes are the most common type of gearbox. They have a single-stage design and the beveled edges of two gears interlock to transfer torque and rotation. Bevel gearboxes have multiple advantages over other types of gearboxes. They are also more cost-effective, run quietly, and produce less transmittable torque. They are designed to be used in low-torque applications.

A right-angle gearbox is used for a variety of agricultural applications. It is well-suited for use with offset rotary fillers and hollow output shafts. It has a reduction ratio of 2.44:1. The gearbox is built with a cast-iron case and can produce power rates up to 49kW. These bevel gearboxes are used in small agricultural work, including crop treatment, soil preparation, and cement mixers.

Spiral and straight bevel gears have two major benefits. The first is more durable, while the latter is quieter. Both types have their advantages and disadvantages. Bevel gears can be noisy, so they may not be the best choice for your equipment. But the latter has many benefits. The Spiral bevel gear has a high degree of total coverage, but it costs more to produce.

Shaft-mounted

Shaft-mounted agricultural gearboxes are designed for conveyer systems. These devices have interchangeable mounting dimensions with CZPT and CZPT gearboxes. Agricultural gearboxes are critical to the entire food chain. Worn gears can cause significant loss to farmers. As a result, it is essential to purchase high-quality gearboxes for your farm equipment. The following are some tips to choose the right gearbox for your needs.

Agricultural tractors include an internal combustion engine 10 and a speed change gearbox. The engine's cylinder block is mounted on the gearbox casing. The gearbox casing extends under the driver's position and has an elongated shape in the longitudinal direction. The gearbox casing is connected to the rear axle casing 15 by a connecting shaft. The shafts are designed to engage and disengage in opposite directions.

The mounting position of the gearbox is an important consideration. Some applications require no foundation for the gear drive. Generally, a shaft-mounted agricultural gearbox can be attached to the drive equipment via a low-speed shaft. In addition, the shaft is secured around a solid shaft. Rigid flange couplings may be used to connect the gear drive and driven equipment. This type of mounting is preferred for applications where there is no foundation.

Shaft-mounted agricultural gearboxes are designed to optimize machine performance. CZPT Gearbox Company is an innovative company that manufactures top-quality gear drives for a variety of agricultural machinery. They can reverse engineer existing designs or create custom gearboxes for your farm machinery. These agricultural gearboxes are designed to help farmers optimize their machines for maximum efficiency. They transmit power from the input shaft to the output shafts and facilitate change of speed, direction, and rotation.

Shaft-mounted with bearings

If you are looking to buy an agricultural gearbox, it will be beneficial to look at the different types of shaft-mounted gearboxes available. Shaft-mounted gearboxes are often made of steel, and are commonly constructed with AGMA class 12 gearing. They typically utilize tapered roller bearings on all shafts, and have a patented triple seal system that prevents dirt and moisture from getting inside. Additionally, they are easy to install and remove, as they don't require any tools. Finally, they are built to last with minimal maintenance, and will provide maximum uptime.

Shaft-mounted agricultural gearboxes are generally made of steel, and are available in both cylindrical and square shapes. Some types of shafts are able to rotate axially within the bearing while maintaining radial load carrying capabilities. Despite the differences in the shapes of these shafts, they offer high levels of efficiency and performance. For example, the Float-A-Shaft(r) 3 to 2 right-angle gearbox can accommodate both round and square-base mounting, and is capable of generating up to 1100 in-lbs of torque.

Shaft-mounted agricultural gearboxes are constructed from two types of roller bearings: cylindrical roller bearings and tapered roller bearings. A cylindrical roller bearing has one row of balls that are enclosed within a cage, and it has a single axis. The other two rows of bearings have a single or double-row arrangement. Both of them have high axial rigidity and can handle high axial loads.

CZPT gearboxes

The demand for food has skyrocketed since the turn of the century, and the World Bank estimates that the number of people on the planet will grow by 80 million annually by 2025. As the demand for food grows, agricultural machinery manufacturers are coming up with innovative ways to make the most of their land. This results in shorter cropping cycles and greater wear and tear on farm equipment, including CZPT agricultural gearboxes.

Bevel gearboxes are enclosed straight or spiral gears that transmit rotational power to various parts of agricultural machinery. They are available in a variety of right-angle and spiral configurations. The CZPT Gearbox, for example, features a 68-degree bevel gear drive for augers and grain carts. The company also offers a 50-degree bevel gear drive. These gearboxes are made with the latest technology and incorporate horizontally split housing designs.

Agricultural gearboxes from CZPT are available in a variety of designs, including reversing gears. Reversing gears feature ball bearings that reduce friction and increase efficiency. This gearbox can be purchased in a wide range of power ratings and blade counts, allowing the farmer to choose the one that works best for their needs. This will ensure long-term functionality and effectiveness. So whether you're a farmer or a manufacturer of agricultural equipment, a CZPT agricultural gearbox will work for you.

Bevel gearboxes with bearings

The bevel gearing is a popular choice for agricultural gearboxes due to its high load capacity. The bevel gearing is widely used in mechanical transmission systems, including agricultural tractors. For modern harvesters, high-performance gearboxes are necessary for smooth operation. Leading agricultural equipment manufacturers rely on CZPT Gearbox Company to provide these high-quality and durable drive systems. This is why we supply bevel gearboxes for agricultural machinery.

A bevel gearbox can be either straight or helical. The latter option is the simplest type and tends to be cheaper to produce. However, it is difficult to realize small profile coverage with straight gearwheels. Furthermore, it is less efficient in transmitting torque. The bevel gearbox can be used for both clockwise and counterclockwise rotation. It is available with a standard mount and aluminum casing.

Depending on the type of agriculture machinery, bevel gearboxes with bearings are suitable for many tasks. Their versatility allows them to be used in a variety of mechanical applications. The double gear allows the upper bevel gear angular gear 2 to pivot relative to the lower bevel gear angular gear 3.

Besides bearings, other factors influence the performance of agricultural gearboxes. Insufficient data may make it difficult to obtain the exact gear. For this reason, a broken gear requires a detailed manufacturing drawing. This drawing requires expertise in technical gear, as well as specialized engineering manpower. It also increases the cost of production. The gears are subjected to heat treatment before being shipped to the customer.

Bevel gearboxes with CZPT gearboxes

The demand for agricultural products has increased dramatically since 2010. The world population is increasing at a rapid pace (80 million people per year until 2025), but land is not. Farmers are looking for ways to maximize their land's potential to grow more food. This increased demand for agricultural machinery is driving the need for highly efficient gearboxes. With replacement parts easily available, manufacturers can meet the growing demand for agricultural equipment.

editor by CX 2024-03-26

China OEM K series spiral bevel helical speed Gearbox S series F series R series gear speed reducer bevel gearbox

Product Description

| Model Number | K series spiral bevel helical speed reducer | Structure Type | K KA KF KAF KAZ KAT KAB |

| Assembly Method | 1-6 | Input power | 0.18-180W |

| Enamelled Wire: | 100% Copper Wire | Reducer body | Steel |

| Ratio | 0.18-180W | Brand | FOX MOTOR |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Bending Machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal or Vertical |

| Layout: | Spiral bevel gear reducer |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 99/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do gear reducers enhance the efficiency of conveyor systems and robotics?

Gear reducers play a significant role in improving the efficiency of both conveyor systems and robotics by optimizing speed, torque, and control. Here's how they contribute:

Conveyor Systems:

In conveyor systems, gear reducers enhance efficiency in the following ways:

- Speed Control: Gear reducers allow precise control over the rotational speed of conveyor belts, ensuring that materials are transported at the desired speed for efficient production processes.

- Torque Adjustment: By adjusting gear ratios, gear reducers provide the necessary torque to handle varying loads and prevent overloading, minimizing energy wastage.

- Reverse Operation: Gear reducers enable smooth bidirectional movement of conveyor belts, facilitating tasks such as loading, unloading, and distribution without the need for additional components.

- Synchronization: Gear reducers ensure synchronized movement of multiple conveyor belts in complex systems, optimizing material flow and minimizing jams or bottlenecks.

Robotics:

In robotics, gear reducers enhance efficiency through the following means:

- Precision Movement: Gear reducers provide precise control over the movement of robot joints and arms, enabling accurate positioning and manipulation of objects.

- Reduced Inertia: Gear reducers help reduce the inertia experienced by robotic components, allowing for quicker and more responsive movements while conserving energy.

- Compact Design: Gear reducers offer a compact and lightweight solution for achieving various motion profiles in robotic systems, allowing for efficient use of space and resources.

- Torque Amplification: By amplifying torque from the motor, gear reducers enable robots to handle heavier loads and perform tasks that require greater force, enhancing their overall capabilities.

By providing precise speed control, torque adjustment, and reliable motion transmission, gear reducers optimize the performance of conveyor systems and robotics, leading to improved efficiency, reduced energy consumption, and enhanced operational capabilities.

Can gear reducers be used for both speed reduction and speed increase?

Yes, gear reducers can be utilized for both speed reduction and speed increase, depending on their design and arrangement. The functionality to either decrease or increase rotational speed is achieved by altering the arrangement of gears within the gearbox.

1. Speed Reduction: In speed reduction applications, a gear reducer is designed with gears of different sizes. The input shaft connects to a larger gear, while the output shaft is connected to a smaller gear. As the input shaft rotates, the larger gear turns the smaller gear, resulting in a decrease in output speed compared to the input speed. This configuration provides higher torque output at a lower speed, making it suitable for applications that require increased force or torque.

2. Speed Increase: For speed increase, the gear arrangement is reversed. The input shaft connects to a smaller gear, while the output shaft is connected to a larger gear. As the input shaft rotates, the smaller gear drives the larger gear, resulting in an increase in output speed compared to the input speed. However, the torque output is lower than that of speed reduction configurations.

By choosing the appropriate gear ratios and arrangement, gear reducers can be customized to meet specific speed and torque requirements for various industrial applications. It's important to select the right type of gear reducer and configure it correctly to achieve the desired speed reduction or speed increase.

What are the benefits of using a gear reducer in industrial applications?

Gear reducers offer several benefits that make them indispensable in various industrial applications:

1. Speed Reduction: Gear reducers allow the reduction of high-speed input from motors or engines to lower, more usable output speeds for specific applications, ensuring proper equipment operation and safety.

2. Torque Increase: By leveraging the mechanical advantage of gear ratios, gear reducers can significantly increase torque output, enabling the handling of heavy loads and providing the necessary power for tasks such as lifting, conveying, and processing.

3. Precise Control: Gear reducers enable fine-tuning of rotational speed and torque, providing precise control over machinery and processes, which is crucial in industries like manufacturing, material handling, and robotics.

4. Shock Load Absorption: Gear reducers can absorb and dampen sudden shocks or changes in load, protecting both the machinery and connected components from abrupt forces that could otherwise lead to damage.

5. Versatility: With various gear types (e.g., spur, helical, worm) and designs, gear reducers can be tailored to different applications, including those requiring specific speed ratios, torque ranges, and environmental conditions.

6. Efficient Power Transmission: Gear reducers offer high mechanical efficiency, minimizing energy loss during power transmission, which is especially valuable in energy-conscious industries.

7. Compact Design: Gear reducers provide a compact solution for transmitting power and adjusting speeds, making them suitable for installations with space constraints.

8. Reliability and Longevity: Well-designed and properly maintained gear reducers can offer extended service life, contributing to reduced downtime and maintenance costs.

Overall, gear reducers enhance the performance, efficiency, and reliability of industrial equipment, making them essential components in a wide range of applications across various industries.

editor by CX 2024-03-14

China supplier Pl80 NEMA32 Speed Reducer High Precision Planetary Gearbox for 80mm Servo Motor Ratio gearbox design

Product Description

China made PL80 nema32 speed reducer High Precision planetary gearbox for 80mm servo motor ratio 3/5/10

The deceleration ratio is 3/4/5/7/10/12/16/20/25/28/35/40/50/70/80/100/140/175/200/250/280/350/400/500/700/1000 large spot inventory reduction ratio! Provide custom other spec reducer and deceleration ratio! No matter the quantity as long as you can provide drawings we can make it!

| KeyWords | Planetary gearbox |

| Model | PL80 |

| Ratio | 1-stage: 3/4/5/7/10

2-stage: 12/16/20/25/28/35/40/50/70 3-stage: 80/100/140/175/200/250/280/350/400/500/700/1000 |

| Color | Black/Silver or on customer request |

| Oil Seal | Input: SKF Output: NAK |

| Lubricant | Synthetic or Mineral Oil |

| Warranty | 1 year |

| Packing | Carton and wooden case |

| Mass | 2.5Kg |

Get a discount

| product assortment |

Click to get your special discount

| Service |

Customer service officer

Our customer service personnel are experienced product specialists who can answer your questions 7 days a week from 9 am to 5 pm. Contact us now. |

OEM / ODMOur professional staffs allow us to have the capability to design and manufacture a wide range of new items according to the buyer's requirements. Our ability to provide buyers labels and design services for our clients make us an attractive choice. |

Firm teamTimes Brilliant is committed to delivery quality products. We guarantee our products to be free from manufacture defects. We offer one-month of return & exchange service, one-year of parts replacement and lifetime tech support |

| Factory Tour |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Soft Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

High-Speed Applications and Accuracy in Servo Gearboxes

Servo gearboxes can indeed be used in high-speed applications without compromising accuracy, thanks to their design features:

1. Precision Engineering: Servo gearboxes are engineered with high precision, which allows them to maintain accurate motion control even at high speeds.

2. Reduced Backlash: Many servo gearbox designs incorporate mechanisms to minimize backlash, which is the lost motion between input and output. This feature enhances accuracy even in high-speed scenarios.

3. Advanced Bearings: High-quality bearings used in servo gearboxes reduce friction and contribute to maintaining accuracy and efficiency at high speeds.

4. Rigid Construction: The rigid construction of servo gearboxes minimizes flexing or deformation under high-speed loads, ensuring that the intended motion is accurately transmitted.

5. Dynamic Balancing: Some servo gearboxes are dynamically balanced to minimize vibrations that could affect accuracy during high-speed operation.

6. Lubrication: Proper lubrication practices play a vital role. The right lubricant minimizes friction, heat, and wear, ensuring accuracy even at high speeds.

7. Feedback Systems: High-speed applications often use feedback systems, such as encoders, to constantly monitor and adjust the positioning. This further enhances accuracy.

8. Advanced Control Algorithms: The combination of accurate gearboxes and advanced control algorithms ensures precise motion profiles even at high speeds.

Overall, servo gearboxes are designed to excel in accuracy, precision, and efficiency, making them suitable for high-speed applications where maintaining accuracy is crucial.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.

3. Dynamic Response: Servo gearboxes are designed for high dynamic response, meaning they can quickly adjust their speed and torque based on the controller's commands. This responsiveness allows for rapid and smooth changes in speed and direction without sudden jerks or jolts.

4. Programmable Profiles: Many servo systems offer the capability to program acceleration and deceleration profiles. Engineers can define specific acceleration and deceleration curves tailored to the application's requirements. These profiles ensure that the machinery achieves the desired speed changes gradually and smoothly.

5. Reduced Wear and Tear: The controlled and gradual acceleration and deceleration provided by servo gearboxes reduce the wear and tear on mechanical components. Sudden changes in speed can lead to shock loads and vibration, potentially damaging the machinery. Servo gearboxes help mitigate these effects, extending the lifespan of components.

6. Increased Productivity: Smooth acceleration and deceleration reduce the chances of product damage, improve product quality, and enhance the overall efficiency of the process. This is particularly important in applications where precise motion control is critical.

Overall, servo gearboxes contribute to the seamless acceleration and deceleration of machinery by providing accurate control, dynamic responsiveness, and programmable motion profiles. These features ensure that machinery can achieve the desired speed changes while maintaining precision, efficiency, and longevity.

Role of Servo Gearbox in Robotics and Automation

Servo gearboxes play a crucial role in enhancing the performance and precision of robotics and automation systems:

1. Precision Motion Control: In robotics and automation, precise control of movement is essential. Servo gearboxes provide accurate speed and position control, allowing robots to perform intricate tasks with high accuracy.

2. Efficient Power Transmission: Servo gearboxes efficiently transmit power from the motor to the robotic components, ensuring minimal energy loss and optimizing the overall system efficiency.

3. Dynamic Performance: Robots often require quick changes in direction, speed, and acceleration. Servo gearboxes excel in dynamic performance, enabling rapid adjustments and smooth motion changes.

4. Reducing Backlash: Backlash in gear systems can lead to imprecise movements. Servo gearboxes are designed to minimize backlash, resulting in accurate positioning and reduced lost motion.

5. Compact Design: Many robotic applications require compact and lightweight components. Servo gearboxes offer a high torque-to-size ratio, allowing robots to generate significant power while maintaining a small footprint.

6. Smooth and Silent Operation: The low backlash and precise gearing of servo gearboxes contribute to smooth and quiet operation, which is crucial in environments where noise and vibration can affect performance.

7. Feedback Integration: Servo gearboxes can integrate with various feedback devices, such as encoders, resolvers, and sensors, to provide accurate position and speed information to the control system.

8. Reliable and Repeatable Performance: The consistent and repeatable performance of servo gearboxes ensures that robots can execute tasks accurately and reliably over time.

9. Customization: Servo gearboxes can be customized to meet the specific requirements of different robotic applications, including factors like gear ratios, mounting options, and feedback compatibility.

10. Versatility: From industrial assembly lines to medical robotics, servo gearboxes find applications in a wide range of industries, contributing to improved automation and efficiency.

In summary, the role of a servo gearbox in robotics and automation is to provide the precise and efficient motion control necessary for robots to perform tasks with accuracy, speed, and reliability.

editor by CX 2024-03-14

China wholesaler Helical Gear Speed Reducer TXT2-10 car gearbox

Product Description

SMRY Reducer Specification

1 Twin Tapered Output Hub

A tapered bore in both sides of the reducer's output hub snugs up against a matching taper on the outer surface of the bushing. Bushing mounting screws pass through the bushingflange into a mounting collar on the hub. As the screws are tightened, the bushing moves inward, gripping the driven machine's input shaft tightly and evenly around every pointon its circumference. It is easy-on, easy-off. All the Output Bushing Bore accord to ANSI

2 Precrisio. n High Qua lity Gearing

C ompu ter D e s i g n He lical .Gears, Strong Alloy Materials for High Load Capacity, Case Carburized for long life, Ground Profile CHINAMFG tooth Profile, In

Conformance with ISO 1328-1997, 98% Efficiency for Per Stage, Smooth Quiet Operation with Several Teeth in Mesh.

3 Maximum Capacity Housing Design

Close Grain Cast Iron Construction, Excellent Vibration Dampening & Shock Resistance Features, Precision Bored and Dowelled to Ensure Accurate In-Line Assembly.

4 Strong Alloy Steel Shafts

Strong Alloy Steel, Hardened, Ground on Journals, Gear Seatings and Extensions,for Maximum Load and Maximum Torsional Loads. Generous Size Shaft

Keys for Shock Loading .

5 Use adapter for mount the torque arm, increase the strength of the gear case, the torque armeasy-on and easy-off and reliability, controls position of standard torque arm mounting within recommended limits.

6 BackStops

Alternative Parts, anti-run back device, are available on all 15:1 and 25:1 ratio units.

7 Bearings and Oilseals

Bearings are all tapered roll bearings(Except SMRY-2), have long time service time. Oilsealsare Double Lipped Garter Spring Type, Ensuring Effective Oil

Sealing.

8 Torque Arm Assembly

For Easy Adjustment of the Belt.

| size | Nominal ratio 15:1 | Nominal ratio 25:1 | weight lbs |

||||

| Actual Ratio | Maximum Input rpm | Maximum Ouput rpm | Actual Ratio | Maximum Input rpm | Maximum Ouput rpm | ||

| SMRY-2 | 14.04 | 1974 | 140 | 23.37 | 1994 | 85 | 58 |

| SMRY-3 | 14.87 | 2083 | 140 | 24.75 | 2100 | 85 | 98 |

| SMRY-4 | 15.13 | 2118 | 140 | 24.38 | 2072 | 85 | 139 |

| SMRY-5 | 15.4 | 1925 | 125 | 25.56 | 2044 | 80 | 207 |

| SMRY-6 | 15.34 | 1916 | 125 | 25.14 | 2571 | 80 | 285 |

| SMRY-7 | 15.23 | 1827 | 120 | 24.84 | 1863 | 75 | 462 |

| SMRY-8 | 15.08 | 1809 | 120 | 24.62 | 1847 | 75 | 633 |

| SMRY-9 | 15.12 | 1814 | 120 | 25.66 | 1925 | 75 | 760 |

size SMRY-2, 3,4,5,6,7,8,9 , ratio 15:1 ,25:1

SMRY Shafted mounted gear speed reducer:

1) Shafted mounted gear unit for conveyer systems

2) All gears are heat treated and fixed to achieve low noise and high output

3) Mounting dimensions are interchangeable with Fener

Company Profile

l The largest manufacturer and exporter of worm gear reducers in Asia.

l Established in 1976, we transformed from a county owned factory to private 1 in 1996. HangZhou SINO-DEUTSCH POWER TRANSMISSION EQUIPMENT CO.,LTD is our new name since 2001.

l We are the first manufacturer of reducers and gearboxes in China who was given export license since year 1993.

l "Fixedstar" brand gearboxes and reducers are the first owner of CHINA TOP BRAND and Most Famous Trade Mark for reducers.

First to achieve ISO9001 and CE Certificate among all manufacturers of gearboxes in China.

As a professional manufacturer of worm gearbox and worm gear reducers in China, we mainly produce reduction gearbox,aluminum case worm gearboxes,arc gear cylindrical worm gearboxes, worm gear reducers, in line helical gearboxes, and cyclo drive reducers, etc. These products feature rational structure, stable performance, and reliable quality, and so on. They are widely used in power, mining, metallurgy, building material, chemical, food, printing, ceramic, paper-making, tobacco, and other industries.

We have 600 workers in our factory, which covers 70,000 square CHINAMFG in HangZhou. We have been making 2,500 units of reducers everyday since 2012. We are proudly exporting 70% of our products to more than 40 countries all over the word. Our customers come from Italy, Germany, USA, Canada, Spain, UK, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial countries in the world. 30% of them are OEM made for direct manufacturers of other products.

We warmly welcome customers from other parts of the world to visit us. Seeing is believing. We are very confident that after visiting our facility, you will have confidence on our products. We have the latest automatic equipments and experienced workers to ensure the stable quality and large output. We have the most sophisticated technical and engineering team to support most demanding requirement on standard and OEM products.

Looking CHINAMFG to meeting you in HangZhou, China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Marine, Industry |

|---|---|

| Function: | Speed Reduction |

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Material: | Cast Iron |

| Manipulate Way: | Semi-Automatic Manipulation |

| Customization: |

Available

| Customized Request |

|---|

How do gear reducers contribute to energy efficiency in machinery and equipment?

Gear reducers play a significant role in enhancing energy efficiency in various machinery and equipment. Here's how they contribute:

1. Speed Reduction: Gear reducers are commonly used to reduce the speed of the input shaft, allowing the motor to operate at a higher speed where it's most efficient. This speed reduction helps match the motor's optimal operating range, reducing energy consumption.

2. Torque Increase: Gear reducers can increase torque output while decreasing speed, enabling machinery to handle higher loads without the need for a larger, more energy-intensive motor.

3. Matching Load Requirements: By adjusting gear ratios, gear reducers ensure that the machinery's output speed and torque match the load requirements. This prevents the motor from operating at unnecessary high speeds, saving energy.

4. Variable Speed Applications: In applications requiring variable speeds, gear reducers allow for efficient speed control without the need for continuous motor adjustments, improving energy usage.

5. Efficient Power Transmission: Gear reducers efficiently transmit power from the motor to the load, minimizing energy losses due to friction and inefficiencies.

6. Motor Downsizing: Gear reducers enable the use of smaller, more energy-efficient motors by converting their higher speed, lower torque output into the lower speed, higher torque needed for the application.

7. Decoupling Motor and Load Speeds: In cases where the motor and load speeds are inherently different, gear reducers ensure the motor operates at its most efficient speed while still delivering the required output to the load.

8. Overcoming Inertia: Gear reducers help overcome the inertia of heavy loads, making it easier for motors to start and stop, reducing energy consumption during frequent operation.

9. Precise Control: Gear reducers provide precise control over speed and torque, optimizing the energy consumption of machinery in processes that require accurate adjustments.

10. Regenerative Braking: In some applications, gear reducers can be used to capture and convert kinetic energy back into electrical energy during braking or deceleration, improving overall energy efficiency.

By efficiently managing speed, torque, and power transmission, gear reducers contribute to energy-efficient operation, reducing energy consumption, and minimizing the environmental impact of machinery and equipment.

How do gear reducers ensure efficient power transmission and motion control?

Gear reducers play a vital role in ensuring efficient power transmission and precise motion control in various industrial applications. They achieve this through the following mechanisms:

- 1. Speed Reduction/Increase: Gear reducers allow you to adjust the speed between the input and output shafts. Speed reduction is essential when the output speed needs to be lower than the input speed, while speed increase is used when the opposite is required.

- 2. Torque Amplification: By altering the gear ratio, gear reducers can amplify torque from the input to the output shaft. This enables machinery to handle higher loads and provide the necessary force for various tasks.

- 3. Gear Train Efficiency: Well-designed gear trains within reducers minimize power losses during transmission. Helical and spur gears, for example, offer high efficiency by distributing load and reducing friction.

- 4. Precision Motion Control: Gear reducers provide precise control over rotational motion. This is crucial in applications where accurate positioning, synchronization, or timing is required, such as in robotics, CNC machines, and conveyor systems.

- 5. Backlash Reduction: Some gear reducers are designed to minimize backlash, which is the play between gear teeth. This reduction in play ensures smoother operation, improved accuracy, and better control.

- 6. Load Distribution: Gear reducers distribute the load evenly among multiple gear teeth, reducing wear and extending the lifespan of the components.

- 7. Shock Absorption: In applications where sudden starts, stops, or changes in direction occur, gear reducers help absorb and dampen shocks, protecting the machinery and ensuring reliable operation.

- 8. Compact Design: Gear reducers provide a compact solution for achieving specific speed and torque requirements, allowing for space-saving integration into machinery.

By combining these principles, gear reducers facilitate the efficient and controlled transfer of power, enabling machinery to perform tasks accurately, reliably, and with the required force, making them essential components in a wide range of industries.

How do gear reducers handle variations in input and output speeds?

Gear reducers are designed to handle variations in input and output speeds through the use of different gear ratios and configurations. They achieve this by utilizing intermeshing gears of varying sizes to transmit torque and control rotational speed.

The basic principle involves connecting two or more gears with different numbers of teeth. When a larger gear (driving gear) engages with a smaller gear (driven gear), the rotational speed of the driven gear decreases while the torque increases. This reduction in speed and increase in torque enable gear reducers to efficiently adapt to variations in input and output speeds.

The gear ratio is a critical factor in determining how much the speed and torque change. It is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. A higher gear ratio results in a greater reduction in speed and a proportionate increase in torque.

Planetary gear reducers, a common type, use a combination of gears including sun gears, planet gears, and ring gears to achieve different speed reductions and torque enhancements. This design provides versatility in handling variations in speed and torque requirements.

In summary, gear reducers handle variations in input and output speeds by using specific gear ratios and gear arrangements that enable them to efficiently transmit power and control motion characteristics according to the application's needs.

editor by CX 2024-03-06

China Professional Customizable High Precision Harmonic Drive/High Precision Harmonic Drive Strain Wave Gear Robot Gearbox/Hamonic Speed Reducer cvt gearbox

Product Description

Product Description:

1. Flexspline is a hollow flanging standard cylinder structure.

2. There is a large-diameter hollow shaft hole in the middle of the cam of the wave generator. The internal design of the reducer has a support bearing.

3. It has a fully sealed structure and is easy to install. It is very suitable for occasions where the wire needs to be threaded from the center of the reducer.

Advantages:

1. High precision,high torque

2. Dedicated technical personnel can be on-the-go to provide design solutions

3. Factory direct sales fine workmanship durable quality assurance

4. Product quality issues have a one-year warranty time, can be returned for replacement or repair

Company profile:

HangZhou CHINAMFG Technology Co., Ltd. established in 2014, is committed to the R & D plant of high-precision transmission components. At present, the annual production capacity can reach 45000 sets of harmonic reducers. We firmly believe in quality first. All links from raw materials to finished products are strictly supervised and controlled, which provides a CHINAMFG foundation for product quality. Our products are sold all over the country and abroad.

The harmonic reducer and other high-precision transmission components were independently developed by the company. Our company spends 20% of its sales every year on the research and development of new technologies in the industry. There are 5 people in R & D.

Our advantage is as below:

1.7 years of marketing experience

2. 5-person R & D team to provide you with technical support

3. It is sold at home and abroad and exported to Turkey and Ireland

4. The product quality is guaranteed with a one-year warranty

5. Products can be customized

Strength factory:

Our plant has an entire campus The number of workshops is around 300 Whether it's from the production of raw materials and the procurement of raw materials to the inspection of finished products, we're doing it ourselves. There is a complete production system

HST-III Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 6.2 | 0.6 | 20.7 | 2.1 | 7.9 | 0.7 | 40.3 | 4.1 | 7000 | 3000 | ≤30 | 10000 |

| 80 | 9 | 0.9 | 27 | 2.7 | 12.7 | 1.3 | 54.1 | 5.5 | |||||

| 100 | 9 | 0.9 | 32 | 3.3 | 12.7 | 1.3 | 62.1 | 6.3 | |||||

| 17 | 50 | 18.4 | 1.9 | 39 | 4 | 29.9 | 3 | 80.5 | 8.2 | 6500 | 3000 | ≤30 | 15000 |

| 80 | 25.3 | 2.6 | 49.5 | 5 | 31 | 3.2 | 100.1 | 10.2 | |||||

| 100 | 27.6 | 2.8 | 62 | 6.3 | 45 | 4.6 | 124.2 | 12.7 | |||||

| 20 | 50 | 28.8 | 2.9 | 64.4 | 6.6 | 39 | 4 | 112.7 | 11.5 | 5600 | 3000 | ≤30 | 15000 |

| 80 | 39.1 | 4 | 85 | 8.8 | 54 | 5.5 | 146.1 | 14.9 | |||||

| 100 | 46 | 4.7 | 94.3 | 9.6 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 120 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 160 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 25 | 50 | 44.9 | 4.6 | 113 | 11.5 | 63 | 6.5 | 213.9 | 21.8 | 4800 | 3000 | ≤30 | 15000 |

| 80 | 72.5 | 7.4 | 158 | 16.1 | 100 | 10.2 | 293.3 | 29.9 | |||||

| 100 | 77.1 | 7.9 | 181 | 18.4 | 124 | 12.7 | 326.6 | 33.3 | |||||

| 120 | 77.1 | 7.9 | 192 | 19.6 | 124 | 12.7 | 349.6 | 35.6 | |||||

| 32 | 50 | 87.4 | 8.9 | 248 | 25.3 | 124 | 12.7 | 439 | 44.8 | 4000 | 3000 | ≤30 | 15000 |

| 80 | 135.7 | 13.8 | 350 | 35.6 | 192 | 19.6 | 653 | 66.6 | |||||

| 100 | 157.6 | 16.1 | 383 | 39.1 | 248 | 25.3 | 744 | 75.9 | |||||

| 40 | 100 | 308 | 37.2 | 660 | 67 | 432 | 44 | 1232 | 126.7 | 4000 | 3000 | ≤30 | 15000 |

HSG Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | ≤20 | 15000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | ≤20 | 20000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | ≤20 | 20000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 7500 | 5600 | ≤20 | 20000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 7000 | 4800 | ≤20 | 20000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||

| 40 | 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 5600 | 4000 | ≤20 | 20000 |

Exhibitions:

Application case:

FQA:

Q: What should I provide when I choose a gearbox/speed reducer?

A: The best way is to provide the motor drawing with parameters. Our engineer will check and recommend the most suitable gearbox model for your reference.

Or you can also provide the below specification as well:

1) Type, model, and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Hst-I |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any disadvantages or limitations to using gear reducer systems?

While gear reducer systems offer numerous advantages, they also come with certain disadvantages and limitations that should be considered during the selection and implementation process:

1. Size and Weight: Gear reducers can be bulky and heavy, especially for applications requiring high gear ratios. This can impact the overall size and weight of the machinery or equipment, which may be a concern in space-constrained environments.

2. Efficiency Loss: Despite their high efficiency, gear reducers can experience energy losses due to friction between gear teeth and other components. This can lead to a reduction in overall system efficiency, particularly in cases where multiple gear stages are used.

3. Cost: The design, manufacturing, and assembly of gear reducers can involve complex processes and precision machining, which can contribute to higher initial costs compared to other power transmission solutions.

4. Maintenance: Gear reducer systems require regular maintenance, including lubrication, inspection, and potential gear replacement over time. Maintenance activities can lead to downtime and associated costs in industrial settings.

5. Noise and Vibration: Gear reducers can generate noise and vibrations, especially at high speeds or when operating under heavy loads. Additional measures may be needed to mitigate noise and vibration issues.

6. Limited Gear Ratios: While gear reducers offer a wide range of gear ratios, there may be limitations in achieving extremely high or low ratios in certain designs.

7. Temperature Sensitivity: Extreme temperatures can affect the performance of gear reducer systems, particularly if inadequate lubrication or cooling is provided.

8. Shock Loads: While gear reducers are designed to handle shock loads to some extent, severe shock loads or abrupt changes in torque can still lead to potential damage or premature wear.

Despite these limitations, gear reducer systems remain widely used and versatile components in various industries, and their disadvantages can often be mitigated through proper design, selection, and maintenance practices.

What factors should be considered when selecting the right gear reducer?

Choosing the appropriate gear reducer involves considering several crucial factors to ensure optimal performance and efficiency for your specific application:

- 1. Torque and Power Requirements: Determine the amount of torque and power your machinery needs for its operation.

- 2. Speed Ratio: Calculate the required speed reduction or increase to match the input and output speeds.

- 3. Gear Type: Select the appropriate gear type (helical, bevel, worm, planetary, etc.) based on your application's torque, precision, and efficiency requirements.

- 4. Mounting Options: Consider the available space and the mounting configuration that suits your machinery.

- 5. Environmental Conditions: Evaluate factors such as temperature, humidity, dust, and corrosive elements that may impact the gear reducer's performance.

- 6. Efficiency: Assess the gear reducer's efficiency to minimize power losses and improve overall system performance.

- 7. Backlash: Consider the acceptable level of backlash or play between gear teeth, which can affect precision.

- 8. Maintenance Requirements: Determine the maintenance intervals and procedures necessary for reliable operation.

- 9. Noise and Vibration: Evaluate noise and vibration levels to ensure they meet your machinery's requirements.

- 10. Cost: Compare the initial cost and long-term value of different gear reducer options.

By carefully assessing these factors and consulting with gear reducer manufacturers, engineers and industry professionals can make informed decisions to select the right gear reducer for their specific application, optimizing performance, longevity, and cost-effectiveness.

What industries and machinery commonly utilize gear reducers?

Gear reducers are widely used across various industries and types of machinery for torque reduction and speed control. Some common industries and applications include:

- 1. Manufacturing: Gear reducers are used in manufacturing equipment such as conveyors, mixers, and packaging machines to control speed and transmit power efficiently.

- 2. Automotive: They are utilized in vehicles for applications like power transmission in transmissions and differentials.

- 3. Aerospace: Gear reducers are used in aircraft systems, including landing gear mechanisms and engine accessories.

- 4. Robotics and Automation: They play a crucial role in robotic arms, CNC machines, and automated production lines.

- 5. Mining and Construction: Gear reducers are used in heavy machinery like excavators, bulldozers, and crushers for power transmission and torque multiplication.

- 6. Energy and Power Generation: Wind turbines, hydroelectric generators, and other power generation equipment use gear reducers to convert rotational speed and transmit power.

- 7. Marine and Shipbuilding: They are used in ship propulsion systems, steering mechanisms, and anchor handling equipment.

- 8. Material Handling: Gear reducers are essential in conveyor systems, elevators, and hoists for controlled movement of materials.

- 9. Food and Beverage: They find applications in food processing equipment like mixers, grinders, and packaging machines.

- 10. Paper and Pulp: Gear reducers are used in machinery for pulp processing, paper production, and printing.

These examples represent just a fraction of the industries and machinery that benefit from the use of gear reducers to optimize power transmission and achieve the desired motion characteristics.

editor by CX 2024-03-05

China Professional China Helical Worm S Series Gear Reducer of Speed sequential gearbox

Product Description

SC Transmission China helical worm S series gear reducer of speed

Model:37~97

Ratio:6.8~288

Input power: 0.12~22kW

Output torque:11~4900N.m

Product Description

1.1. S series: right-angle speed reduction gearing composed by helical gears, worms, and gears, optimized and designed according to international standard

1.2.High precision, high efficiency, fine classification in transmission ratio, wide range, large transmission torque, reliable performance, low noise, flexible installation, and convenient use and maintenance.

1.3. They are widely used in various low-speed transmissions, which are general basic parts of mechanical transmission.

| Housing material | Cast iron |

| Housing hardness | HBS90-240 |

| Gear material: | 20CrMnTi |

| Surface hardnesss of gear | HRC58°-62° |

| Gear core hardness | HRC33°-40° |

| Input/Output shaft material . | 40CrMnTi |

| Input/Output shaft hardness | HBS241°-286° |

| Shaft at oil seal postion hardness | HRC48 ° -55 ° |

| Machining precision of gears material | Accurate grinding 6-5 grade |

| Heat treatment | tempering, cementing, quenching etc |

| Efficiency | up to 90% |

| Noise(Max) | 60-68dB |

| Unit model | Foot mounted,flange mounted,hollow shaft mounted |

| Input method | flange input,inline input,shaft input |

| Vibration | ≤ 20um |

| Backlash | ≤ 20Arcmin |

| Bearing brands | NSK,C&U etc |

| Oil seal brands | NAK,SKF etc |

| Lubricant | VG680 |

| Motor | IP55, F class |

| Motor shaft | 40Cr, Tempering, cementing,quenching etc. |

Product Parameters

Company Profile

FAQ

Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Gear Shape: | Helical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do gear reducers enhance the efficiency of conveyor systems and robotics?

Gear reducers play a significant role in improving the efficiency of both conveyor systems and robotics by optimizing speed, torque, and control. Here's how they contribute:

Conveyor Systems:

In conveyor systems, gear reducers enhance efficiency in the following ways:

- Speed Control: Gear reducers allow precise control over the rotational speed of conveyor belts, ensuring that materials are transported at the desired speed for efficient production processes.

- Torque Adjustment: By adjusting gear ratios, gear reducers provide the necessary torque to handle varying loads and prevent overloading, minimizing energy wastage.

- Reverse Operation: Gear reducers enable smooth bidirectional movement of conveyor belts, facilitating tasks such as loading, unloading, and distribution without the need for additional components.

- Synchronization: Gear reducers ensure synchronized movement of multiple conveyor belts in complex systems, optimizing material flow and minimizing jams or bottlenecks.

Robotics:

In robotics, gear reducers enhance efficiency through the following means:

- Precision Movement: Gear reducers provide precise control over the movement of robot joints and arms, enabling accurate positioning and manipulation of objects.

- Reduced Inertia: Gear reducers help reduce the inertia experienced by robotic components, allowing for quicker and more responsive movements while conserving energy.

- Compact Design: Gear reducers offer a compact and lightweight solution for achieving various motion profiles in robotic systems, allowing for efficient use of space and resources.

- Torque Amplification: By amplifying torque from the motor, gear reducers enable robots to handle heavier loads and perform tasks that require greater force, enhancing their overall capabilities.

By providing precise speed control, torque adjustment, and reliable motion transmission, gear reducers optimize the performance of conveyor systems and robotics, leading to improved efficiency, reduced energy consumption, and enhanced operational capabilities.

Can gear reducers be used for both speed reduction and speed increase?

Yes, gear reducers can be utilized for both speed reduction and speed increase, depending on their design and arrangement. The functionality to either decrease or increase rotational speed is achieved by altering the arrangement of gears within the gearbox.

1. Speed Reduction: In speed reduction applications, a gear reducer is designed with gears of different sizes. The input shaft connects to a larger gear, while the output shaft is connected to a smaller gear. As the input shaft rotates, the larger gear turns the smaller gear, resulting in a decrease in output speed compared to the input speed. This configuration provides higher torque output at a lower speed, making it suitable for applications that require increased force or torque.

2. Speed Increase: For speed increase, the gear arrangement is reversed. The input shaft connects to a smaller gear, while the output shaft is connected to a larger gear. As the input shaft rotates, the smaller gear drives the larger gear, resulting in an increase in output speed compared to the input speed. However, the torque output is lower than that of speed reduction configurations.

By choosing the appropriate gear ratios and arrangement, gear reducers can be customized to meet specific speed and torque requirements for various industrial applications. It's important to select the right type of gear reducer and configure it correctly to achieve the desired speed reduction or speed increase.

What are the benefits of using a gear reducer in industrial applications?

Gear reducers offer several benefits that make them indispensable in various industrial applications:

1. Speed Reduction: Gear reducers allow the reduction of high-speed input from motors or engines to lower, more usable output speeds for specific applications, ensuring proper equipment operation and safety.

2. Torque Increase: By leveraging the mechanical advantage of gear ratios, gear reducers can significantly increase torque output, enabling the handling of heavy loads and providing the necessary power for tasks such as lifting, conveying, and processing.

3. Precise Control: Gear reducers enable fine-tuning of rotational speed and torque, providing precise control over machinery and processes, which is crucial in industries like manufacturing, material handling, and robotics.